The Efficient Dynamics Innovation Days 2014 provide the first opportunities for test-driving the BMW X5 eDrive plug-in hybrid prototype and the BMW 5 Series Sedan, both of which are equipped with the latest generation of the proactive drive system. At the same time, ideas for future solutions in the field of lightweight design, aerodynamics and thermal management will be presented.

1. The Efficient Dynamics strategy: All-round vehicle efficiency, dynamic performance and intelligent energy management.

The Efficient Dynamics strategy goes back to a vision which took shape almost 15 years ago and which saw the BMW Group begin carving out a forward-thinking corporate strategy to maintain its products’ leading edge far into the future. In 2007 these activities were then gathered together under the banner of the Efficient Dynamics strategy. With every model they have since developed, the BMW engineers have aimed to produce an efficient overall vehicle, a dynamic powertrain and an intelligent energy management system. Efficient Dynamics is unique in the market in terms of its systematic dedication to these goals. It was largely down to Efficient Dynamics that the BMW Group was listed as the most sustainable automaker in the world in the Dow Jones Sustainability Index for eight years in a row.

Now, with this strategy integrated into the development of every single vehicle the BMW Group builds, Efficient Dynamics has long since shed the label of a “vision” to become an everyday reality.

More dynamic performance, less CO2 – standard on every model.

When it comes to reducing fuel consumption, vehicles of the BMW and MINI brands set benchmarks worldwide in the premium segment. No other manufacturer has reduced its vehicles’ CO2 emissions faster and more steeply than the BMW Group. In Europe, fleet fuel consumption was reduced by well over 25 per cent between 1995 and 2008, and for the period 2008 to 2020 the Group is targeting a further 25 per cent reduction, this time worldwide. As of February 2014, the model range of the BMW and MINI brands already includes 39 models with CO2 emissions of 120 grams or less per kilometre. And more than half a year early, well over 100 BMW Group models already meet the tighter emissions standards set by Euro 6, which is scheduled to take effect in September 2014.

BMW EfficientDynamics today – and in the future.

To meet present and future challenges on the rapidly evolving mobility front, and to take into account customer requirements while complying with both present and future statutory requirements, the BMW Group has chosen to adopt a broad and flexible approach. In a world of fast-expanding megacities, ever scarcer resources and stringent legal requirements, innovative concepts are urgently needed.

Future-ready powertrain technology.

The tailored mobility and powertrain concepts taking shape in the development departments of the BMW Group are closely focused on both current and future requirements. This will enable the BMW Group to offer innovation which is both evolutionary, in the form of highly efficient internal combustion engine vehicles, and revolutionary, in the form of all-electric vehicles for use in major cities. The line-up will be completed by low-emission plug-in hybrids for long-distance use. Within a longer-term horizon, the BMW Group is also working on hydrogen-based fuel cell technology with the aim of bringing a generous zero-emission driving range and very short refuelling times within reach even of its larger vehicles. With the Efficient Dynamics development strategy, the BMW Group is also equipped to meet the stringent regulatory requirements scheduled for 2020 in Europe and 2025 in the USA.

Lightweight design, aerodynamics, energy management.

Alongside innovative drive technologies, the key components of the Efficient Dynamics strategy comprise intelligent lightweight design, optimised aerodynamics and intelligent energy management systems. At the Group’s own dedicated Aerodynamics Test Centre, the most modern of its kind in the industry, finely honed and optimised aerodynamic designs are developed. At the same time, on the lightweight design front, CFRP (carbon-fibre-reinforced plastic) components are now being used for the first time in the world in series-produced cars – the BMW i models. Efficient Dynamics also focuses on a lowered centre of gravity, compact design of major components, which are mounted as close to the centre of the vehicle as possible, a balanced 50:50 axle load distribution, reduced kerb weight and optimal aerodynamic characteristics. All these features add to the sporty appeal of BMW Group models.

Driving enjoyment for the 21st century.

With their revolutionary concepts and solutions that symbolise the innovative thinking of the BMW Group, the models of the BMW i sub-brand are right at the cutting edge of the Efficient Dynamics strategy. The BMW i3, the first all-electric BMW, made its market debut in late 2013. With its LifeDrive architecture (consisting of a CFRP passenger cell and an aluminium module comprising the powertrain, battery and chassis components), cabin heating based on a heat pump, and efficiency-maximised energy management with ECO PRO drive mode, coasting function and Proactive Driving Assistant, this model provides an impressive example of perfectly integrated innovative technologies.

The BMW i8 sports car meanwhile – the first plug-in hybrid model from the BMW Group – is all set for market launch in spring 2014. This model offers the most concentrated incarnation of Efficient Dynamics to date, in which all the basic principles of this development strategy have been implemented systematically and more radically than ever before. The lightweight, aerodynamically optimised and perfectly balanced 2+2-seater combines the performance of an out-and-out sports car with compact-car consumption, to achieve an optimal balance between dynamism and efficiency, and between driving enjoyment and resource conservation. The BMW i8 epitomises driving pleasure for the 21st century.

Trendsetting technology transfer: from the BMW i8 to the BMW X5 eDrive.

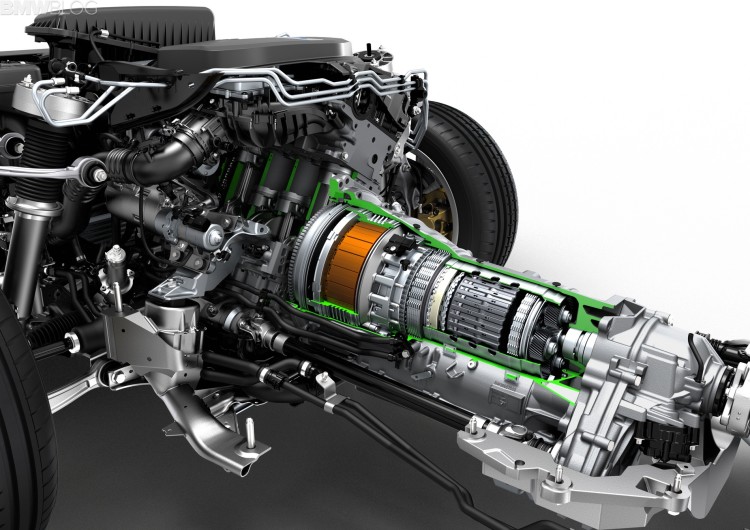

The plug-in hybrid powertrain of the BMW i8 combines a compact electric motor with a highly turbocharged TwinPower Turbo three-cylinder petrol engine from the new Efficient Dynamics engine family. This powertrain format offers potential for future technology transfers from the BMW i sub-brand to the BMW core brand. The future applications for plug-in hybrid technology will include a future BMW X5 eDrive model in which a four-cylinder TwinPower Turbo petrol engine and the plug-in hybrid system will for the first time be mated with the BMW xDrive intelligent all-wheel-drive system.

2. Technology transfer from BMW i to the BMW core brand: Harnessing BMW i8 plug-in hybrid technology in future BMW eDrive models.

Powertrain technology has always been a key pillar of the BMW EfficientDynamics strategy. With its dual focus on the continuous evolution of conventional internal combustion engines on the one hand and the development of new alternative drive concepts on the other, this strategy results in significant improvements in both the driving pleasure and the efficiency of all new models, coupled with substantial reductions in CO2 emissions. As well as achieving significant emissions reductions based on continuous evolutionary advances of the TwinPower Turbo petrol and diesel engines, future BMW core brand models will also benefit from the transfer of new electrified drive technology (BMW eDrive) developed by the BMW i sub-brand.

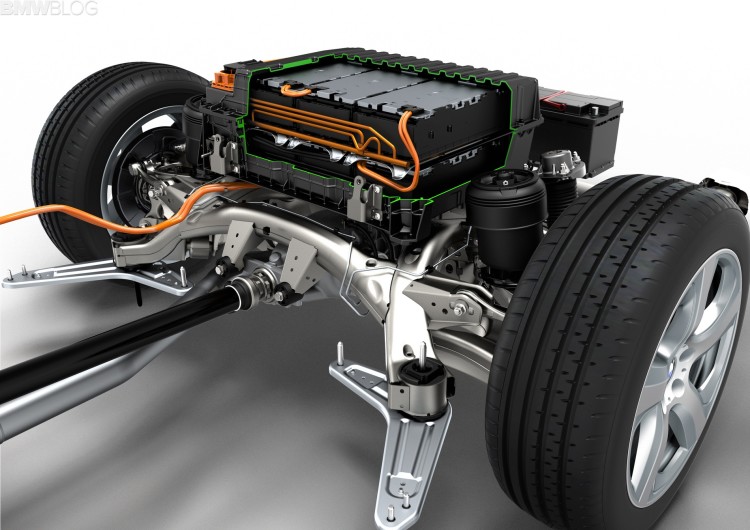

All BMW eDrive components are developed in-house by the BMW Group and customised as necessary to suit different powertrain applications. Current examples are the all-electric BMW i3 and the plug-in hybrid BMW i8. The BMW i8 is positioned right at the cutting edge of the Efficient Dynamics strategy. With its pioneering technology it is already setting standards, even though full-scale production has yet to begin. The technology used in the revolutionary powertrain concept of the BMW i8 will also find its way into vehicles of the BMW core brand.

Electric drive technology of the future: BMW eDrive.

Powertrain electrification will play a key role in paving the way to locally zero-CO2 mobility. “BMW eDrive” is the collective name for all drive concepts from BMW that are geared to achieving zero emissions at the point of use. The BMW Group has decided that the key components of this technology, such as the electric motor, high-voltage battery and power electronics, will be developed in-house. This ensures that the components are precisely matched to the specific requirements of specific vehicles in order to optimise not only performance, range and efficiency but also component lifetimes, safety and ease of maintenance.

The outstanding efficiency levels of as much as 96 per cent achieved by electric motors are unrivalled by internal combustion engines. At the same time, further features, such as the instant response of an electric motor and the powerful torque which it can produce virtually from standstill, are an ideal match for the dynamic personality of BMW models.

The plug-in hybrid powertrain of the BMW i8 combines the positive features of electric drive with the advantages of a highly turbocharged internal combustion engine. With its combined maximum output of 266 kW/362 hp, combined peak torque of 570 Nm (420 lb-ft), 0 – 100 km/h (62 mph) acceleration in 4.4 seconds, EU fuel consumption of 2.1 l/100 km (134.5 mpg) and CO2 emissions of 49 g/km, this plug-in hybrid sports car proves that it is possible to improve performance and reduce fuel consumption at one and the same time.

The electric motor provides a boost effect that assists the petrol engine when extra accelerating power is required. It can also act as the sole source of driving power, providing a maximum speed of 120 km/h (approx. 75 mph) and a range of up to 35 kilometres (approx. 22 miles). Its power is supplied by the lithium-ion high-voltage battery pack. The BMW i8 offers an optimal balance between performance and efficiency in a wide range of driving situations. During overrun, the high-voltage battery can be recharged via the electric motor. It can also be recharged by the electric motor when power demands allow. The high-voltage starter-generator, responsible for starting the engine, can also be used as a generator to charge the battery.

Plug-in hybrids are equally efficient whether used for short-distance or for long-distance driving, or a mixture of the two. Intelligent powertrain management ensures that both power sources always work together optimally. Power sharing between the internal combustion engine and the electric motor is managed in accordance with load and driving situation. Driver preferences are also taken into account, with a bias either towards sporty, dynamic performance characteristics or towards extra-energy-efficient operation of the overall system. To set these characteristics, the driver can choose from a range of pre-selectable driving modes, offering very dynamic, more comfortable or highly efficient operation.

BMW i technology will provide a boost for the BMW core brand.

Powertrain electrification has enormous potential for reducing fuel consumption and emissions – even for large, heavy vehicles – without compromising performance and dynamism. Quite the reverse, in fact: the boost function of the electric motor, whose additional drive torque supplements the internal combustion engine during low- and mid-range acceleration, significantly enhances the sporty driving experience. And as a further step in the Efficient Dynamics strategy, there are plans in the medium term to transfer the state-of-the-art powertrain technology of the BMW i8 to vehicles of the BMW core brand as well.

