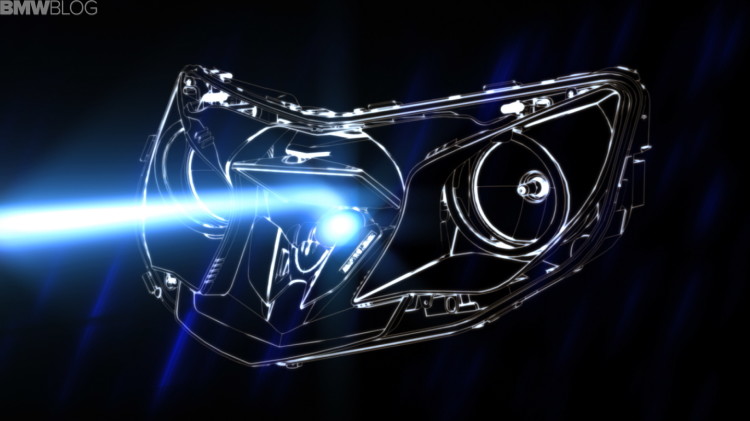

BMW Laserlights will be celebrating their world premiere as of autumn 2014. This highly efficient light source is arriving on our roads in a production car for the first time to provide the high beam in the BMW i8 headlight. Boasting an extremely long, unmatched range, the BMW Laserlights system completely redefines standards for safety, efficiency and design.

The benefits of BMW Laserlights at a glance:

- – BMW Laserlights to feature in a production model for the first time from autumn 2014.

- – Luminous intensity 10 times greater than that of traditional light sources.

- – High beam range of up to 600 metres is double that of conventional headlights.

- – Takes up extremely little space and only needs a very small reflector, resulting in significant weight-saving potential.

- – Excellent efficiency thanks to a 30 per cent reduction in energy consumption.

- – Compact construction opens up new scope for design idiom.

- – Flat design lends itself to optimum aerodynamics.

- – Laser beams are transformed into intense, white light offering maximum safety.

- – Long lasting and highly reliable, even under extreme conditions.

Powerful performance – compact installation – excellent efficiency.

In the laser headlight, the beams of light are bundled together to attain a luminous intensity 10 times greater than conventional light sources, such as halogen, xenon or LED. BMW Laserlights have a visual range of up to 600 metres, twice that of a headlight with conventional light technology.

The light-emitting surface area of a laser diode is one hundred times smaller than that of a conventional LED, which measures one square millimetre. Consequently, a far smaller reflector is needed for laser light. In the case of the BMW i8, a diameter of less than 30 millimetres is sufficient, saving valuable installation space in the vehicle and opening up the potential for significant weight savings, too. By way of comparison: xenon light requires a reflector/lens diameter of around 70 millimetres and halogen light 120 millimetres in order to achieve an adequate light output and range for the respective lighting technology. Another highly beneficial characteristic is the laser light’s excellent efficiency, with a reduction in energy consumption of some 30 per cent. Laser light therefore helps to improve the vehicle’s overall efficiency as well as lowering CO2 emissions. Moreover, the compact construction also opens up new scope in terms of design, while the flat form lends itself to optimum vehicle aerodynamics.

Highly sophisticated technology.

BMW Laserlights take the coherent and monochromatic blue laser beams and transform them into harmless white light. This is done by using special lenses to direct the beams emitted by three high-performance laser diodes onto a fluorescent phosphorous substance inside the laser light source. This fluorescent substance converts the beams into a white light, still with a very high intensity, which the human eye finds particularly pleasant due to its close similarity to daylight. Following conversion of the laser beams, the harmless, dispersed light is projected forward by the headlight unit.

The laser headlight is furthermore equipped with automatic headlight range control to keep the beam of light at a pre-set level, no matter whether the vehicle is driving uphill or downhill, whether it is fully laden or the driver is the sole occupant.

