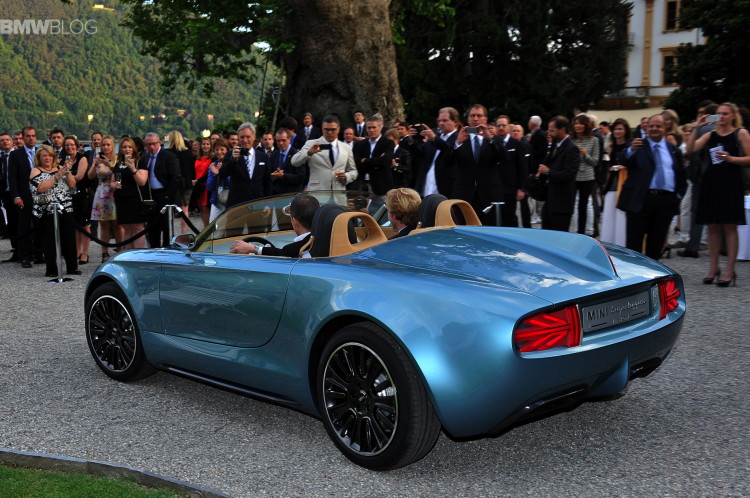

In light of an Automotive News Europe interview with Peter Schwarzenbauer, MINI’s chief, I’ve decided to promote myself from non-influential scribbler to Manager of Product Development – BMW. This will allow me to insert myself into the production path of taking the gorgeous MINI Superleggera Vision concept from dream to reality – and I intend to do this using existing BMW processes and facilities.

Upon meeting with the various marketing, styling, and engineering personnel our first order of business is to determine sales numbers. I suspect the marketing folks will say 3,000 to 4,000 a year at approximately 40K USD. At which point engineering will say, “then we can’t do anything bespoke to this model – you’ll need to use existing drivetrain and suspension components”. And then the styling folks will say, “but you can’t harm a hair on the head of the concept – the concept’s lines are perfect – they have to carry over to production as is”.

Heck of a dilemma, but not really. I’ll say, “It can be done, on budget, at the volumes required, and we can keep the styling intact.” So how is that possible? Take the three cylinder engine and suspension from the i8 on an aluminum chassis. Reduce the wheelbase (since it doesn’t need a battery pack). Radiator up front and plumbing down the center console. I’d then have a CFRP passenger shell, again, like the i8. That will allow the concepts lines to be duplicated in thermoplastic (like the i3 and i8). Heck you can even keep the cool dorsal fin of the concept. Then have it slotted into the production sequence in Leipzig.

This is doable. And it makes sense. You end up with a 200 HP 2200 lb MINI. It’ll scoot and look like the business doing it. Oh and widen the track, insert the four cylinder and change up the body panels – they’re thermoplastic so no big problem – and slap a roundel and a Z2 badge on it . .