Plug-in hybrid system: coming soon to the BMW X5.

With the BMW Concept X5 eDrive model presented in September 2013 at the IAA in Frankfurt, the BMW Group highlighted a further way in which Sports Activity Vehicles can be made more efficient. For the first time the public were introduced to an SAV concept model which combines the BMW xDrive intelligent all-wheel-drive system with an innovative BMW plug-in hybrid system. This is a combination that not only gives the BMW X5 eDrive the typical BMW sporty temperament but equally turns the focus on efficiency and eco-friendliness. Thanks to the boost function of the electric motor, the SAV can deliver powerful acceleration and a 0 – 100 km/h (62 mph) sprint time of less than seven seconds. The development goal for this model is average fuel consumption of approximately 3.8 litres per 100 kilometres (74 mpg imp) in the EU test cycle, and CO2 emissions of 90 grams per kilometre – new benchmarks in this vehicle category. The vehicle is also capable of all-electric operation for up to 30 kilometres (over 18 miles), in which mode its produces no emissions at all at the point of use.

Thanks to perfect synchronisation of the BMW eDrive technology with the intelligent BMW xDrive all-wheel-drive system, the drive torque from the electric motor, the four-cylinder petrol engine or both power sources operating in tandem can be split in a variable ratio between the front and rear wheels. The split is automatically controlled to provide superior traction, optimal stability and highest standards of agility and performance under all conditions. At the same time there are no compromises on the customary luxurious driving experience offered by the BMW X5, or on its high standards of driveability in both short- and long-distance use.

Whereas the BMW i8 is fitted with the BMW Group’s highly turbocharged three-cylinder engine, the future BMW X5 eDrive will use a state-of-the-art four-cylinder petrol engine from the same family – the new Efficient Dynamics engine range with TwinPower Turbo technology. This demonstrates the BMW Group’s overall aim of providing a customised electric mobility solution in every model series.

The new generation of TwinPower petrol and diesel engines.

Although the BMW Group is continuing to press ahead with systematic electrification of its vehicles, which it sees as the drive technology of the future, it also sees further major potential on the conventional powertrain front. This is why BMW is continuously working to improve and refine its internal combustion engines – amongst other things for future use as a basic component in BMW hybrid powertrains.

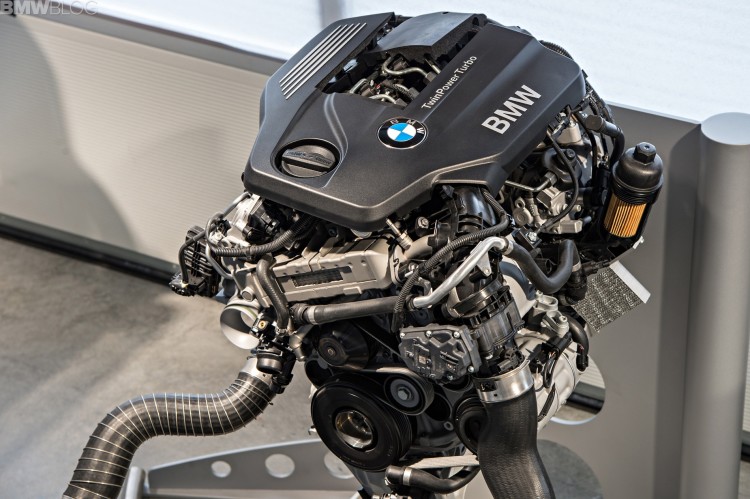

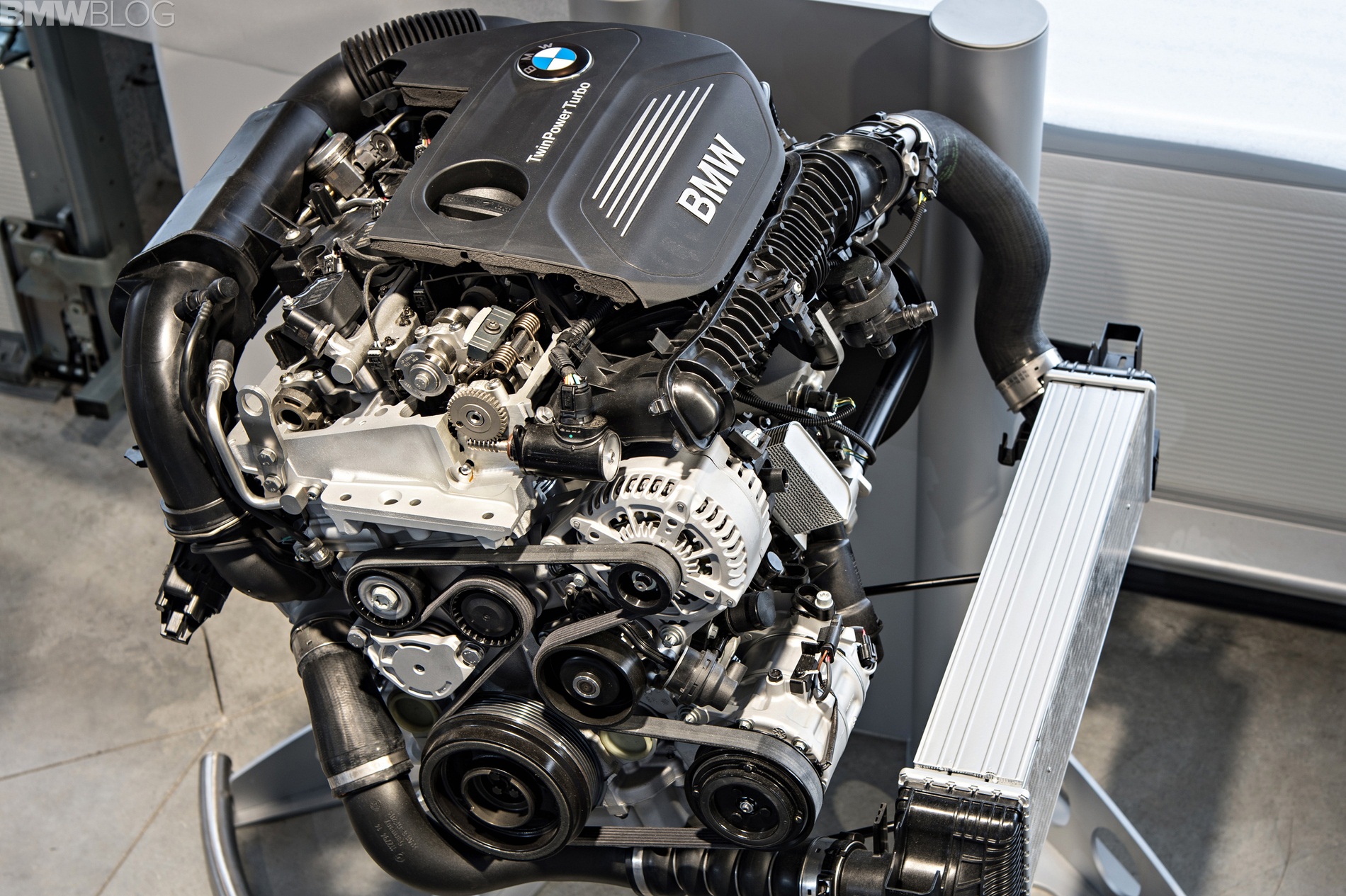

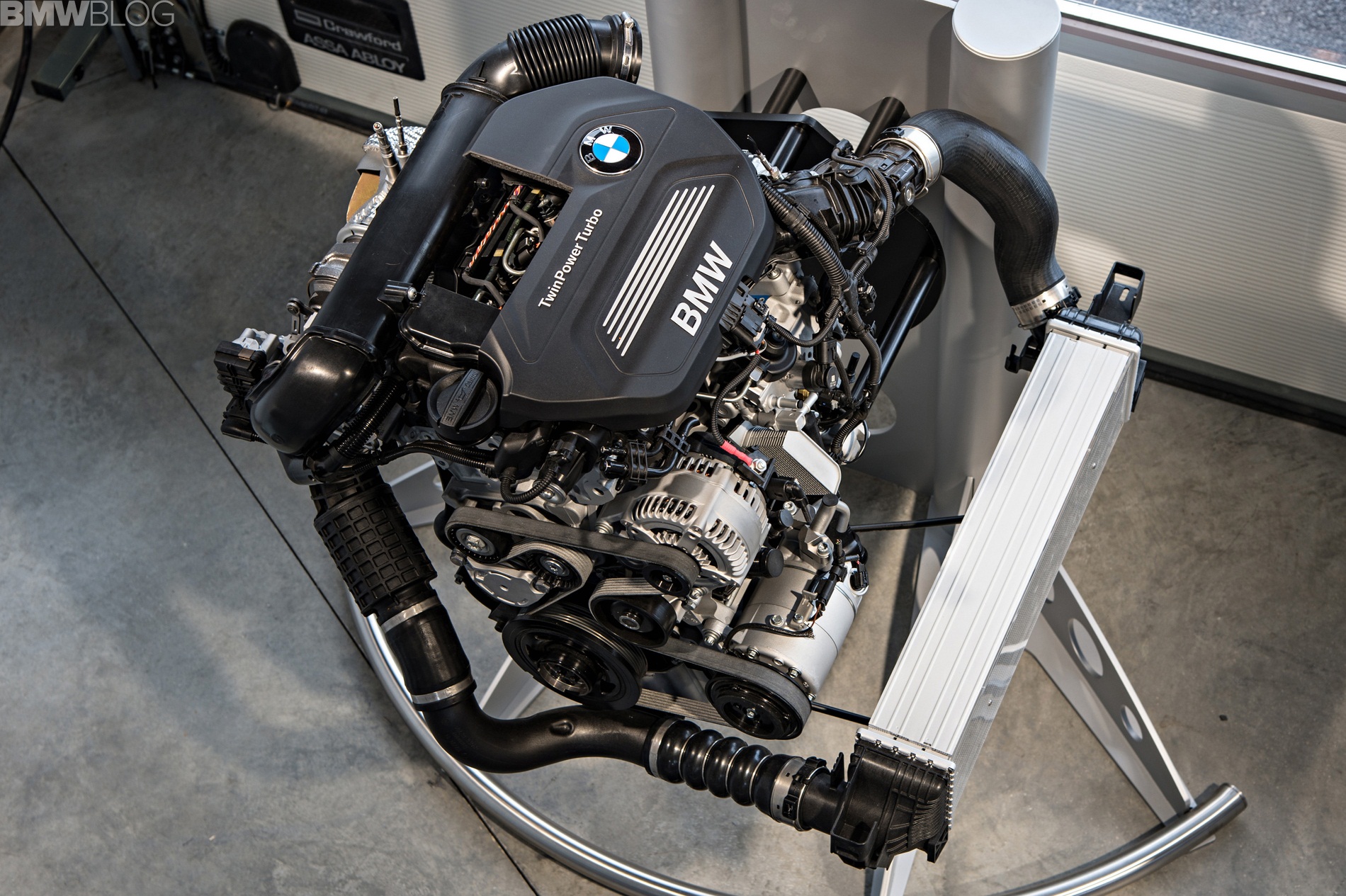

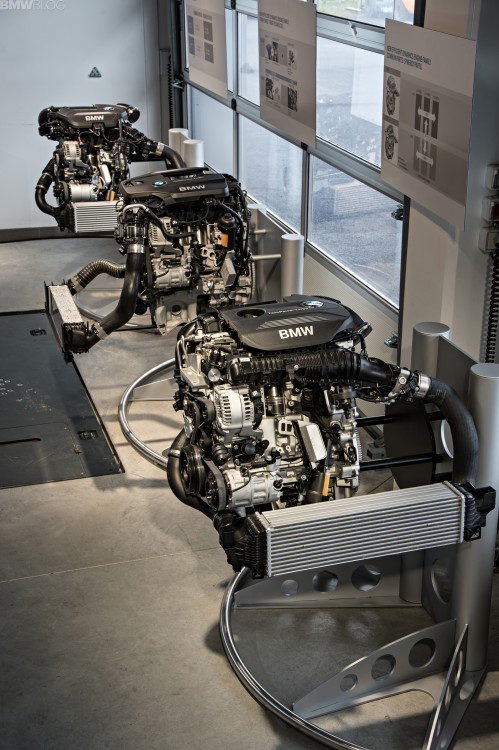

The further improved petrol and diesel engines from the BMW Group are the latest milestone in an evolutionary development process. The new Efficient Dynamics engine family comprises three-, four- and six-cylinder units and is based on a rigorous and methodical development process. By increasing the aluminium content and using the even lighter material magnesium, the BMW Group has also achieved substantial reductions in the average weight of the new engines. At the same time thermal management and acoustic properties have also been improved. The latest version of the multi-award-winning TwinPower Turbo technology continues to be a key feature of all these powerplants.