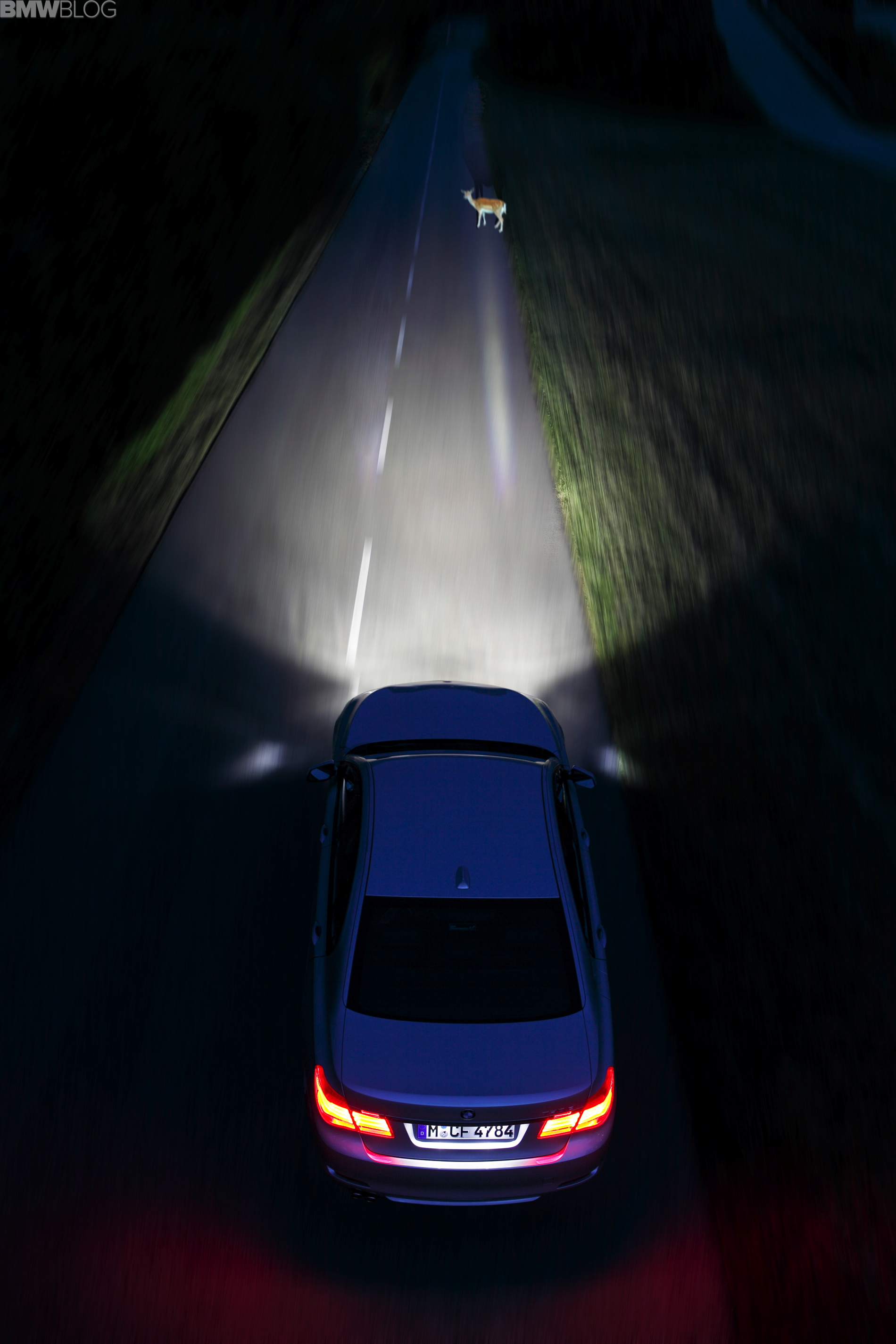

Perfectly reliable under all conditions.

The BMW Laserlights development team was faced with the challenge of adapting the new light technology to the specific and very exacting requirements of automotive applications: from dry polar air to humid tropical regions and from smooth motorways to bumpy country roads, the laser light must continue to work reliably in all climates and over any surface for the vehicle’s entire lifetime. An integral multi-level safety concept provides a sure safeguard against any laser radiation escaping. Meanwhile, the camera-based, digital High Beam Assistant fitted as standard reliably prevents both oncoming traffic and vehicles travelling ahead from being dazzled.

The laser – a safe and powerful light source for the car.

For a number of years now, BMW has been carefully developing and improving the laser headlight to ready it for use in production cars. The laser “boost” light is currently available for the high beam, and supplements the efficient LED high-beam headlight with its range of 300 metres. It was at the 2011 Frankfurt Motor Show that BMW first showcased the laser light in the BMW i8 Concept.

BMW lighting technologies – perfectly in tune with the driver’s needs.

Besides the new optional laser light with its tremendous brightness and range, the front headlight units on the BMW i8 employ LED technology for the low beam, side lights, daytime running light and turn signals. The various technologies work together to produce an ideal solution for each specific lighting function that is requested. The upshot is perfect lighting, an excellent view and maximum safety combined with high efficiency at all times.

