Munich, Germany – BMW’s strategy for providing transportation involves what they describe as ‘three powertrain pillars’, internal combustion engines (ICE), hybrids, and electric motors. The trick with plug in hybrids and electric vehicles is to understand exactly how buyers intend to use them and make sure that there are a range of suitable vehicles to cover the needs of consumers.

BMW sees a range of hybrids and electric vehicles that complement the ICE powered cars they currently build. Some mild hybrids are already in production and available in a number of markets. Their plans include

hybrid vehicles that are used in ex-urban settings (inter city mobility) that receive a 20/50 kW electric ‘boost’ in addition to an ICE. Relying on minimal battery storage, the electric motor can be seen as being the

prime engine at low urban speeds and providing extra thrust to an economical engine when called on for passing or merging in an ex urban environment.

There is a PHEV under consideration that would boast a 40-80 kW electric motor and up to 15 kWh of battery storage. This would be geared more towards urban environments. And in a pure urban setting, a car like the i3 would shine.

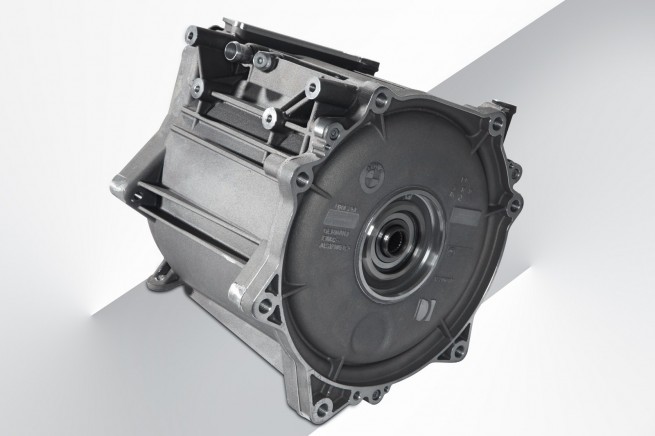

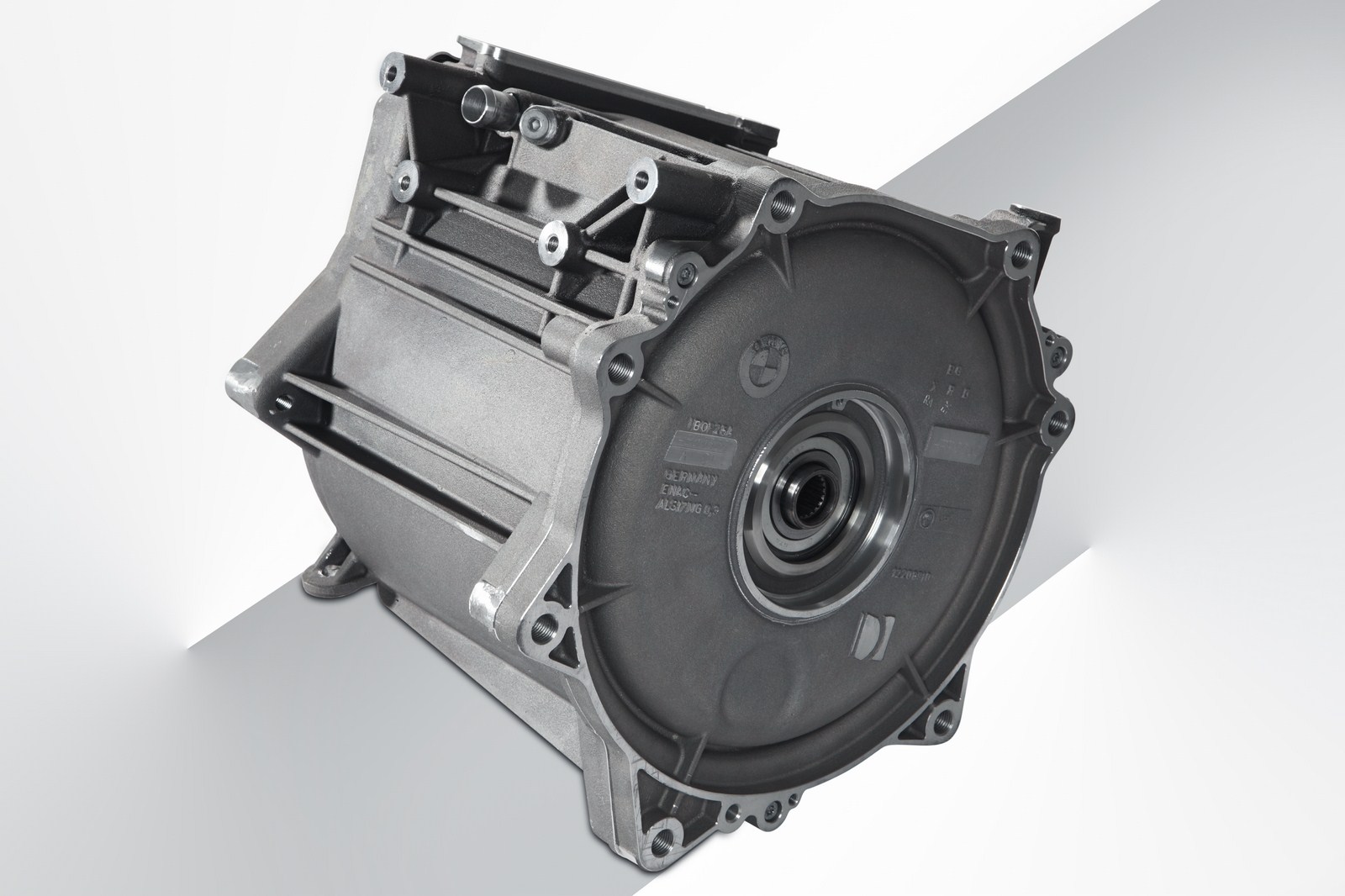

The big three components in electric vehicles are batteries, electronics, and the electric motors. Recently Bosch and Daimler announced that they have established a joint venture to produce electric motors. BMW is already producing their own electric motors internally.

BMW will use a hybrid synchronous motor to power their electrified vehicles. Hybrid in this case means that the motor uses a combination of permanent magnets and variable reluctance to provide power. (More to come in a future tech article.) But a hybrid synchronous motor can pack a lot of power into a small package.