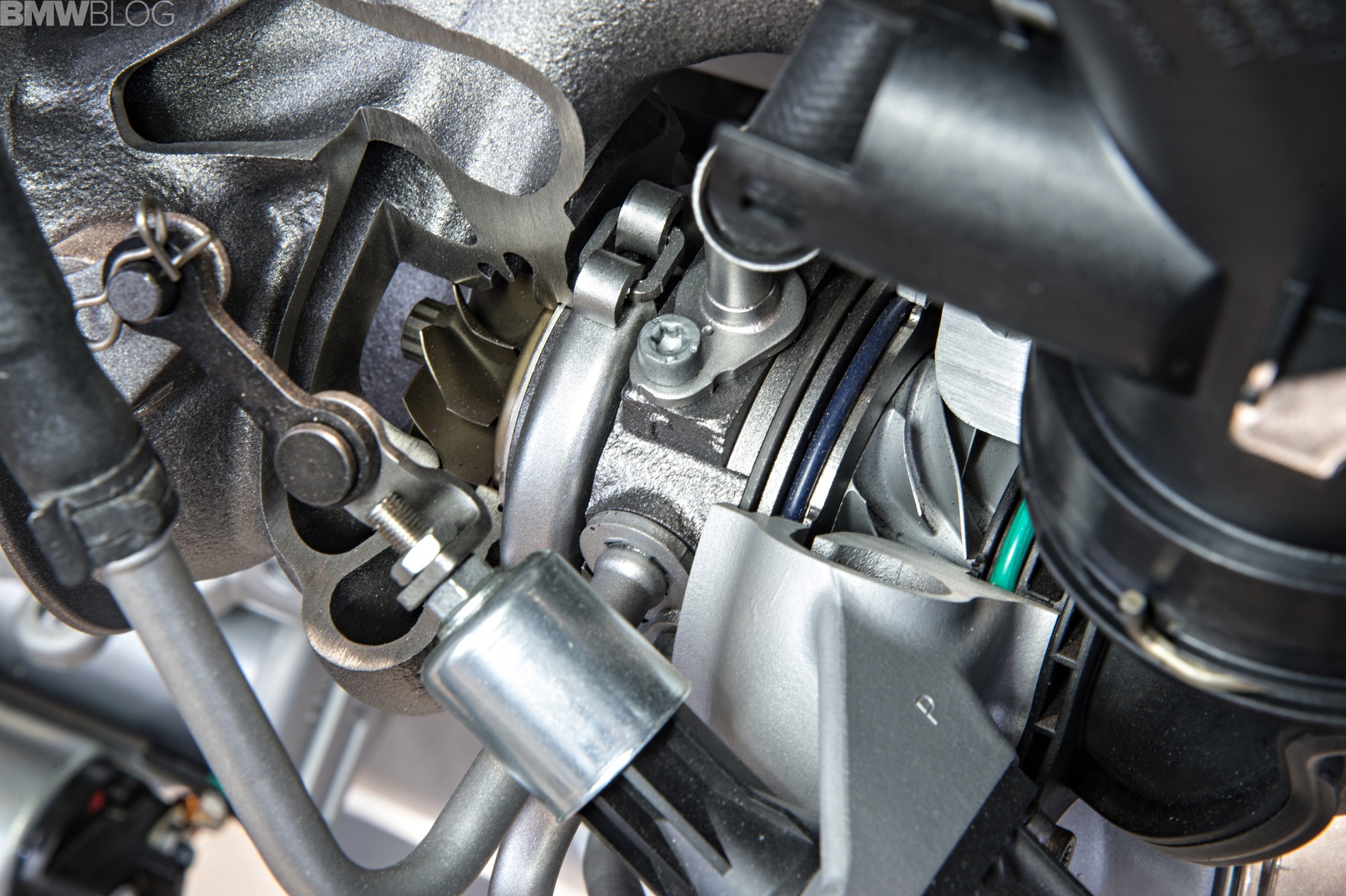

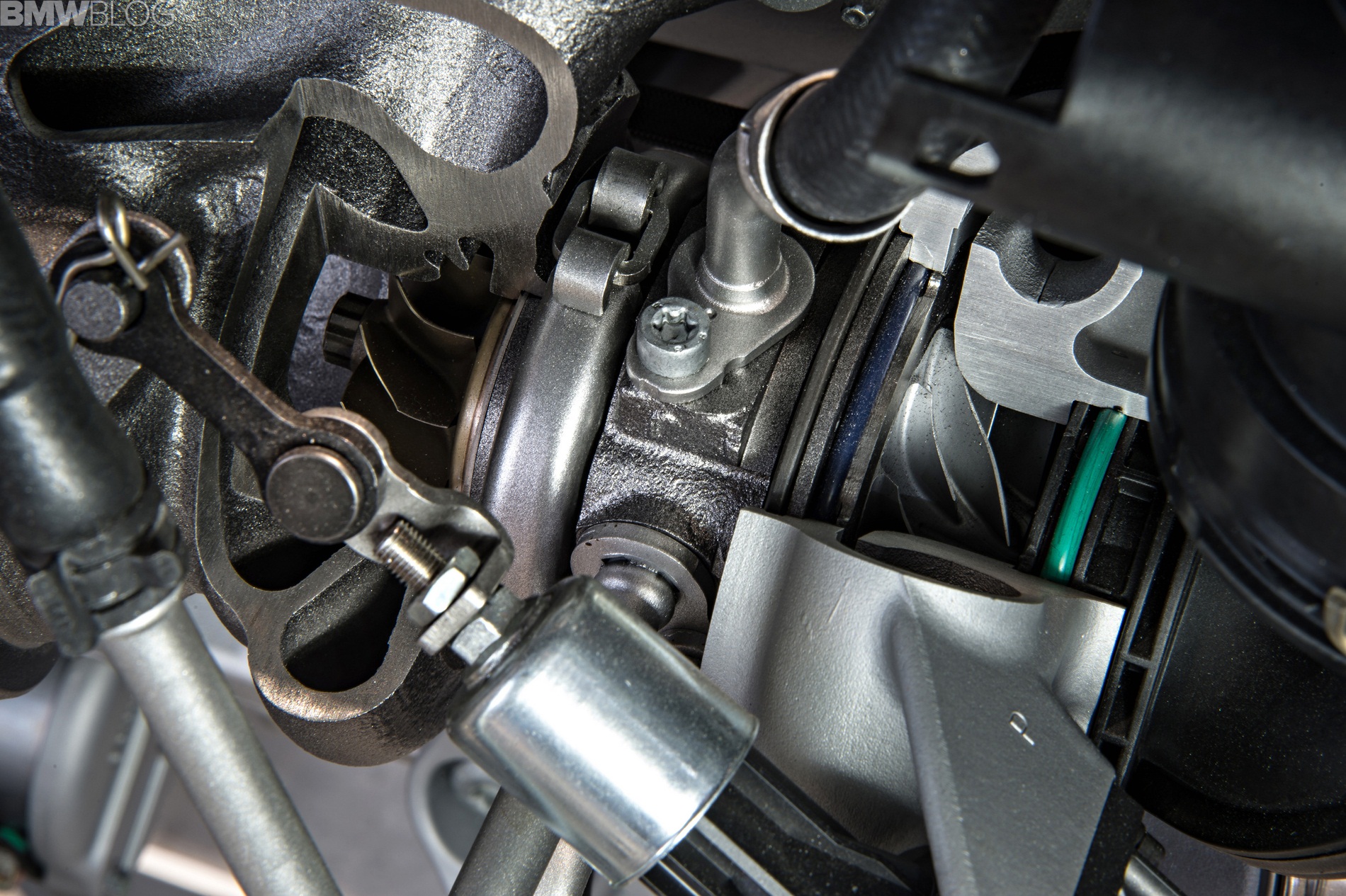

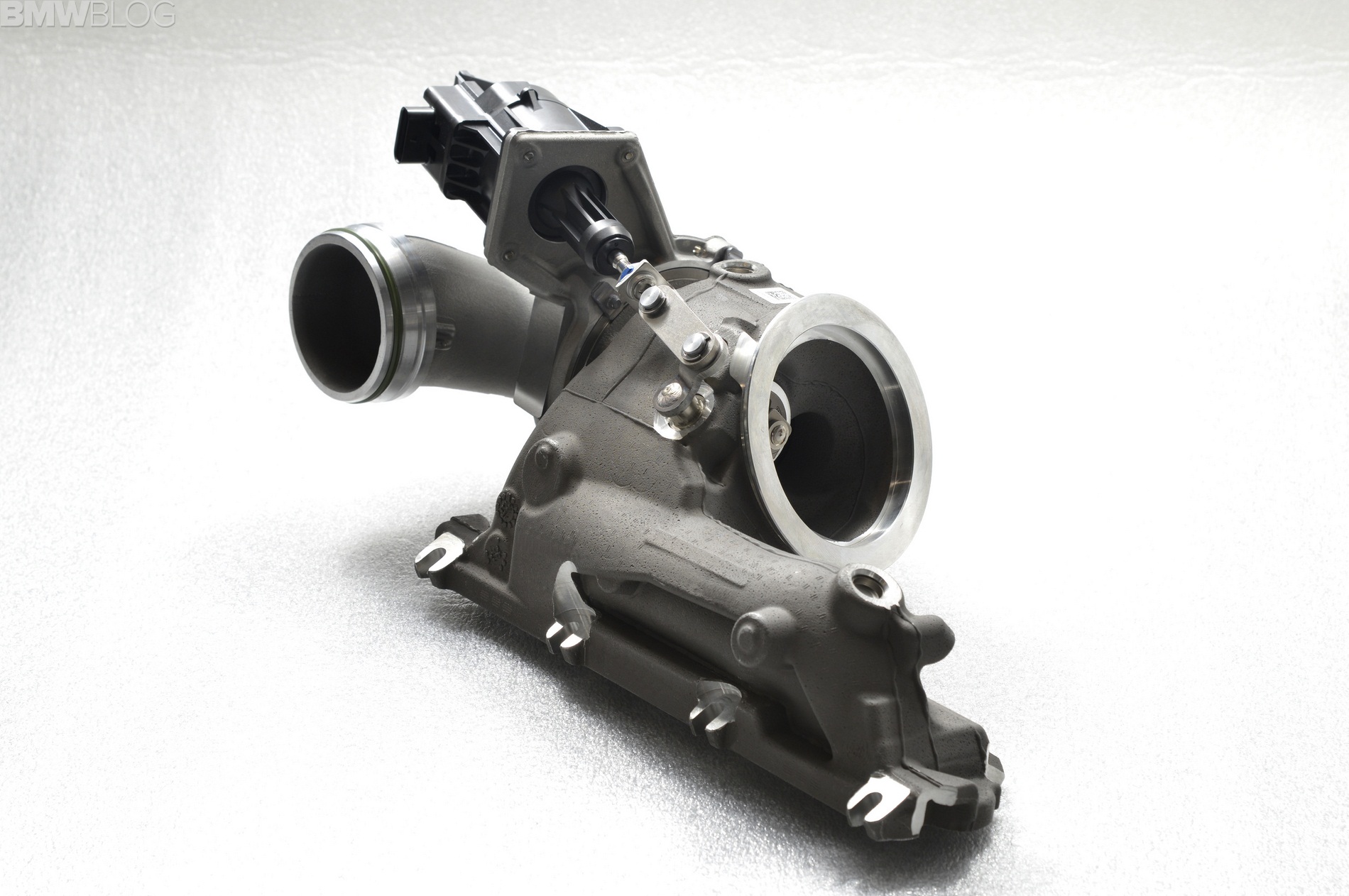

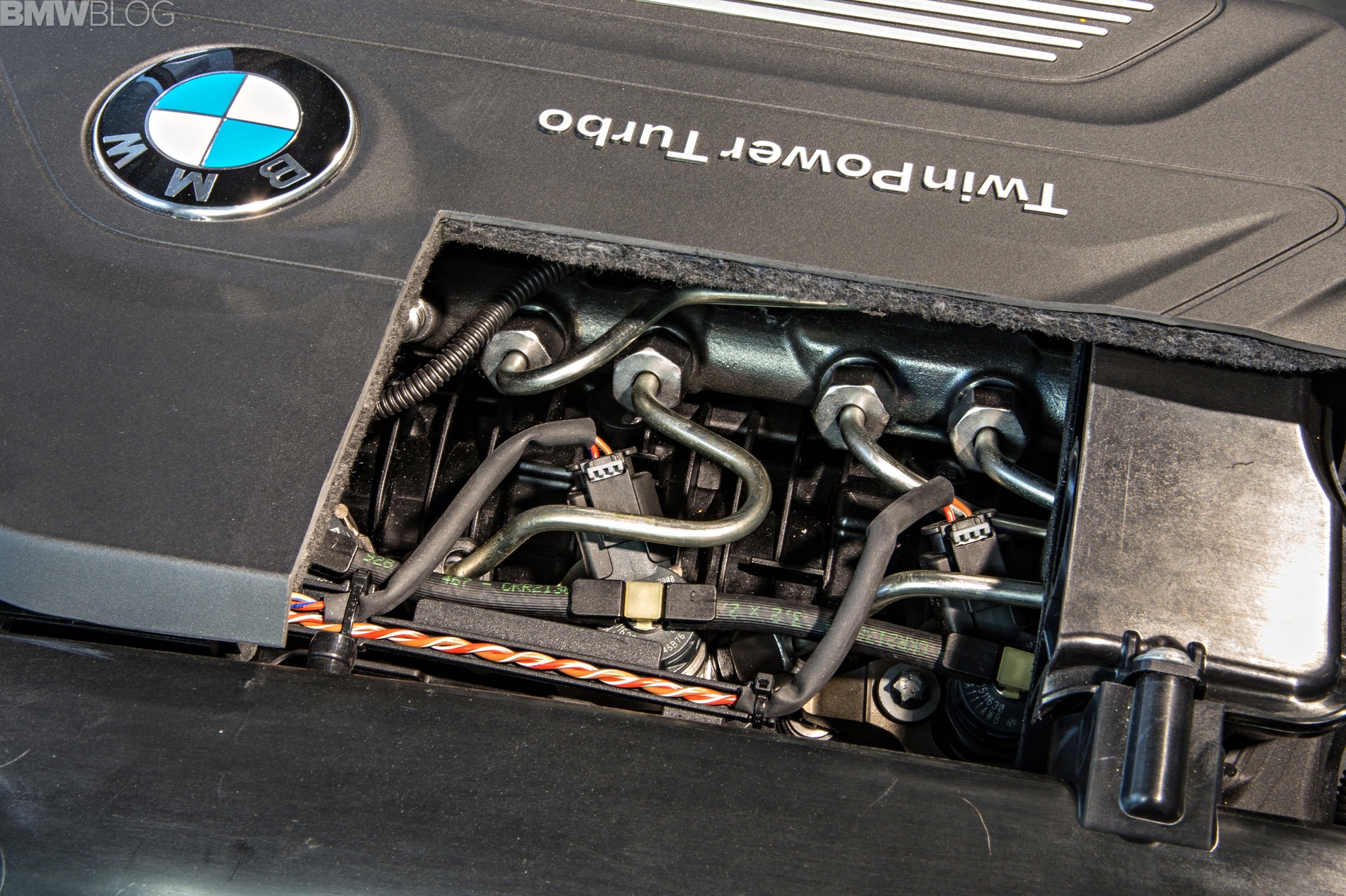

The first member of this new engine family, a 1.5-litre three-cylinder petrol engine, will make its debut in the BMW i8. This compact, highly turbocharged unit combines high levels of dynamic performance with outstanding efficiency, along with high-revving characteristics, instant response and a dynamic, sporty engine sound. Meanwhile, at this year’s Innovation Days the BMW Group will also present the first four-cylinder engines in this new engine family. These 2.0-litre engines with TwinPower Turbo technology will enter the market in the first half of 2014, in both petrol and diesel versions.

Fit for the future: TwinPower Turbo technology.