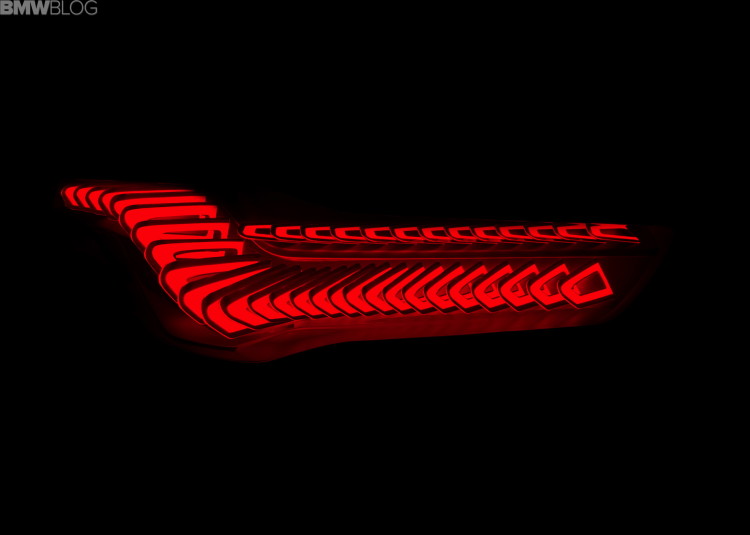

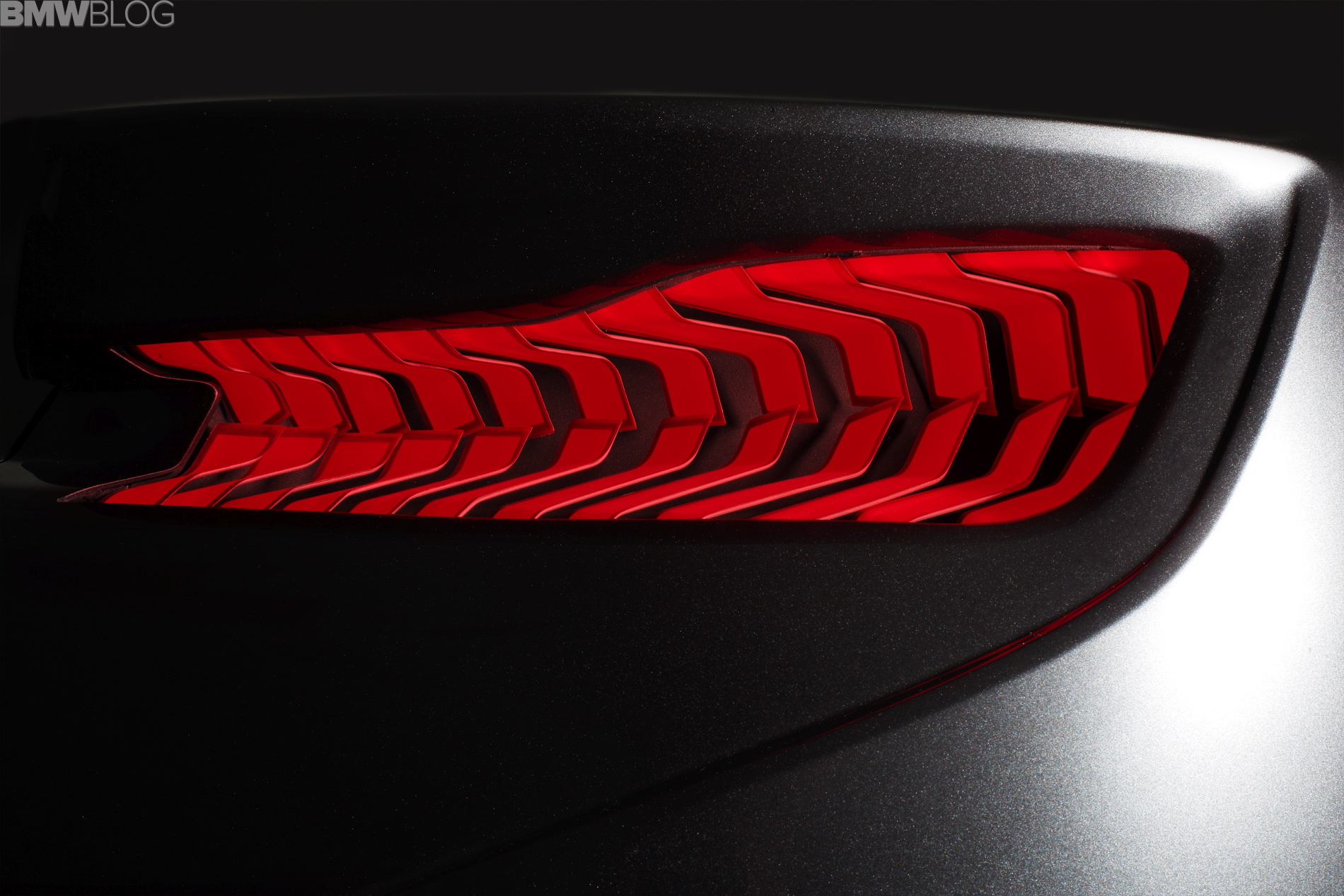

BMW innovation in light design: BMW Organic Light – OLEDs open up new avenues for styling.

Organic light-emitting diodes, or OLEDs, are innovative, efficient and sustainable light sources that BMW will be fitting in its vehicles in the near future under the name BMW Organic Light. In OLEDs, the light is emitted by wafer-thin semi-conductive layers made from organic materials. OLEDs work very efficiently by design and generate very little heat as a result. BMW Organic Light thus helps to further reduce CO2 emissions. Rather than being emitted in the form of points, the light generated by OLEDs shines out over a relatively large area compared to LEDs and is extremely homogeneous in appearance. Consequently, OLEDs are suitable for use in exterior lighting functions that are primarily designed for being seen. Rather than replacing conventional LEDs, however, OLEDs will complement them. Initial applications in production cars could see OLEDs taking over the function of the tail light as part of a so-called hybrid light, while brake lights and turn signals continue to employ LEDs. In the medium term, the efficiency and luminance of OLEDs will increase to the extent that other lighting functions can also be carried out by organic LEDs. Inside the vehicle, meanwhile, BMW Organic Light can be used to create pleasant and stylish lighting effects. The fact that they can be shaped in so many different ways means that organic light-emitting diodes offer designers brand new possibilities for styling.

150 times thinner than a human hair.

