Dutch King Willem-Alexander giving the ceremonial go-ahead for the MINI production on the occasion of the reopening of VDL Nedcar’s Born plant.

MINI production volume at VDL Nedcar to reach a five-digit range as early as this year.

Born/Munich. The new MINI Hatch, which celebrated its production start at the BMW Group’s plant in Oxford in November 2013, will also be built at contract manufacturer VDL Nedcar in Born/Netherlands from now on. Dutch King Willem-Alexander attended an official function on the occasion of the reopening of the plant in Born, giving the ceremonial go-ahead for the MINI production at VDL Nedcar that let the first vehicle roll off the assembly line. Further guests included the German Ambassador, Franz Josef Kremp; the Netherland’s Secretary of Economic Affairs, Henk Kamp; the CEO of VDL Groep, Wim van der Leegte; Dr. Andreas Wendt, Director of BMW Group Plant Regensburg – the partner plant of VDL Nedcar in Born; and Dr. Johann Wieland, Head of Indirect Purchasing, BMW Group.

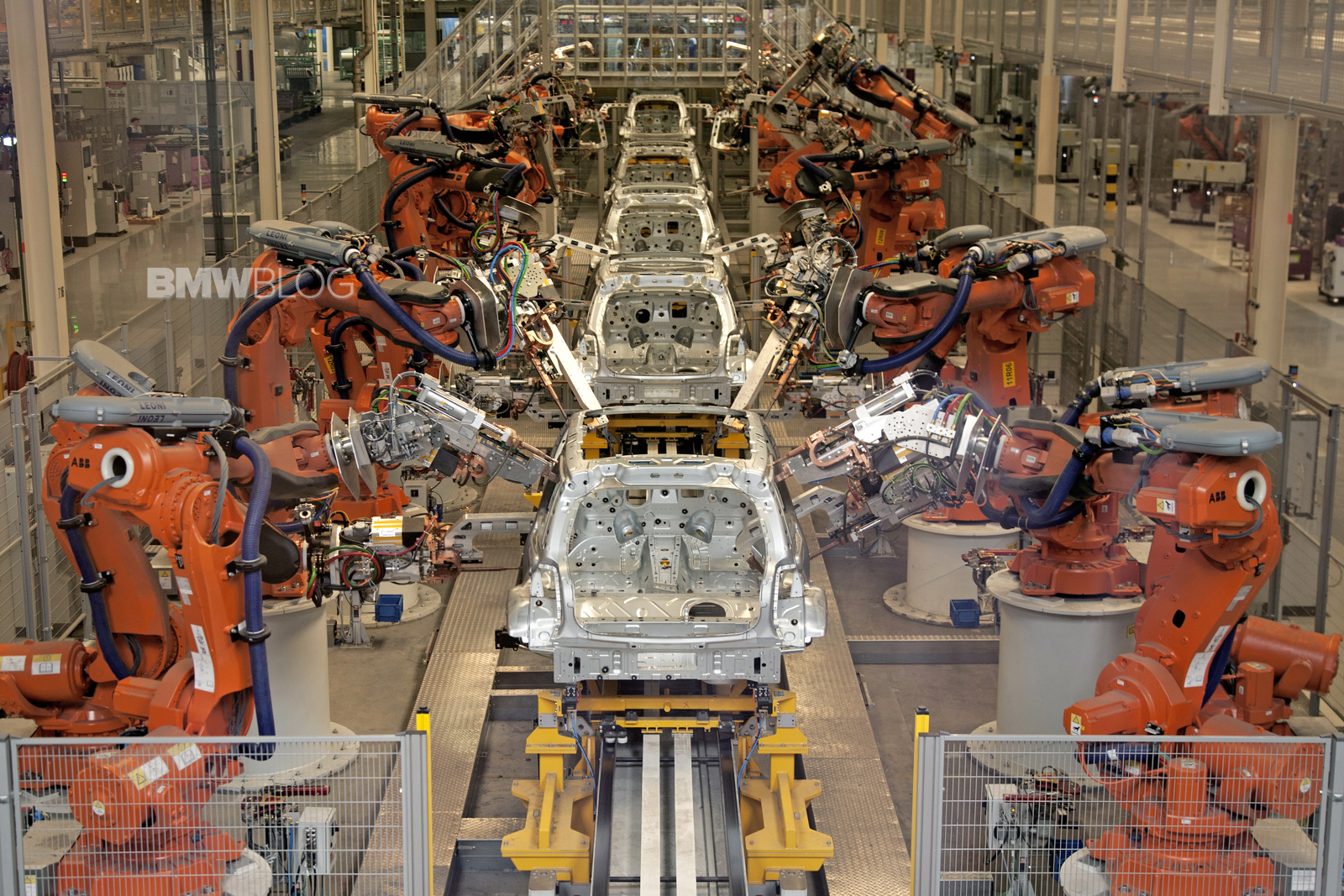

This move makes MINI the only automotive manufacturer that has series production vehicles built through a contract production in the Netherlands. The BMW Group stands to benefit from the favorable location of the VDL Nedcar site in terms of logistics and its proximity to the UK MINI production network with its locations in Oxford, Swindon and Hams Hall. At the same time, the BMW Group is stepping up its presence in the Netherlands significantly, making the region an integral part of the MINI success story.