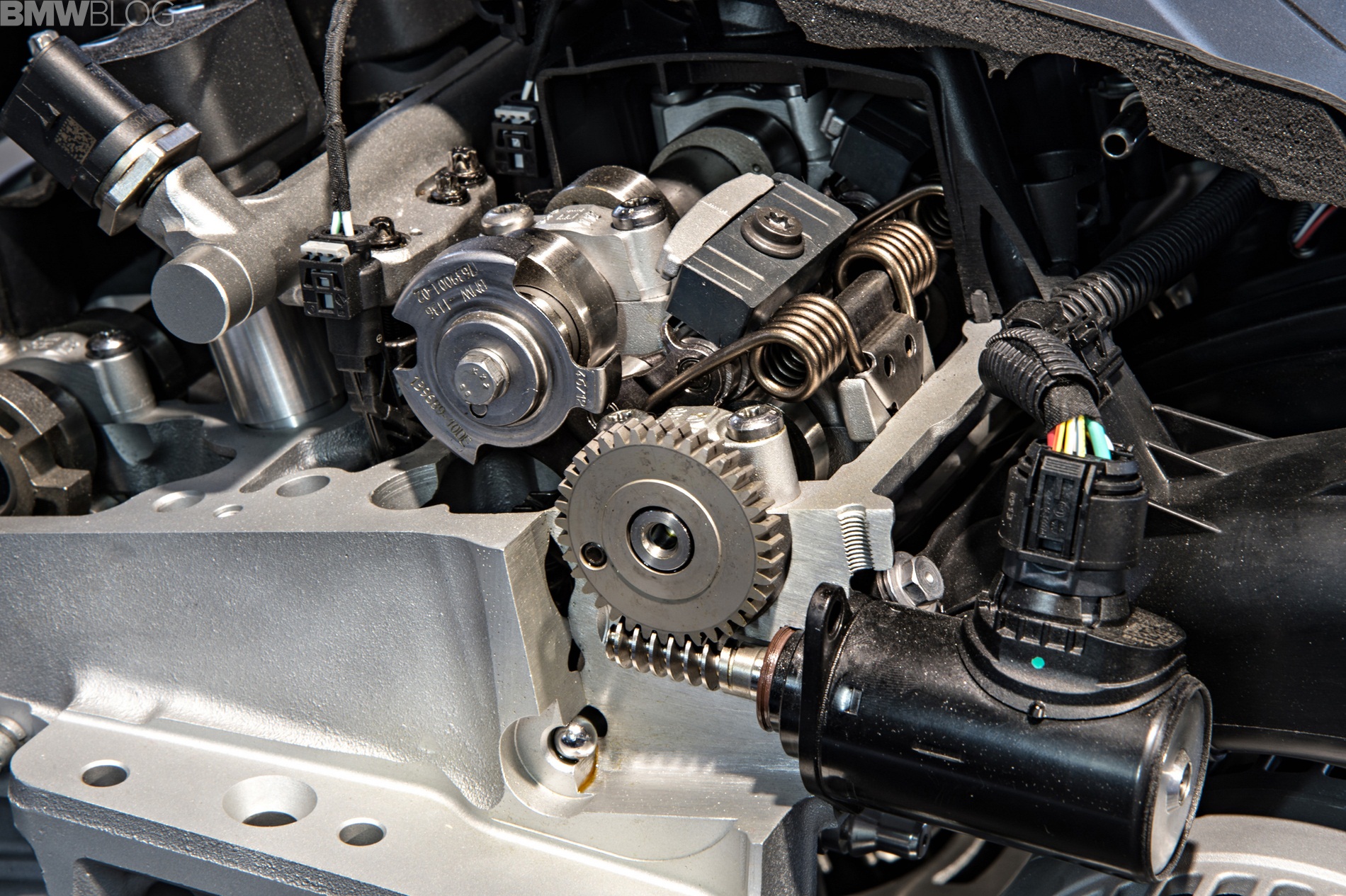

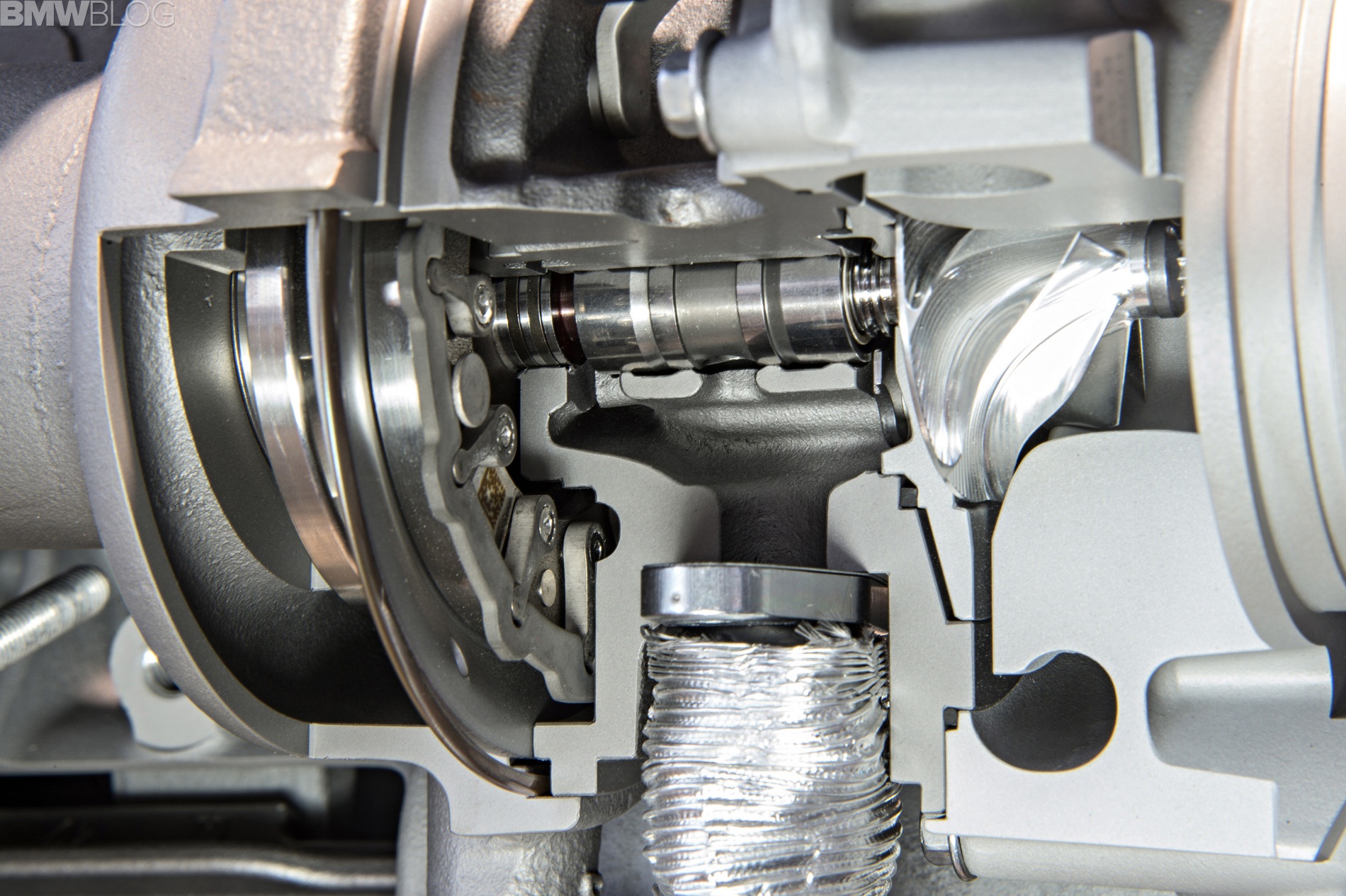

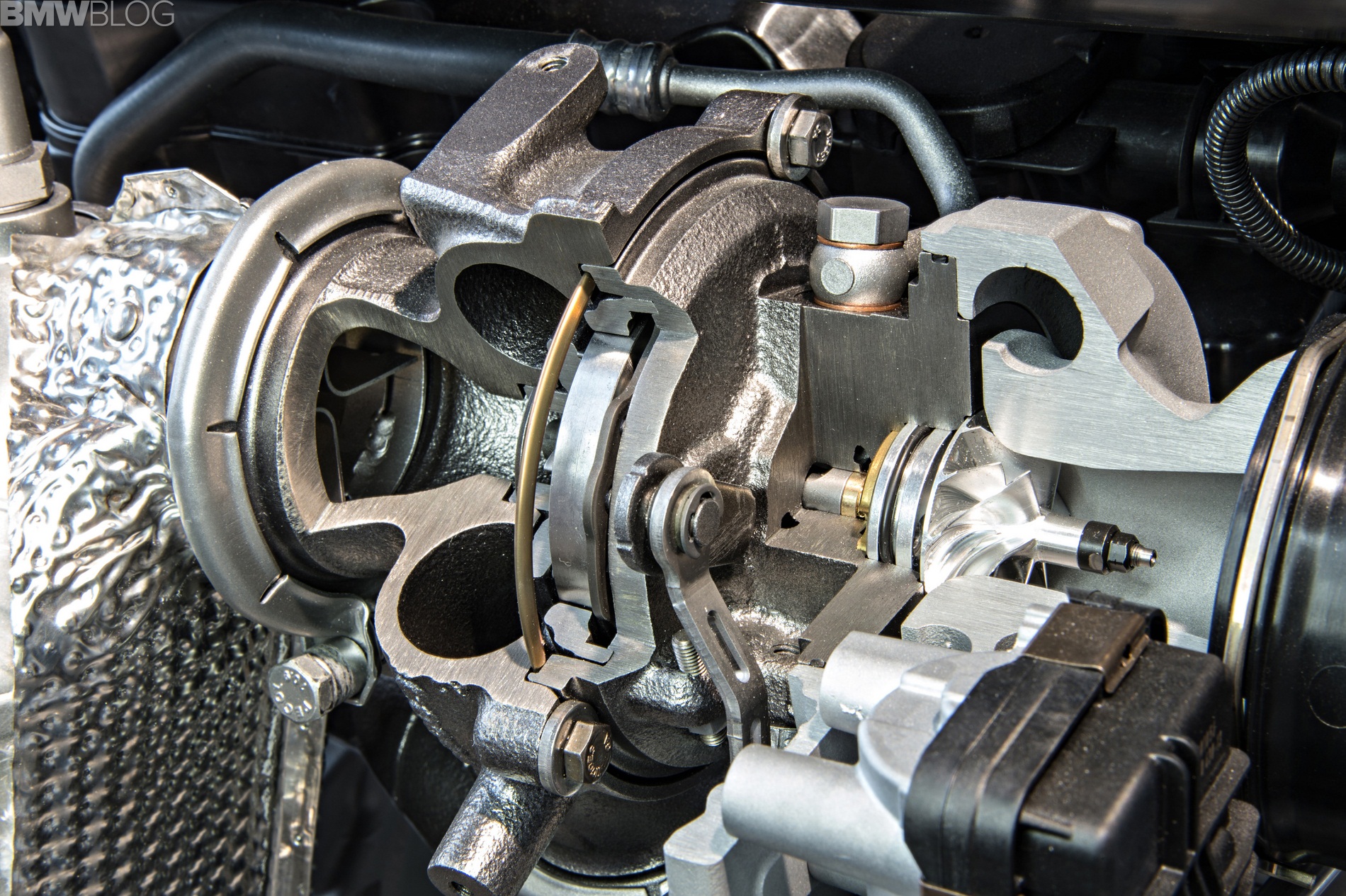

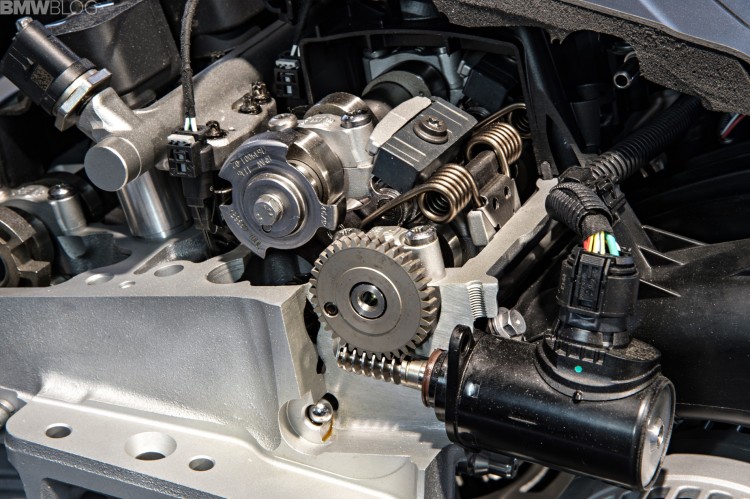

With its TwinPower Turbo technology, the BMW Group has for some years been offering an advanced high-tech engine concept which provides the basic format for the latest engine family as well. The term “TwinPower” stands for a combination of variable load control with state-of-the-art injection technology. TwinPower comprises fully variable components such as VANOS or Double-VANOS seamlessly variable camshaft timing, VALVETRONIC variable valve control and/or VNT (variable nozzle turbine) turbochargers on the diesel models. These are complemented by High Precision Direct Injection on the petrol models, with common-rail direct injection on the diesels, and finally by the third element in this high-tech concept, namely turbocharging. A standout feature of the petrol models continues to be VALVETRONIC throttle-free load control, which puts BMW TwinPower Turbo technology well ahead of competitor concepts – amongst other things also on the efficiency front.

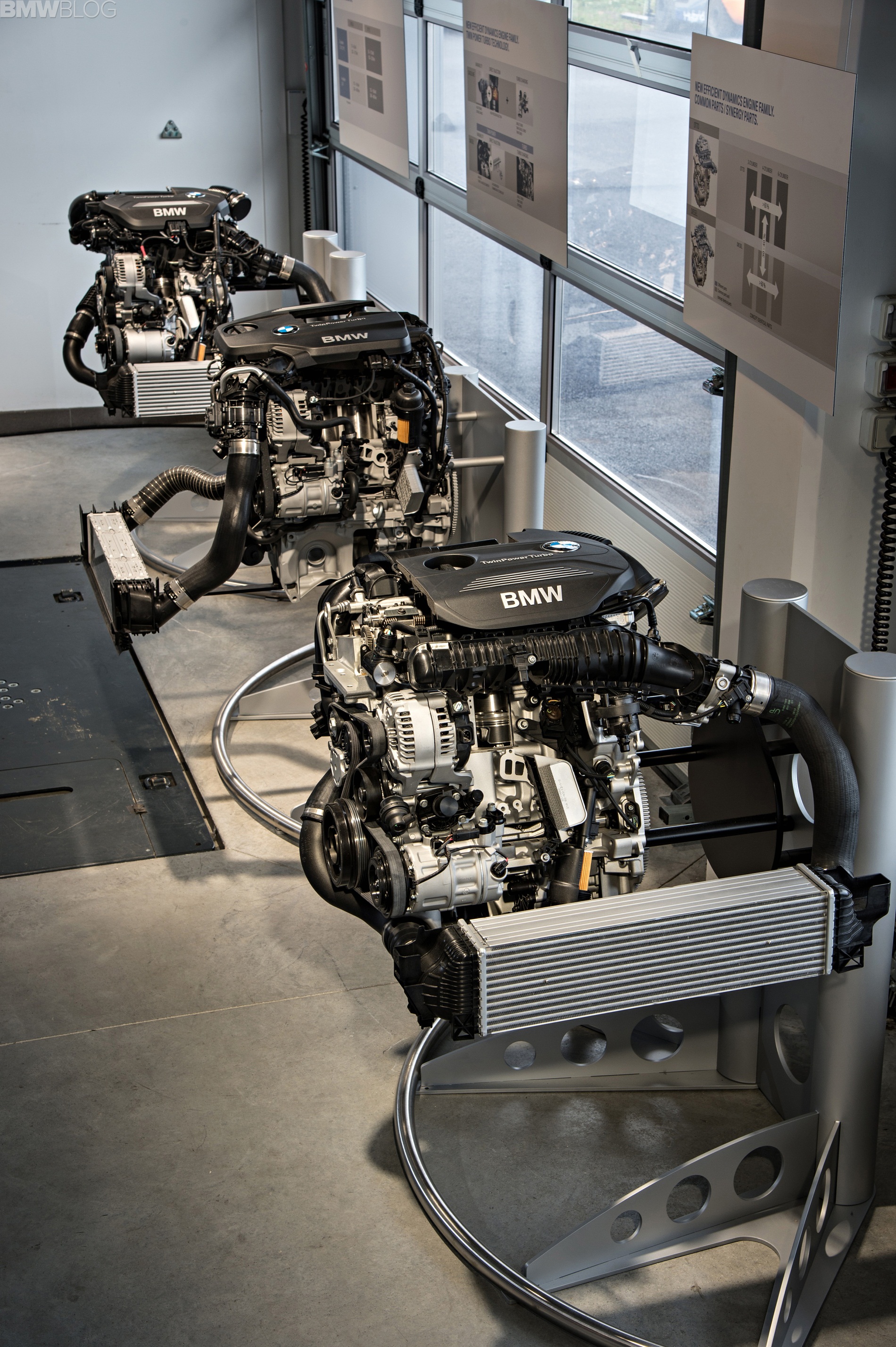

Complete line-up: three-, four- and six-cylinder engines.

Common to all units in the new engine family is their in-line configuration. The core engine comprises cylinders with an individual displacement of 500 cc, the optimal size for a passenger car engine. This means the new three-cylinder engine has a displacement of 1.5 litres, the four-cylinder engine 2.0 litres and the six-cylinder unit 3.0 litres. Thanks to construction commonality within a combustion type, the proportion of shared components has increased to as much as 60 per cent, while design commonality between petrol and diesel engines is approximately 40 per cent. Finally, all the engines run cold on the intake side and hot on the exhaust side. This is one reason why the three- and four-cylinder engines from the new family can be mounted either longitudinally or transversely in future BMW and MINI models.