The pleasant light produced by organic light-emitting diodes is given off over their entire surface with an extremely homogeneous effect. This characteristic is down to their special design. In contrast to conventional LEDs, where the light is produced in semiconductor crystals, the light in OLEDs is generated in extremely thin semi-conductive layers made from organic materials, mostly polymers. Together with the conducting layers, these are hermetically sealed between two thin glass plates or plastic films. The entire set of active, light emitting layers measures a mere 400 nanometres or so in height (one nanometre is equal to one millionth of a millimetre). That is some 150 times thinner than a human hair, which measures around 0.06 millimetres across on average. The complete component is about 0.8 to 1.5 millimetres in height overall.

Due to the very low power consumption and weight of OLEDs, BMW Organic Light also helps to reduce the fuel consumption of vehicles with combustion engines, extend the range of electric cars and, as a result, cut CO2 pollution.

The sustainability of this technology represents a further major benefit. The manufacture of organic light-emitting diodes does not involve any costly and scarce raw materials such as “rare earths”. What’s more, the quantity of organic substances and metals used is so low that it will be possible to simply dispose of OLEDs in the waste glass container at the end of their service life.

Huge potential for automotive design.

The OLED technology in BMW Organic Light and its possible uses open up tremendous potential for automotive design. When they are first launched, the organic LEDs will be two-dimensional in appearance with a luminous area that can be shaped as desired, and will look like a reflective surface when switched off. As development progresses, flexible OLEDs that are also transparent will be brought out. Three-dimensional OLEDs with freely definable shapes are a likely prospect in the medium term. The fact that OLEDs are formable and require neither reflectors nor lenses paves the way for a whole new range of uses that are not feasible at the current time.

Dynamic and effective light displays.

Organic light-emitting diodes can be used for fulfilling static exterior lighting functions or illuminating the vehicle’s interior. BMW Organic Light is continuously dimmable in the same way as conventional LEDs. What’s more, the luminous area of an OLED can be subdivided into separate, individually designed segments and controlled separately as well, allowing for the creation of dynamic and effective light displays.

Designed to last.

BMW Organic Light is optimised to satisfy the most stringent requirements in terms of reliability and durability. It is designed to withstand changing environmental conditions and last for a vehicle’s entire lifetime. The virtually maintenance-free operation of BMW Organic Light is another major bonus.

BMW Selective Beam from BMW ConnectedDrive: Permanent anti-dazzle high beam for a clearer view in the dark.