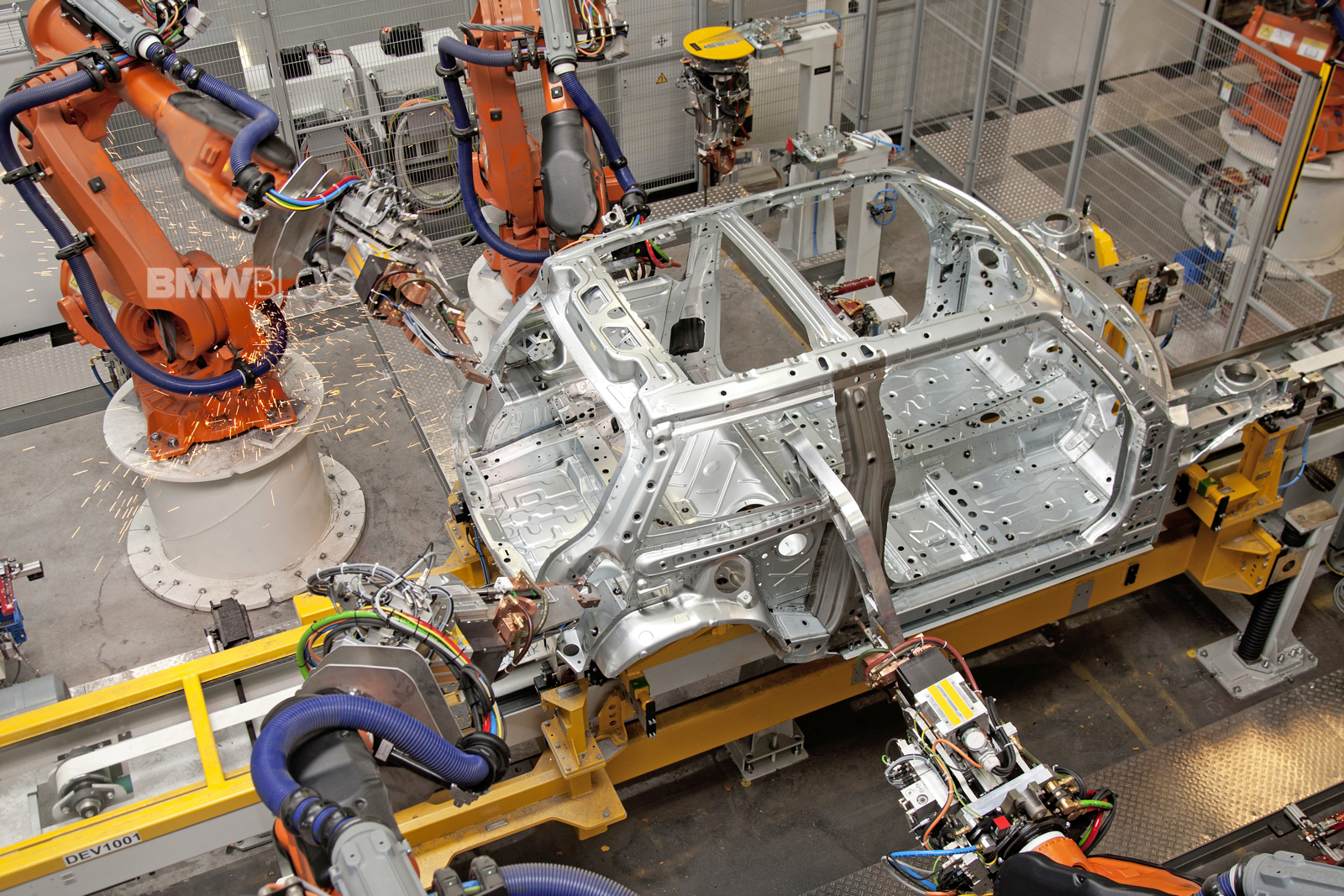

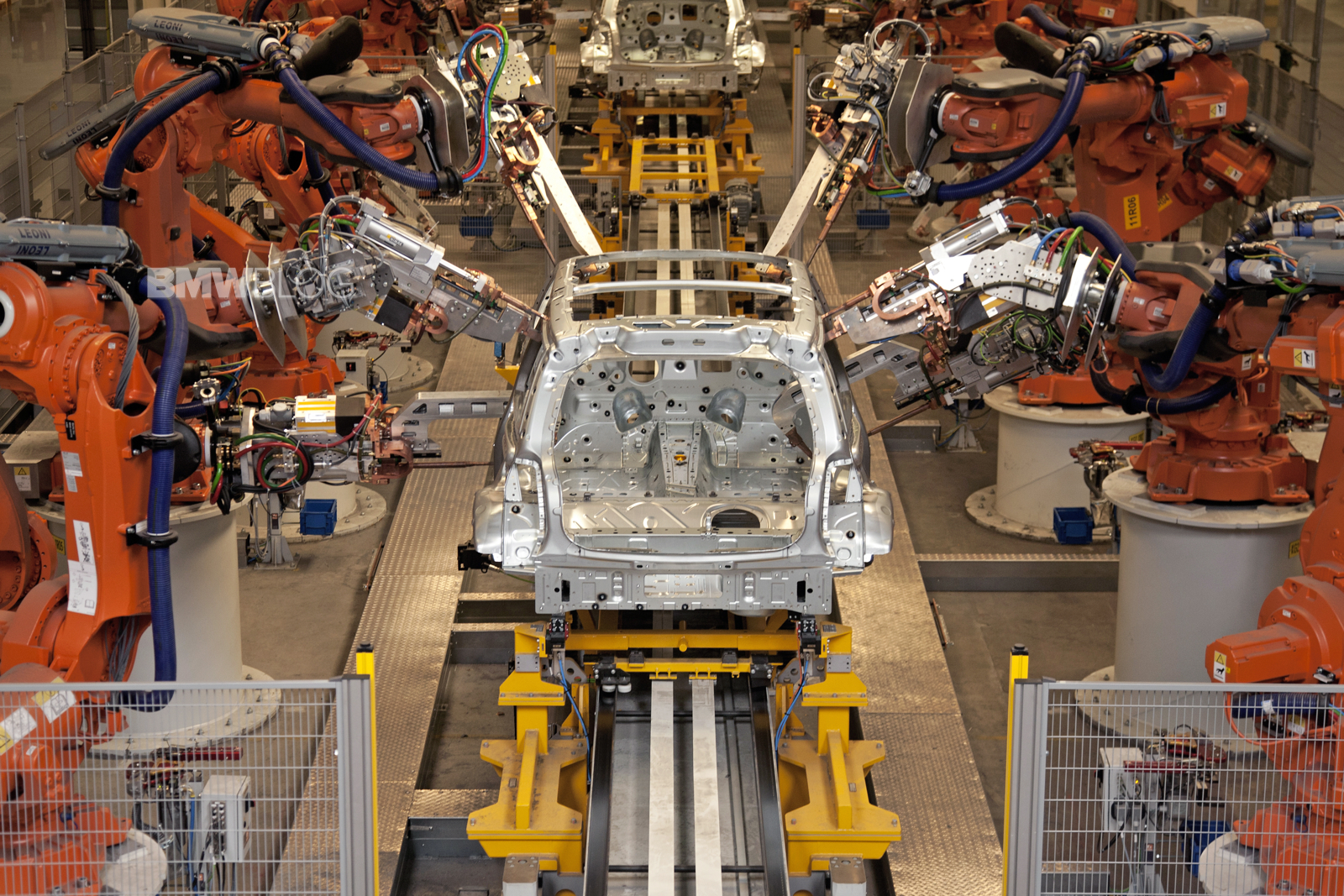

A workforce of around 2,000 people will be responsible for building the new MINI from summer 2014. This year, the MINI production volume at VDL Nedcar is anticipated to already reach a five-digit range. The same demanding quality standards apply to MINI production in Oxford and Born. In order to ensure these quality standards, VDL Nedcar staff received in-depth training on the BMW Group production system at the BMW plants in Leipzig, Oxford and Regensburg.

Global growth strategy – Expansion of production capacities.

As another important step in the implementation of the global growth strategy, the BMW Group is currently expanding its overall production capacity. As the MINI brand is showing substantial growth, the BMW Group needs additional, external production capacity on top of the capacity of the MINI plant in Oxford which stands at about 260,000 units per year in the medium term. Splitting production of the new MINI Hatch between Oxford and the contract manufacturer VDL Nedcar will give the BMW Group’s global production network with its 29 production sites in 14 countries on four continents greater flexibility for other models. At the same time, the UK production triangle is and will remain the heart of MINI production. “Contract production is a vital flexibility tool for us, and our experience gathered over the past ten years has been nothing but positive. Splitting production of the new MINI Hatch between Oxford and Born will give our global production network additional leeway,” stated Dr. Andreas Wendt, Director of the BMW Group’s Regensburg plant, the partner plant of VDL Nedcar in Born. “We appreciate the reliable, open and trustful cooperation with our Dutch partner. VDL Nedcar has many years of experience in producing high quality vehicles.”

In 2013, the BMW Group produced a total of 303,177 MINI vehicles. Plant Oxford produced 175,986 MINI Hatch, Convertible, Clubman, Clubvan, Roadster and Coupé models. An additional 125,559 MINI Countryman and MINI Paceman models were built by the contract manufacturer MSF in Graz/Austria, plus additional 1,632 units in other plants. Since the relaunch of the brand in 2001 until the end of 2013, nearly 2.8 million MINI vehicles have been produced.