Efficient development, flexible manufacturing, maximum quality.

With its new modular engine family, the BMW Group is able to develop three-, four- and six-cylinder engines with different power ratings that are perfectly adapted to different vehicle concepts. This makes it possible to achieve higher production volumes, leading to significant savings on development and production costs. At the same time the high level of design commonality between the engines makes it easier to develop additional versions and makes it possible to build relatively small volumes of such engines at short notice and cost-efficiently. As a result it is now possible for the first time at the BMW Group’s engine plants to build both petrol and diesel engines from the new family at the same time, on the same production line. That allows for flexible responses to variations in demand or in market trends.

For future models, therefore, the new modular engine family not only offers ecological sustainability, with its low fuel consumption and emissions, but also economic sustainability in terms of development and production.

3. Proactive drive system: BMW models that anticipate both route and driving situation.

An important element in the BMW Group’s Efficient Dynamics strategy is intelligent energy management. The aim is to avoid unnecessary energy consumption, which amongst other things means recuperating as much of the energy used by the vehicle as possible. In order to further improve the efficiency of its vehicles, thereby increasing their driving range, the BMW Group is continuing to systematically improve energy management across a range of vehicle components. Systems like the Auto Start Stop function – which automatically shuts down the engine to save fuel at red traffic lights or in stop-go traffic, and then restarts the engine immediately as soon as the vehicle can move off again – were first introduced many years ago and have since become standard on more and more BMW Group models. The same goes for braking energy recuperation.