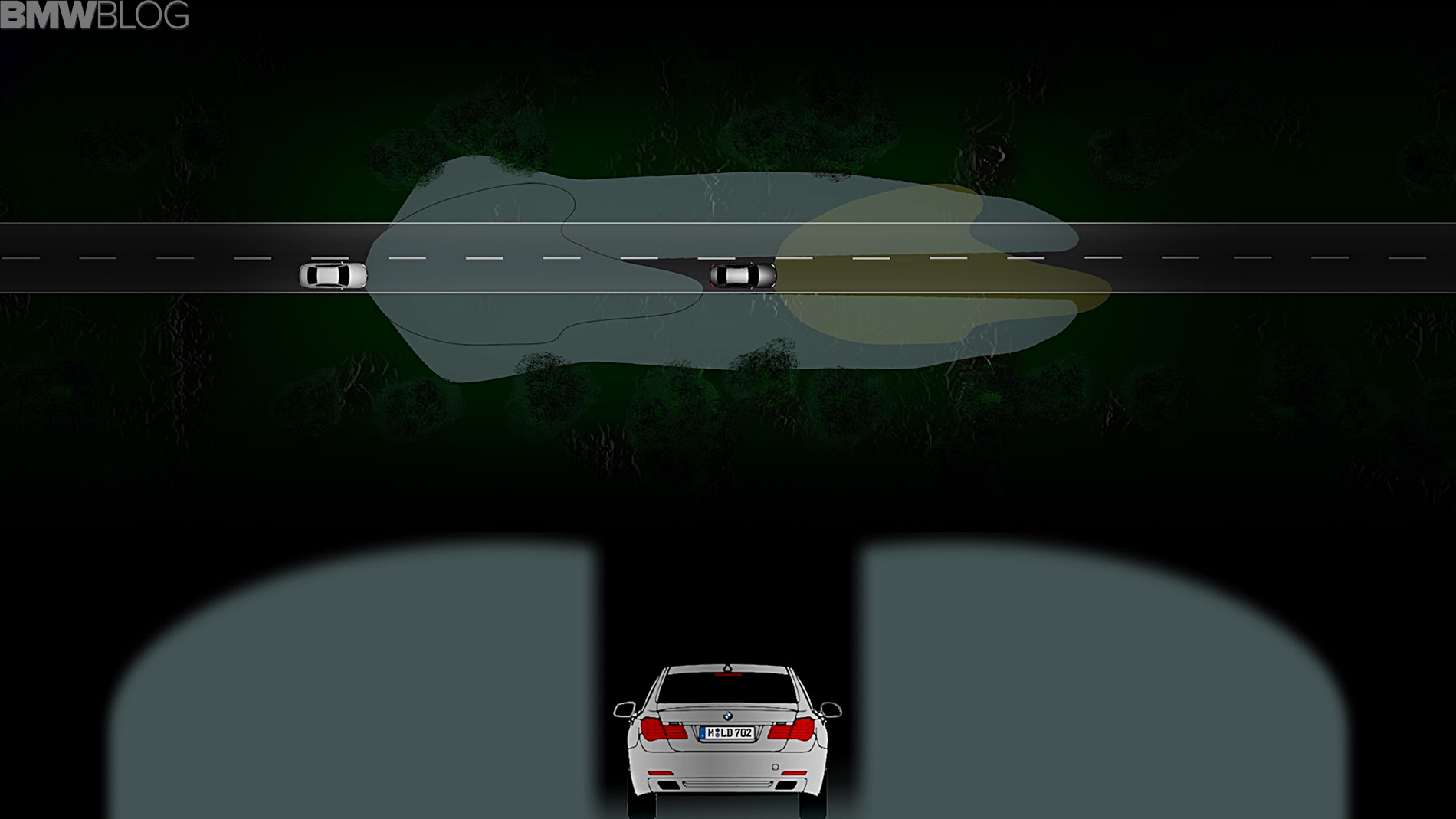

BMW Selective Beam from BMW ConnectedDrive has been in use since 2012 and offers supreme safety and an optimum visual range. It allows the high beam to be left on all the time while driving by using a masking function to shield other road users from the beam of light and thereby reliably prevent dazzling. Deploying BMW Selective Beam greatly increases usage of the high-beam headlights and therefore visibility after dark.

BMW Selective Beam enhances driving safety.

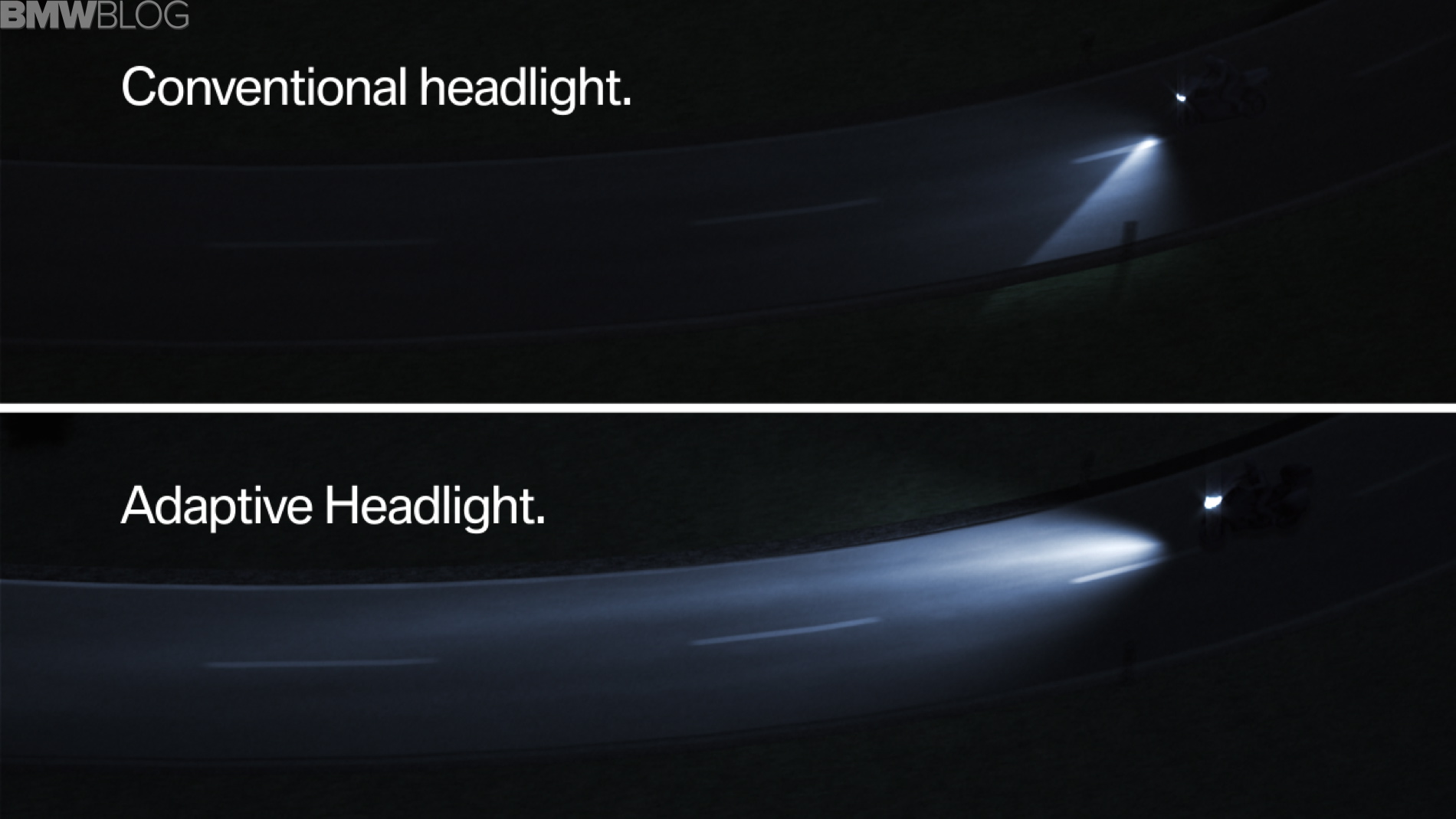

Several studies (e.g. from Drivingvisionnews.com) have revealed that many motorists use the high beam only very seldom or not at all, partly for convenience sake. This is where BMW Selective Beam comes to the driver’s assistance by dispensing with the need to keep switching between high and low beam. To this end, a camera in the base of the rear-view mirror monitors the area in front of the vehicle. The image data is relayed to a control unit that then masks out other vehicles from the high beam’s cone of light with split- second speed. In the case of xenon and LED headlights, this is done using a special optical lens or reflector system designed to produce a high beam with no dazzling. Once the road is clear again, the system automatically switches to full high beam again. This results in more time spent driving with the high beam switched on and therefore greater driving safety thanks to the clearer view and the ability to see further down the road.