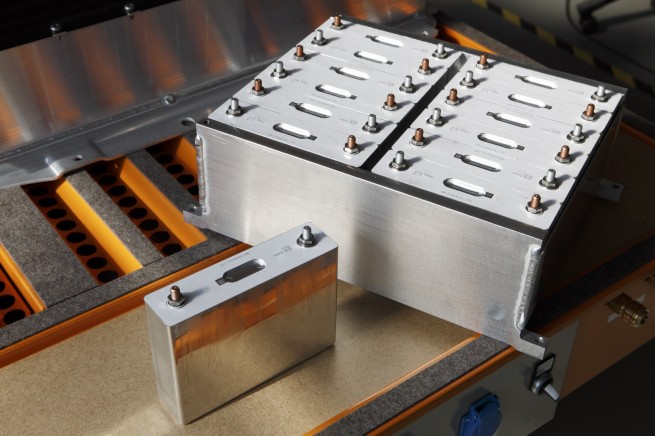

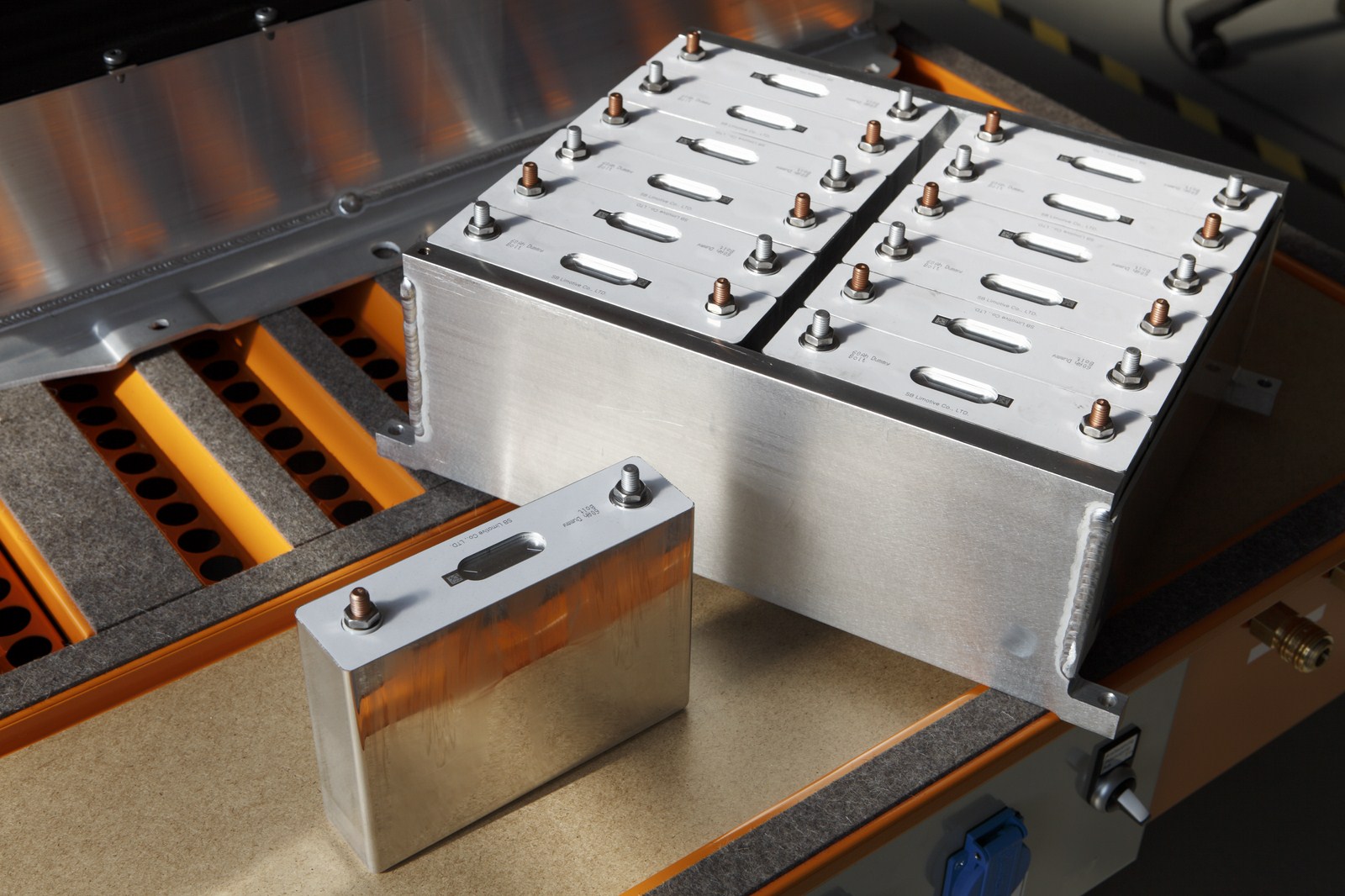

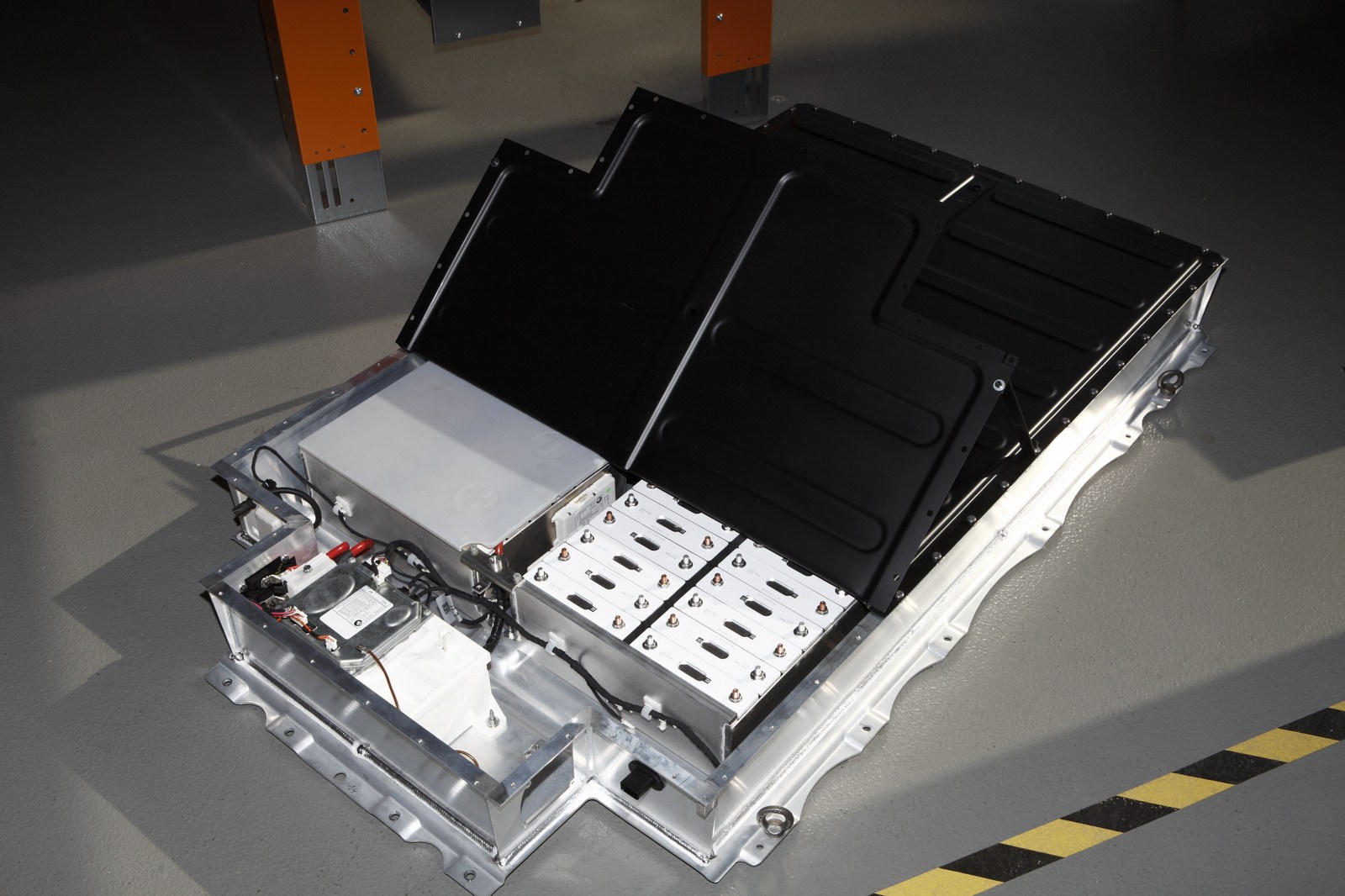

The battery packs are supplied by SB LiMotive and are lithium ion batteries, the individual cells producing 3.7 volts optimally. Full up voltage will be in the 250 to 400 volt range. The batteries are heavy and subsequently will be placed at the very bottom of the chassis in the i3. In addition they will be protected by deformable aluminum extrusions on the sides of the vehicle.

The lithium ion batteries have the storage capacity that BMW is currently looking for (pun intended). However, I believe BMW has passed up on going to a standardized plug-in battery configuration that some