The proactive drive system is based on the principle that energy should not be used unless it is actually needed. The idea behind this technology is that the vehicle should anticipate driving situations in advance, so that it can automatically prepare for upcoming requirements. The necessary information is supplied by the vehicle electronic system’s numerous sensors, the navigation system and, most recently, front-mounted radar and camera sensors.

Already, more and more models from all BMW Group model ranges are adopting this type of vehicle energy management, with navigation-based information allowing the transmission management and the Proactive Driving Assistant to identify the upcoming route and route profile, i.e. features such as uphill and downhill gradients and speed limits. This ability to “see ahead” allows the transmission to automatically select the correct gear in good time to suit the driving situation. Thanks to this technology, the different driving modes SPORT, COMFORT and ECO PRO are more clearly differentiated than on any other system on the market today. In line with the selected mode, the proactive drive system sets the vehicle up perfectly for the upcoming driving situation, while also taking into account driver preferences.

ECO PRO mode: maximum efficiency at the press of a button.

Depending on individual driving style, ECO PRO mode can achieve a reduction of up to 20 per cent in fuel consumption. A further five per cent saving can be achieved by using the coasting function, Proactive Driving Assistant and ECO PRO Route.

The Proactive Driving Assistant works in tandem with the navigation system to identify route features in good time. It takes into account speed limits, corners, the start of built-up areas, roundabouts, turn-offs and motorway exits. And based on the recorded driving data, the system also offers tips on a fuel-saving driving style.

In COMFORT and SPORT modes, the proactive drive system adapts the automatic transmission’s shift program to the driving situation. Whereas a conventional shift strategy is “blind” and only operates reactively, in response to throttle position and driving resistances, the Proactive Driving Assistant makes it possible to “anticipate” the route ahead and to adapt gear changes appropriately in real time.

The coasting function (on models with automatic transmission) disconnects the engine from the powertrain at speeds between 50 and 160 km/h (approx. 30 and 100 mph), allowing the vehicle to coast using only kinetic energy.

ECO PRO Route: the most efficient route to any destination.

When ECO PRO mode is activated, the BMW navigation system shows the driver not only the fastest and shortest routes to a given destination but also the most efficient. Taking into account the current driving situation and route profile, the system precisely calculates which route will offer maximum fuel savings with minimum loss of time. The driver can then decide whether he prefers to save time or fuel. The savings achievable on a particular route are shown as a percentage. In the event of congestion or other hold-ups on the selected route, the system will propose alternative routes. The route calculations also take into account, on a continuous, real-time basis, the driver’s individual driving style, based on vehicle fuel consumption in different driving situations.

ECO PRO Analyser: recording, learning, saving energy.

The ECO PRO Analyser, which is a standard component of ECO PRO mode, allows drivers to analyse their driving style at any time and to identify further potential for reducing fuel consumption. Before, during and after the trip, the driver can call up statistics in the ECO PRO Analyser to check how efficiently he is accelerating, decelerating and changing gear, and to see what sort of positive impact an improved driving style could have on fuel consumption and therefore also on range. The ECO PRO driving tips are intended to aid more fuel-efficient driving. Using BMW ConnectedDrive Services and the free-of-charge BMW Connected App, the recorded data can also be easily transferred to a compatible smartphone. A rating scale indicates the fuel efficiency of the driving style. This transparent analysis helps the driver to adopt more efficiency-oriented driving habits.

Unadulterated dynamism: the right gear every time.

Thanks to onboard radar and camera sensors, the third generation of the Proactive Driving Assistant is also able to incorporate the vehicle’s immediate driving environment into its operating strategy. This information allows the automatic transmission to adapt its shift strategy even more precisely to the current driving situation, for even greater efficiency. For example, the system can identify slower-moving vehicles in the lane ahead, as well as vehicles in neighbouring lanes. Strategically timed gear changes can then be performed which provide sufficient deceleration, even without braking, to prevent collisions with vehicles in front. At the same time, gear changes can provide the necessary power reserves for overtaking and dynamic lane changes.

The proactive drive system not only contributes to outstanding efficiency but also improves the dynamic characteristics of the vehicle, whether in ECO PRO mode, which is geared to maximum efficiency, in SPORT mode, where the automatic transmission uses a performance-biased shift strategy, or in COMFORT mode, which adopts a more relaxed, easygoing strategy.

If the vehicle is approaching a bend on a single-carriageway road outside built-up areas, the transmission automatically changes down to the most appropriate gear, if necessary making use of engine braking effect. All the necessary shift operations will have been completed by the time the vehicle enters the corner. If the system detects that another bend is coming up very soon, it identifies the radius of the corner and again selects the optimal gear. This ensures that higher engine braking power is available on approach. The power reserves available for subsequent acceleration are also increased, while unnecessary gearshifts and hunting between gears on or between bends is avoided. This high-precision strategy makes for more stress-free and dynamic driving and improves the overall driving experience. The proactive drive system works in a similar way at roundabouts, intersections, turn-offs and at slip roads on or off motorways. Regardless of the route specified in the navigation system, the proactive drive system also reacts to the use of the direction indicator.

Energy management of the future: energy in the cabin air harnessed to increase range.

Yet another innovative solution to emerge from the Efficient Dynamics stable is the use of the thermal energy content of the cabin air to increase the driving range of electrically powered vehicles.

On vehicles of today it is standard practice to simply release this heated or cooled cabin air into the environment once it has been circulated through the vehicle, despite the considerable amount of energy that has gone into bringing it to the desired temperature. When the air is expelled through the rear air vents, its residual energy simply goes to waste. Although this effect can be reduced, for example by recirculating the cabin air, in practice it can never be entirely prevented.

On all-electric vehicles (BEV) and plug-in hybrid electric vehicles (PHEV), however, intelligent use of energy is of paramount importance. Every watt of energy that can be saved, for example in the operation of ancillary units, can be supplied instead to the electric motor to increase the driving range.

BMW Group engineers are currently working on a process which extracts residual energy from the cabin air, using heat exchangers, before the air is released into the outside world. In a current research vehicle, this energy is then used to preheat air entering the vehicle heating system. This reduces the amount of energy needed to produce warm air, freeing up energy which can be used to drive the vehicle and thus to increase the zero-emission driving range.

4. Intelligent lightweight design and finely honed aerodynamics: Winning solutions in the quest for efficiency and sporty performance.

All new systems developed by the BMW Group are designed with an eye to optimal overall vehicle efficiency. Hallmarks of an efficient vehicle concept include intelligent lightweight design and optimal active and passive aerodynamics, geared to reducing driving resistances.

Intelligent lightweight design.

Lightweight design is an important component in the Efficient Dynamics strategy and has always been part of the BMW Group’s basic design philosophy. Vehicles of the BMW Group achieve an optimal balance between the requirements of the individual product and lowest possible specific weight.

Sporty vehicles should have a low centre of gravity and a balanced 50:50 axle load distribution, while their masses should be concentrated as far as possible at the centre of the vehicle and they should have a low weight for their specific market segment.

Intelligent lightweight design is important for ensuring the ideal balance between product requirements and lowest possible specific weight. At the end of the day, optimal overall efficiency can only be achieved on the basis of low-weight design, appropriate use of innovative materials and systematic use of material mixes that offer high standards of functional performance.

Intelligent lightweight design is implemented in every area of vehicle development at BMW, and in all assemblies and components. The vehicle body is a particular focus, since it continues to account for the largest fraction of total vehicle weight. That said, in addition to weight, advanced body design must also take into account functional aspects and dimensions. Through continuous evolutionary advances, the BMW Group engineers have repeatedly reduced the contribution of bodyshell weight to total vehicle kerb weight, despite simultaneous functional improvements in the area of safety and comfort. Greater body stiffness also has benefits in terms of reduced vibration and improved steering precision, while the simultaneous reductions in weight also make an important contribution to the efficiency and agility of the vehicle, and therefore also to driving dynamics. Increased use of aluminium and magnesium in the engine and chassis has been a further contributor to lightweight design. As a result, although many new BMW Group models may be larger than their predecessors, they are no heavier, and in many cases are actually considerably lighter. The third-generation BMW X5 models, for example, are up to 90 kilograms lighter than the comparable predecessor models – with important benefits for driving dynamics and fuel consumption.

Innovative use of materials in the BMW i3 and BMW i8.

Systematic lightweight design is particularly important on electrically powered vehicles, given that vehicle weight is one of two main constraints on vehicle range, along with battery capacity. For EVs, too, reduced weight means reduced energy consumption and improved driving dynamics. In order to offset the weight penalty of the electric components, the BMW Group came up with a rigorous lightweight design strategy for the BMW i brand in the form of the LifeDrive concept, an innovative vehicle architecture which for the first time combines an aluminium chassis and a CFRP passenger cell.

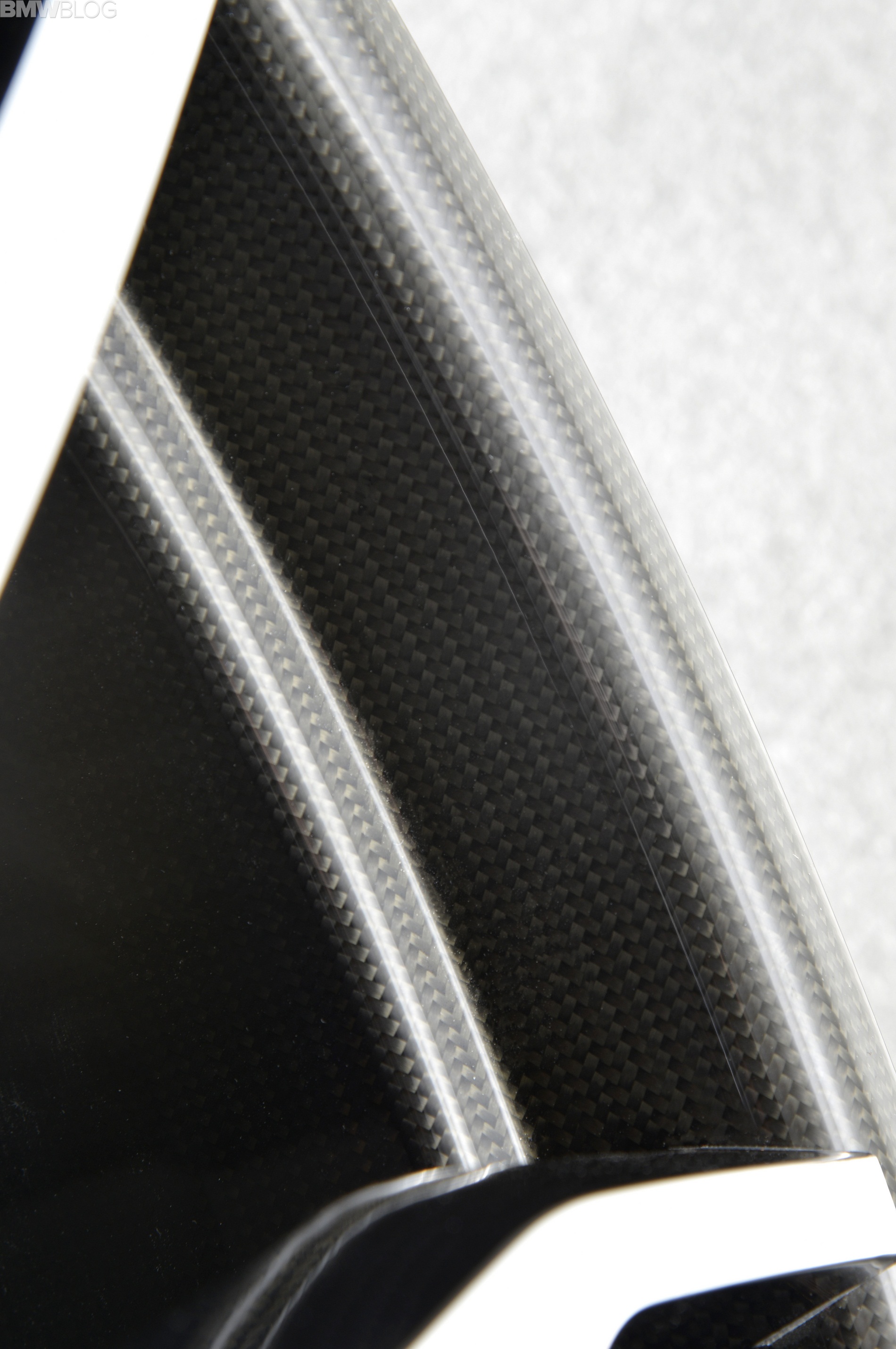

CFRP: high-tech material of the future.