See further, react earlier, feel more relaxed at the wheel.

When driving without the high beam switched on, the driver loses a great deal of visual range, as a comparison of the respective range of low-beam and high-beam headlights clearly shows: low beam illuminates the road ahead for a distance of just 70 to 80 metres, whereas the high-beam light extends over a distance of approx. 300 metres. When travelling at a speed of 100 km/h (62 mph) the vehicle’s braking distance alone in the event of an emergency stop is approx. 40 metres. Once the driver’s reaction time is factored in, the resulting total stopping distance is at least 80 metres. While in daylight drivers are able to view the road ahead for as far as the eye can see – which can be as much as five kilometres (approx. three miles) on a straight road – in the dark, the visual range is limited to the illuminated stretch of road. If an obstacle suddenly appears in the headlights’ beams, the available braking distance is often insufficient to bring the vehicle to a stop in time. Keeping the main beam switched on permanently when driving at night to benefit from its far greater range is therefore the most effective way of avoiding hazardous situations.

Precise masking of other road users.

One key benefit of BMW Selective Beam lies in its ability to shield other road users from the high beam’s cone of light with great precision. Anti-dazzle high-beam headlights are designed to distribute light in such a way that oncoming traffic or road users ahead are masked out with complete reliability and with low light scattering. The swivel motors that move the high beam operate to an accuracy of 0.1 degrees. Only the smallest area required is masked, thereby minimising the loss of light intensity. As far as the driver is concerned, this means that the road ahead is lit up to the best possible effect at all times.

In contrast to BMW Selective Beam with its system of minimal masking, some other systems completely deactivate some of the LEDs used for the high beam in order to prevent oncoming traffic or vehicles ahead from being dazzled. This is accompanied, however, by a significant loss of both brightness and illumination width, thus limiting the high beam’s lighting power to a far greater degree.

BMW Motorrad with innovative lighting concepts: Enhanced safety and performance, appealing design.

BMW Motorrad has been shaping the technical development of motorcycles for more than 90 years, continuously coming up with new, innovative technologies. These range from the first hydraulically attenuated telescopic fork in 1934 and the introduction of ABS in 1988 to the semi-active chassis of 2012, to name but three examples from a series of key developments. Now, as then, BMW Motorrad has a clearly defined goal in mind: to make motorcycles even more powerful, attractive and, above all, safer. In this,

BMW Motorrad also focuses on lighting for motorcycles and has also consistently pressed forward with developments in this area for decades.