manufacturers are proposing because they don’t want to be locked into a battery technology at this stage. There is some hope that newer battery solutions will deliver better energy density at a weight and space savings in the near future. Lithium polymer batteries are one such possibility.

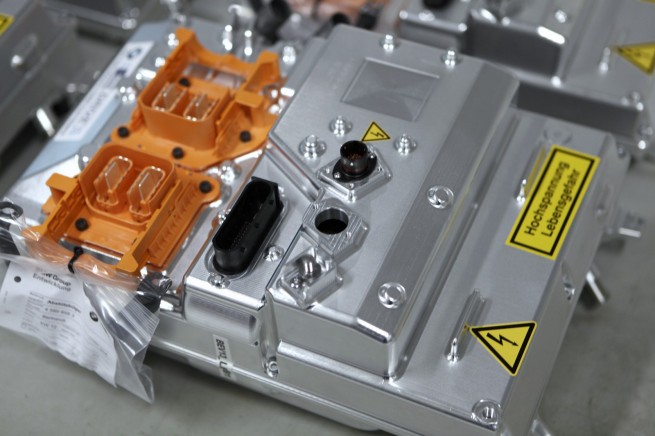

The last component is the electronics that keep all of the piece parts, batteries, DC current flow, AC current flow, brake energy regeneration, and a host of other items in sync. BMW is building these components in house also and did not spend much time discussing them during the presentation.

I asked about the torque curve of the motor, knowing that inductance can reduce torque output of the motor at higher RPM. I specifically asked about the torque curve falling off after about 5,000 RPM and was told that the torque curve was flat beyond that RPM. BMW is taking steps to provide a wide flat torque curve to the electric motors (evidently by mitigating the effects of inductance in the motor).

One telling point in the discussion about the cost of an electric powertrain is that 10 percent of 300 parts make up 75 percent of the cost of the powertrain. Subsequently the ability to build modules that can be shared among vehicles is critical to BMW.

This was a fascinating glimpse into the future of electric vehicles at BMW, the i3 of which we will see on the roads first. We are looking forward to sampling the i3 at the earliest opportunity.

See all of our coverage on Innovation Days 2011.