Carbon-fibre-reinforced plastic (CFRP) boasts a particularly favourable strength-to-weight ratio and is therefore an ideal material for use in the vehicle body. For the same functionality, CFRP is around 30 per cent lighter than aluminium and 50 per cent lighter than steel. Used in the right places, this material therefore reduces weight, optimises the vehicle’s centre of gravity and improves body strength. This material is currently being used not only in the new BMW i3 and BMW i8 models: the sporty BMW M3/M4 and BMW M6 models have likewise been utilising the benefits of this high-tech material for some time. Components such as their roof and bumper supports are made of CFRP. The BMW Group is currently working on further potential applications, including the use of this material in rotating-mass components. Examples include hybrid aluminium/CFRP wheel rims, while CFRP’s high rigidity and low weight allow the CFRP propeller shaft on the BMW M3/M4 to be produced as a single-piece component, without a centre bearing. This results in 40 per cent weight savings over the previous model and reduced rotating masses, leading to further improved response.

In future, other BMW and MINI models will also benefit from this lightweight material in various ways. For example, production offcuts can be reprocessed into “secondary” (recycled-content) CFRP, which can be used to reduce the weight of components such as seat frames, instrument panel frames and spare wheels by up to 30 per cent, with simultaneous improvements in terms of cost-efficient, environmentally friendly manufacturing.

Technology leader in mass production of CFRP components.

After more than ten years of intensive research, resulting in improvements to processes, materials, production machinery and tools, the BMW Group has today become the first and only car manufacturer in the world with the necessary know-how to use CFRP in mass production. The processing technology used is unique and cycle times for even the more complex CFRP components are unusually short. The same is true of the specially developed bonding process used in the fully automated assembly of body parts.

As well as setting standards in the production of CFRP finished components, the BMW Group also attaches utmost importance to the use of environmentally friendly, resource-efficient and largely CO2-free processes in the manufacture and processing of the raw materials themselves. From fibre production right through to recycling of fibres and composites, the company is involved in all the various process steps in a state-of-the-art CFRP production chain that begins in Moses Lake in the USA and moves through Wackersdorf and Landshut to final assembly in Leipzig.

Reduced fuel consumption due to acoustic lightweight design.

On the engine front, too, innovative components are being developed which are further reducing not only the weight but also the noise emissions of petrol and diesel engines. Examples of acoustic lightweight design measures include belt drive sound insulation – the so-called engine front bulkhead, made of foam – and insulation measures which limit noise directly at source, such as oil sump encapsulation in which a fibre material is combined with a moulded foam layer.

Engine- and transmission-mounted encapsulation brings a radical improvement in the insulation of powertrain noise. Insulation at source has important benefits not only in terms of reduced weight but also of improved fuel efficiency, since engine heat conservation also helps to reduce fuel consumption. In this way a variety of synergies can be harnessed between interior/exterior noise reduction, thermal stability and heat conservation. Efficient powertrain noise reduction measures can reduce the amount of material used for such measures by almost 25 per cent – with corresponding benefits for vehicle weight.

Aerodynamics: improved efficiency and driving dynamics.

Bearing in mind the amount of powertrain energy which even at city speeds goes towards overcoming total aerodynamic drag (the product of the cd value and the frontal area of the vehicle), the coefficient of drag (cd) is generally regarded as a key indicator of the aerodynamic quality of a vehicle. At higher speeds, aerodynamic drag is the main resistance acting on the vehicle and, as such, becomes the biggest contributor to fuel consumption.

Not surprisingly, therefore, aerodynamics is an important component of the Efficient Dynamics development strategy and a further key to improving driving dynamics. Aerodynamic development work focuses not only on reducing aerodynamic drag but also on optimising lift forces, which has the effect of improving vehicle stability and enhancing the typical BMW driving dynamics. In addition, a further important goal of aerodynamics is the active optimisation of the cooling air supply to engine, transmission and brake system. With every new model generation, the BMW Group engineers always take big strides in all these areas.

Aerodynamic honing in the wind tunnel.

Every vehicle from the BMW Group undergoes aerodynamic honing in the ultra-modern, in-house BMW Aerodynamics Test Centre (ATC). ATC is the world’s most innovative facility of its kind in the automobile industry, capable of performing a wide range of highly realistic measurements and tests. By simulating and analysing different operating conditions in this way, it has been possible to make more intensive use of aerodynamics to improve the driving dynamics of production vehicles.

Proportions, optimisation and attention to detail.

In addition to the design of the vehicle’s exterior proportions, which is one of the most important aerodynamic levers, many smaller detailed measures, too, are required to achieve the desired overall aerodynamic end result. In particular, the fine-honing of the front and rear aprons, exterior mirrors, A-pillars, roof strips and door sills makes all the difference between good aerodynamics and excellent aerodynamics, while never detracting from the overall vehicle styling.

A further feature which has a significant influence on aerodynamic drag and lift forces without directly impacting the vehicle styling is the underbody design. Vehicles of the BMW Group feature an aerodynamically optimised underside with smooth-surfaced panelling in the area of the engine compartment, exhaust tunnel and tank. Aerodynamically optimised panelling is also fitted in areas such as the rear axle and rear silencer. These measures result in a high degree of underbody sealing and improved drag and lift.

Visible aerodynamic detailing includes the Air Curtains integrated in the front apron of many BMW vehicles. These produce a curtain of air which reduces turbulence and therefore also drag in the area of the front wheels. On some BMW models, the Air Curtains are complemented by so-called Air Breathers, which allow a defined portion of the incoming air in the wheel arch to be swiftly released again, as an additional drag-reducing measure.

Many years ago, a variety of BMW models were already fitted with adjustable radiator slats. Today the second-generation active air flap system manages the incoming cooling air in a way that is adapted even more closely to actual demand, automatically opening or closing the slats between the cooling air intake and the radiator depending on a range of different parameters. This minimises drag, optimises engine cooling and improves cold start performance under all operating conditions. The reduced drag, and the fact that the engine is kept at its optimal operating temperature at all times, saves fuel and at the same time reduces CO2 emissions.

Best in segment: the aerodynamics of the new BMW X5.

Like the new BMW i8, whose drag coefficient (cd) of 0.26 is an outstanding value for the sports car segment, the BMW X5 provides a further, up-to-the-minute example of how production vehicles can benefit from the Efficient Dynamics strategy. Its coefficient of drag has been reduced by ten per cent compared with the predecessor model, giving this large BMW SAV a best-in-segment cd value of 0.31.

Overall, a vehicle’s exterior proportions and styling produce approximately 40 per cent of its total aerodynamic resistance. Particularly on vehicles with steep rear ends, like the BMW X5, the biggest potential for aerodynamic improvement is on the styling front. Among the solutions the engineers came up with here are new-design aerodynamic C-pillar extensions in the form of “aero blades”, situated on either side of the rear window and connecting with the roof spoiler. The resulting well-defined trailing edge reduces the rear vacuum effect and associated braking effect, thereby significantly improving drag.

At the wheel arches, too, an area which accounts for between 20 and 25 per cent of total aerodynamic resistance, an innovative package of measures comprising Air Curtains, Air Breathers and aero wheels optimises aerodynamics and reduces drag. Finally, active air flap control across all operating situations cuts fuel consumption and emissions through improved aerodynamics and optimised thermal management.

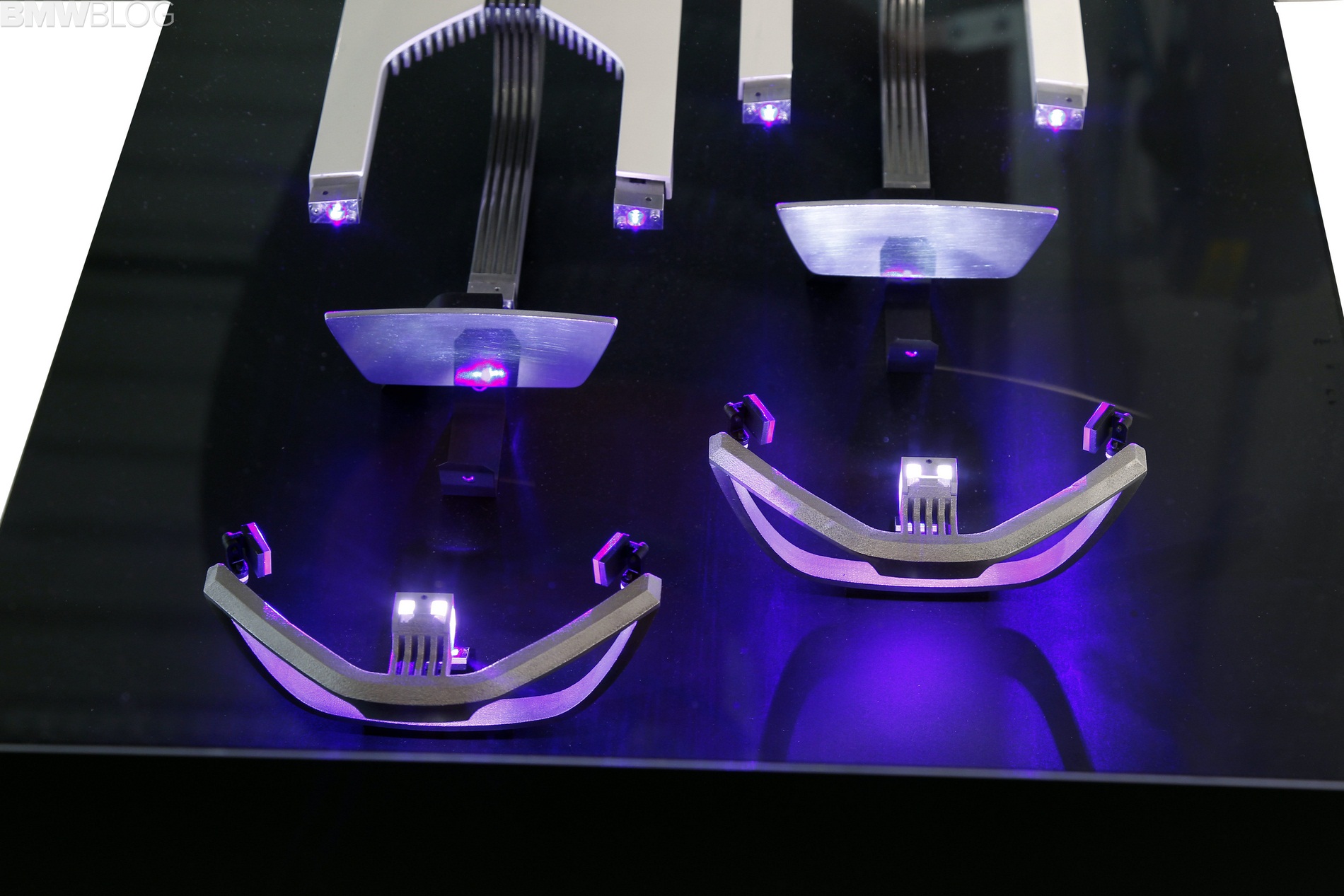

5. Innovative lighting technology: Globally unique laser headlights.

Full-LED headlights as standard, globally unique laser light available as an innovative option.