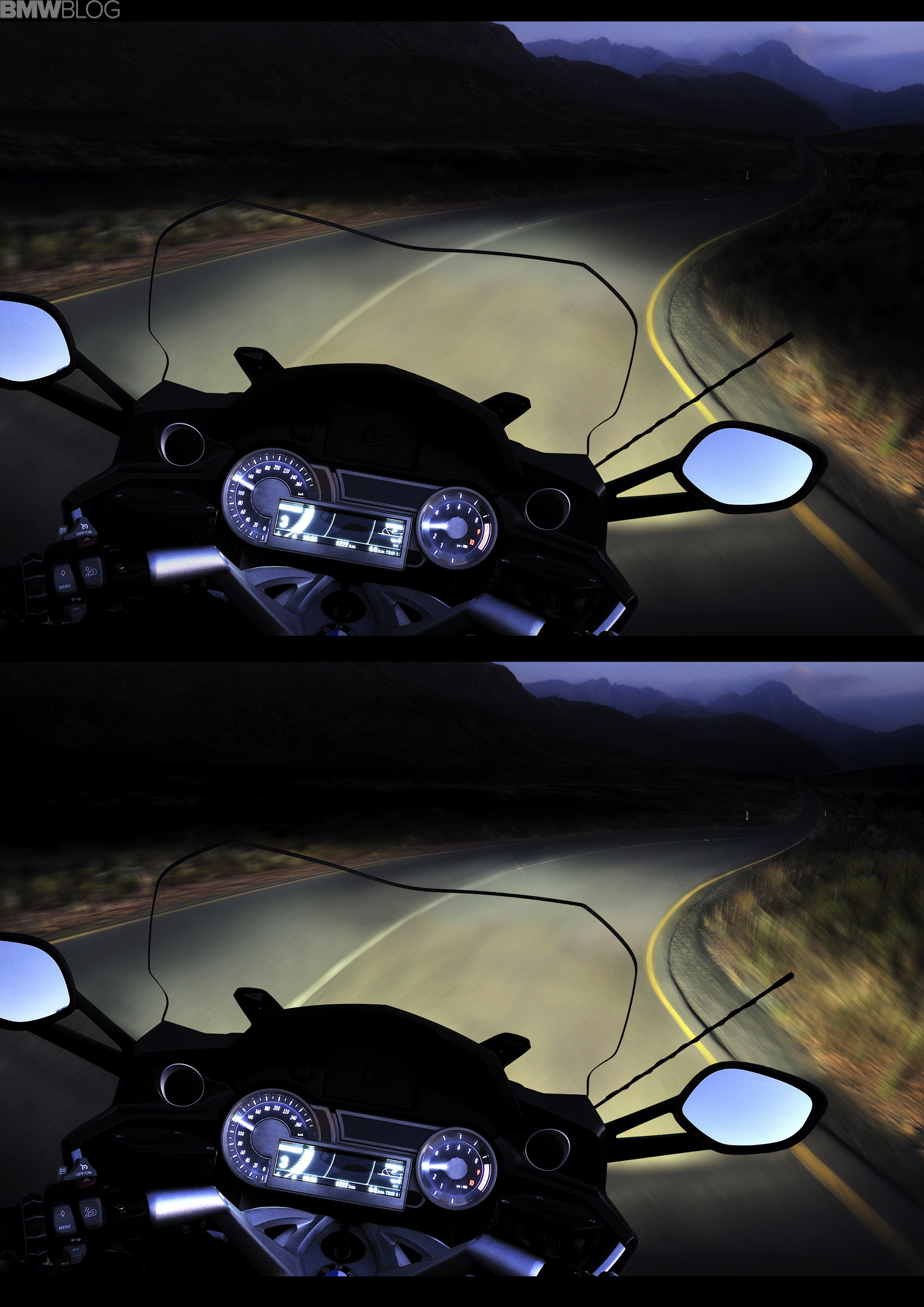

2010 – BMW K 1600 GT and GTL: the first motorcycles in the world with an adaptive xenon headlight for even greater safety at night. With the new BMW K 1600GT and GTL touring bikes, the first ever Adaptive Headlight is introduced in autumn 2010 as a factory option to supplement the standard xenon headlamp. In addition to standard pitch compensation, the light of the main headlamp is also balanced in relation to the banking angle.

The low beam unit fitted as standard in the main headlamp consists of a centrally positioned, movable xenon project module with reflector mirror. Ride height sensors at the front and rear axle provide data for permanent headlamp levelling. Due to the pitch compensation function, the headlamp also sheds light in the optimum set area when the motorcycle is travelling straight ahead, regardless of riding and load conditions.

The optional Adaptive Headlight also features a servomotor, which turns the standard static reflector mirror into a swivel mirror. In relation to the banking angle, the mirror is then turned on an axis and compensates for the roll angle of the vehicle. In addition to pitch compensation, the low beam light of the main headlamp is also balanced in relation to the banking angle. The two movements are superimposed, resulting in light being directed into the bend. This produces significantly improved illumination of the road when cornering and therefore an enormous increase in active riding safety.

2011 – C 600 Sport and C 650 GT: LED lights, optional LED daytime running light and way home function.

The maxi scooters C 600 Sport and C 650 GT are already fitted as standard with a rear light and LED stowage space lighting. The LED technology is characterised in particular by high fail safety, long service life, high luminous efficiency, and low power consumption.

The front lighting on the C 600 Sport consists of one headlight each for low and high beams and two side lights or stand lights. The C 650 GT likewise presents two headlights, but the side light and optional daytime running light take the form of three LED light elements arranged at the centre. Both the side lights and the stowage space lighting come with a so-called way home function, i.e. they continue to light after the vehicle has been parked. The rider can adjust the timing of this function to individual needs.

Whereas LED turn indicators are offered as optional equipment ex works for the C 600 Sport, this feature is fitted as standard on the C 650 GT. In addition, both models can make use of the highline package (optional equipment ex works) that provides the LED daytime running light, a rare treat for that extra safety on the scooter market.

2012 – R 1200 GS: The first motorcycle in the world with LED main headlight including integrated daytime running light for even greater safety when riding during the day and at night.

Even in its standard trim, the new R 1200 GS has a main headlight with optimised light efficiency. In order to be seen even better during the day, BMW Motorrad also offers a daytime running light as an ex works option. For excellent road illumination and therefore even greater safety both day and night, an LED main headlight with integrated daytime running light is fitted in a motorcycle for the first time ever. It comprises innovative LED technology with a sophisticated cooling and decondensation concept.

The light unit consists of two LED units each for low and high beam, as well as four additional LED units for the daytime running light and side light. These are mounted on a central heat sink made of die-cast aluminium.

Behind the heat sink is an axial fan. An additional air ducting element directs the warm air onto the glass panel, thereby generating air circulation inside the headlight. This air circulation ensures decondensation of the headlight, also contributing actively to the de-icing of the lens in winter.

2014 – BMW Organic Light: OLEDs (organic light emitting diodes) open up a range of new opportunities for lighting on BMW motorcycles.

Although BMW Motorrad has already made significant progress with the introduction of LED technology for main headlights, daytime running lights, rear lights and indicators in comparison with conventional incandescent lighting technology, developments in the area of LEDs are still ongoing.

With the development of organic LEDs (OLEDs), it has proven possible to create a thin-layered component from organic semiconductor material. Compared to the inorganic material already used in LEDs in standard production vehicles, the application of OLEDS in BMW Organic Light promises a range of benefits. Because of the design as a thin-layered element, for example, it is possible to produce very thin, flexible displays for smartphones or even lighting units for motor vehicles.

