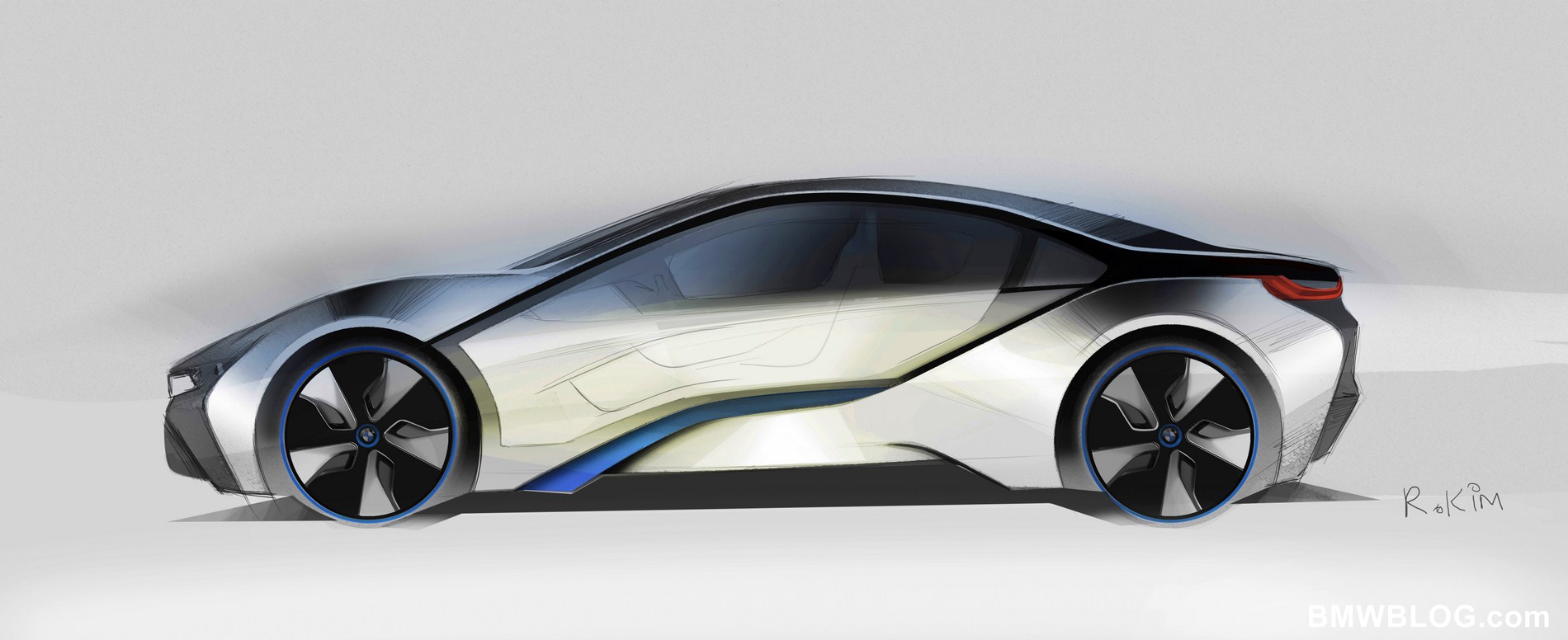

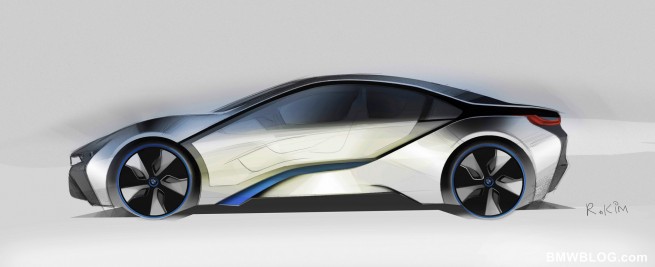

BMW “i” is a new sub-brand of the BMW Group that was introduced last year. Two vehicle concepts are getting close to roll out into the real world, with more other “i” vehicles in the pipeline. Both the i3 and i8 will bring a host of new technology, sustainable production methods and materials.

Adding to the already impressive family line of BMW cars, Rolls Royce, MINI and BMW Motorad, the i brand represents the company’s offering into the electric vehicles market, as well as hybrids. Running the i sub-brand as a separate entity, BMW will avoid losing focus from producing its normal series models, and at the same time, the company can focus on designing and engineering the i cars with “The Ultimate Driving machine” philosophy as well as EfficientDynamics.

We believe this new philosophy will drive the future of BMW and where all the other BMW cars are heading. We are already starting to hear about new technology being developed at BMW FIZ, such as “Tri-Turbos” coupled with smaller more displacement engines. The emphasis is still squarely on the “Driving Experience,” however “Efficiency” will play a greater part in how these new performers will impact our climate and resources.

BMW is taking a firm lead in this new field of efficient power with the turbo technology, variable valve lift and cam timing, and variable intake runners, producing glorious engines like the N63 V8; a 4.4 liter twin turbo V8 producing 400 horsepower while able to attain 25 mpg in the F10 550i. The latest N20 four-cylinder produces 240 horsepower while returning 30 mpg in the new Z4 sDrive28i. The pinnacle of the i brand cars will see the i8 Hybrid powertrain propel it to 62 mph in under 5 seconds while returning near 100 mpg capabilities.

Powerful efficient engines won’t be the only focus at BMW. Lightweight materials will also be a main focus in the new cars, not only in the BMW i cars, but in normal BMW series cars. First introduced in the limited production M3 CSL, CFRP (Carbon Fiber Reinforced Plastics) was used throughout with successful results. CFRP produced by BMW’s joint venture partner at the Moses Lake plant (USA) will be designed and implemented into majority of BMW Group automobiles and motorbikes.

The result of all this focus on Efficiency will result in lighter, safer cars while maintaining BMW’s legendary driver centric capabilities.