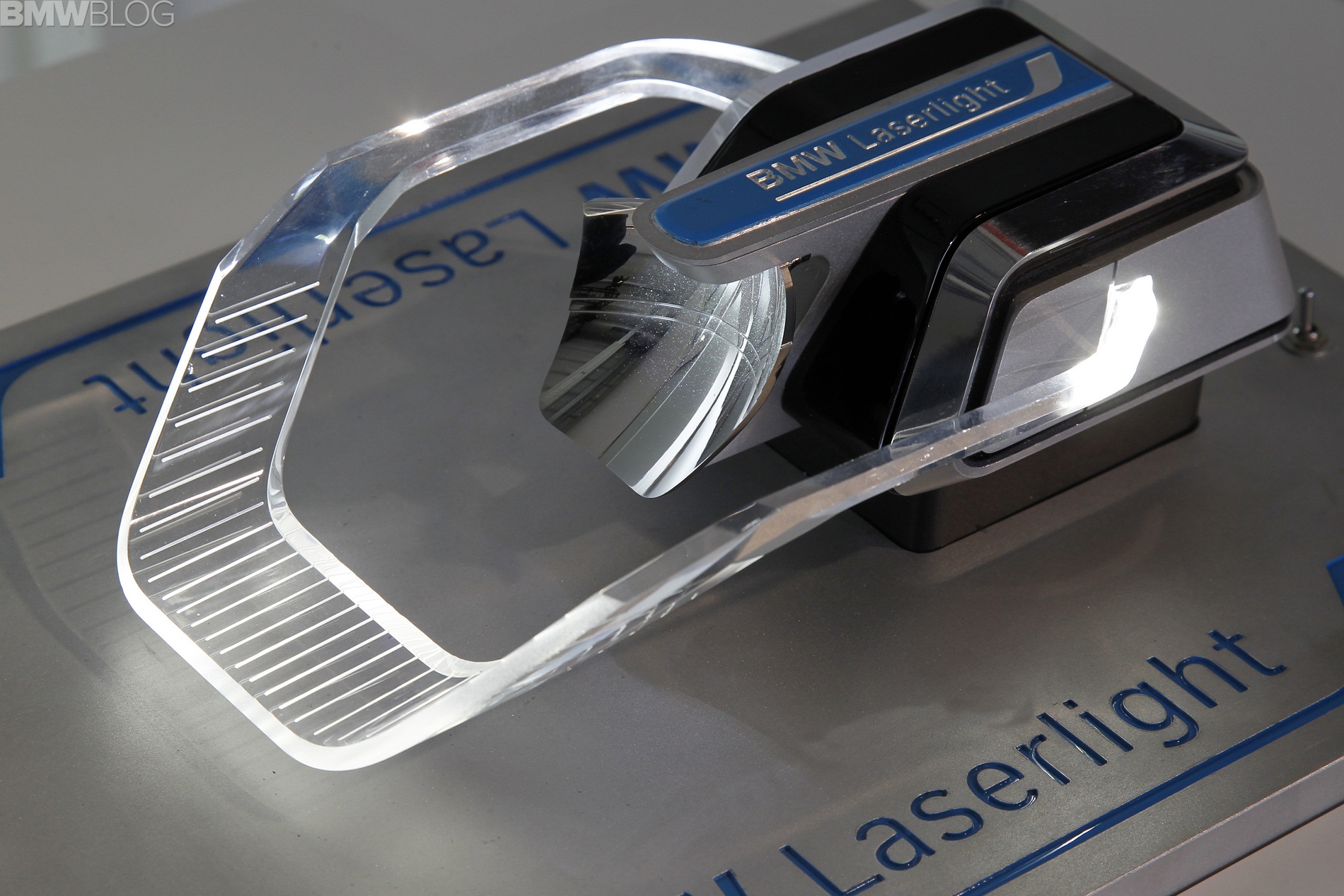

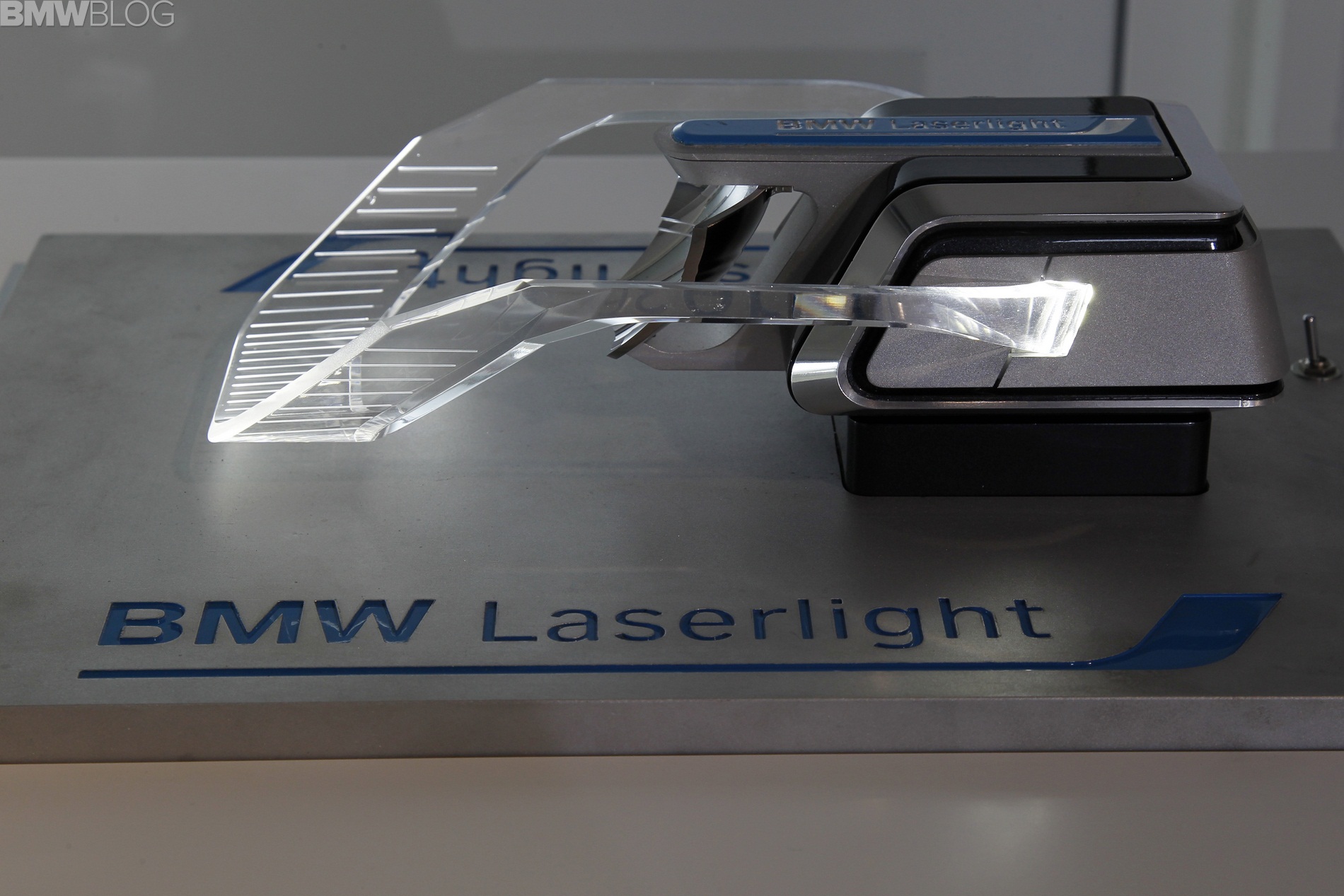

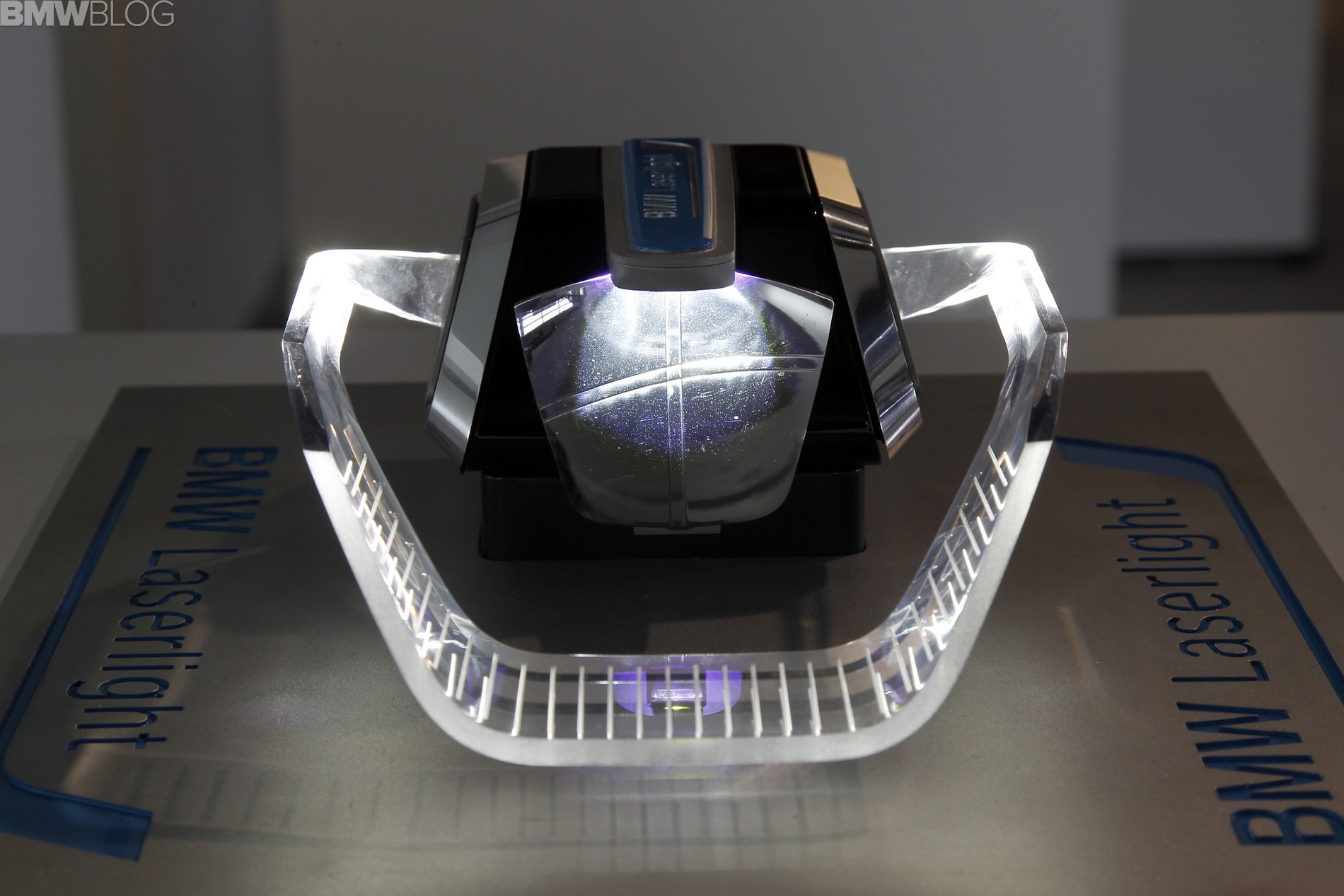

The slim headlights of the BMW i8 team up with the BMW kidney grille to form a horizontal unit emphasising the car’s width. The plug-in hybrid sports car is fitted as standard with powerful and energy-efficient full-LED headlights. In their lower section, the light sources are framed by a U-shaped bar into which are integrated the daytime driving lights, sidelights and direction indicators. The intricately designed rear light clusters also feature the U-shape typical of BMW i cars. All of the lights on the BMW i8 are LEDs as standard.

The BMW i8 is the world’s first series-produced vehicle to be available as an option with innovative laser headlights, which generate a pure-white, extremely bright light that is pleasant to the eye. The light is created through the conversion of the beams emitted by tiny laser diodes by means of a fluorescent phosphor material inside the headlight.

Laser lighting is monochromatic, which means that the light waves all have the same length. They also have a constant phase difference. As a result, laser lighting can produce a near-parallel beam with impressive luminance, which gives it an intensity a thousand times greater than that of conventional LEDs. The beam can also be adjusted extremely precisely. At the same time, the further optimised inherent efficiency of laser lighting means that laser headlights have less than half the energy consumption of even LED headlights, which are already very efficient; laser lighting generates approximately 170 lumens (a photometric unit of light output) per watt, whereas LED lighting generates only around 100 lumens per watt.