The inorganic LEDs we currently encounter in many application areas operate with a semiconductor crystal embedded in a conical recess that acts as a reflector. The luminous intensity achieved in this way is not constant across the entire angle of radiation, however. This means that the light from an LED lamp always seems less bright to the human eye the more it is seen from the side. This is why current LED lamp units in cars always have optical aids like highly developed reflectors aimed at reducing this effect and achieving a relatively homogeneous luminous intensity with the greatest possible radiant angle and viewing angle, thus ensuring the “strength” of the light to the human eye.

On the other hand, BMW Organic Light permits a lamp unit to be created whose luminous intensity is almost constant across the entire radiant angle, coming very close in physical terms to the theoretical characteristics of a so- called ideal Lambert radiator. This makes it possible to dispense with complex optical aids such as reflectors, for example, and together with the thin-layered, slim-line design of the OLEDs, whose backing material can be used directly as an electrical conductor, opens up entirely new design options for the development of light units for BMW motorcycles.

At present, the luminous density of the OLEDs is still insufficient and more development work is needed. While this is adequate at present for a rear light, lighting elements like the brake light or indicator need reinforcing. This is achieved through the use of additional conventional LEDs. However, these hybrid solutions permit a new visual language. The staggered arrangement of the almost completely freely configurable OLED elements creates a highly three-dimensional lighting effect that viewers find very attractive. On the other hand, the familiar conventional LEDs ensure sufficient luminous density.

While such hybrid solutions involving OLEDs and LEDs could make their way into BMW standard motorcycles within the next two or three years, it will take a few more years yet to develop brake lights, indicators or even headlights that use OLED technology alone. Assuming that their luminous density is significantly improved, OLEDs will possibly lead to completely redesigned, more attractive lamp units for BMW motorcycles. However, as well as greater visual appeal, BMW Motorrad is also concerned with achieving maximum performance and safety in its motorcycles, thus also maximising safe riding fun.

BMW lighting technology: Pioneering developments since 1971.

At BMW, innovative technology is never an end in itself, but always supports the brand’s mission to provide “Sheer Driving Pleasure”. Lighting technology, too, as a key safety feature, has a long tradition of continuous evolution and innovation at BMW. That’s because seeing and being seen is crucial to safe driving at night or in conditions of poor visibility.

1971: Halogen lighting replaces the previous bilux two-filament (high- beam/low-beam) bulbs. With a separate halogen bulb or dual-filament H4 bulb for high beam only, halogen lighting provides significantly enhanced night- driving vision for BMW drivers.

1974: The now typical BMW twin round headlights, with separate lights for low beam and high beam, make their debut in the first BMW 5 Series (E12).

1991: BMW equips its first production model with optional xenon headlights. This technology provides even better illumination than halogen headlights and also has a longer life. In xenon headlights, a high-voltage ignition pulse is applied to produce an arc of light in a bulb filled with the inert gas xenon.

2001: “Corona rings” surrounding the twin round headlights make their debut. For the time being they function only as parking lights / side lights. Today, the corona rings are a distinctive hallmark of all BMW core brand models.

2003: BMW introduces its first models with Adaptive Headlights and cornering lights, which provide an earlier view into bends and side roads. This system provides greatly improved visibility and safety, whether going round bends on the open road or turning into a side road in the city.

2005: The corona rings take on an additional function as daytime running lights. The brightly illuminated running lights make the vehicle more visible in daytime driving as well. A further new lighting function introduced the same year, the camera-based High Beam Assistant, switches automatically between low and high beam.

2007: A new version of the Adaptive Headlights and cornering lights is introduced. Now the headlights not only follow the direction of the road, they also feature variable light distribution, which alters the illumination depending on driving conditions. At the same time, the headlight beam is now raised at higher speeds and lowered at slower speeds. This results in a wider beam when driving in the city. The new system also incorporates adaptive range control, which takes into account ups and downs in the road. The headlight beam is lowered when going up a rise in the road and raised when heading into a dip, ensuring optimal road illumination at all times.

2009: The corona ring daytime running lights are upgraded to an LED setup, which is not only even brighter but also consumes significantly less energy.

2011: BMW introduces LED headlights with three-dimensional daytime running light rings, which add a futuristic dimension to the characteristic BMW four-headlamp face. Because its temperature is similar to that of daylight, LED light produces a very bright beam, enabling traffic signs to be seen earlier and more clearly.

2012: BMW Selective Beam is introduced. Basically, this system is a permanently activated high beam which is adjusted automatically so as not to dazzle other road users. The BMW anti-dazzle High Beam Assistant is available for both xenon and LED headlights. With the new BMW 7 Series, BMW makes motoring history by developing both the low beam and the daytime running light from a shared optical unit as an illuminated design icon. The idea of extending this hallmark feature to the low beam lends the BMW twin round headlamps a far more striking recognition impact at night.

2014: With its innovative BMW Laserlights, BMW will become the first manufacturer in the world to supply laser headlights as optional equipment for a production vehicle – the BMW i8. Blue laser light acts on a phosphor material inside the BMW Laserlights to produce a white light similar in intensity to sunlight. This “laser boost” feature provides a high-beam range of up to 600 metres.