In 2004, BMW took on the America’s Cup challenge in partnership with the BMW ORACLE Racing team. Two aviation and aerospace engineers from the Bavarian automobile constructor were dispatched to the design team at the Challenger of Record, tasked with using BMW technology transfer to win the most prestigious sailing trophy in the world. In 2010, it was mission accomplished, as BMW ORACLE Racing wins the 33rd America’s Cup in Valencia. That same year marks the founding of the BMW i brand.

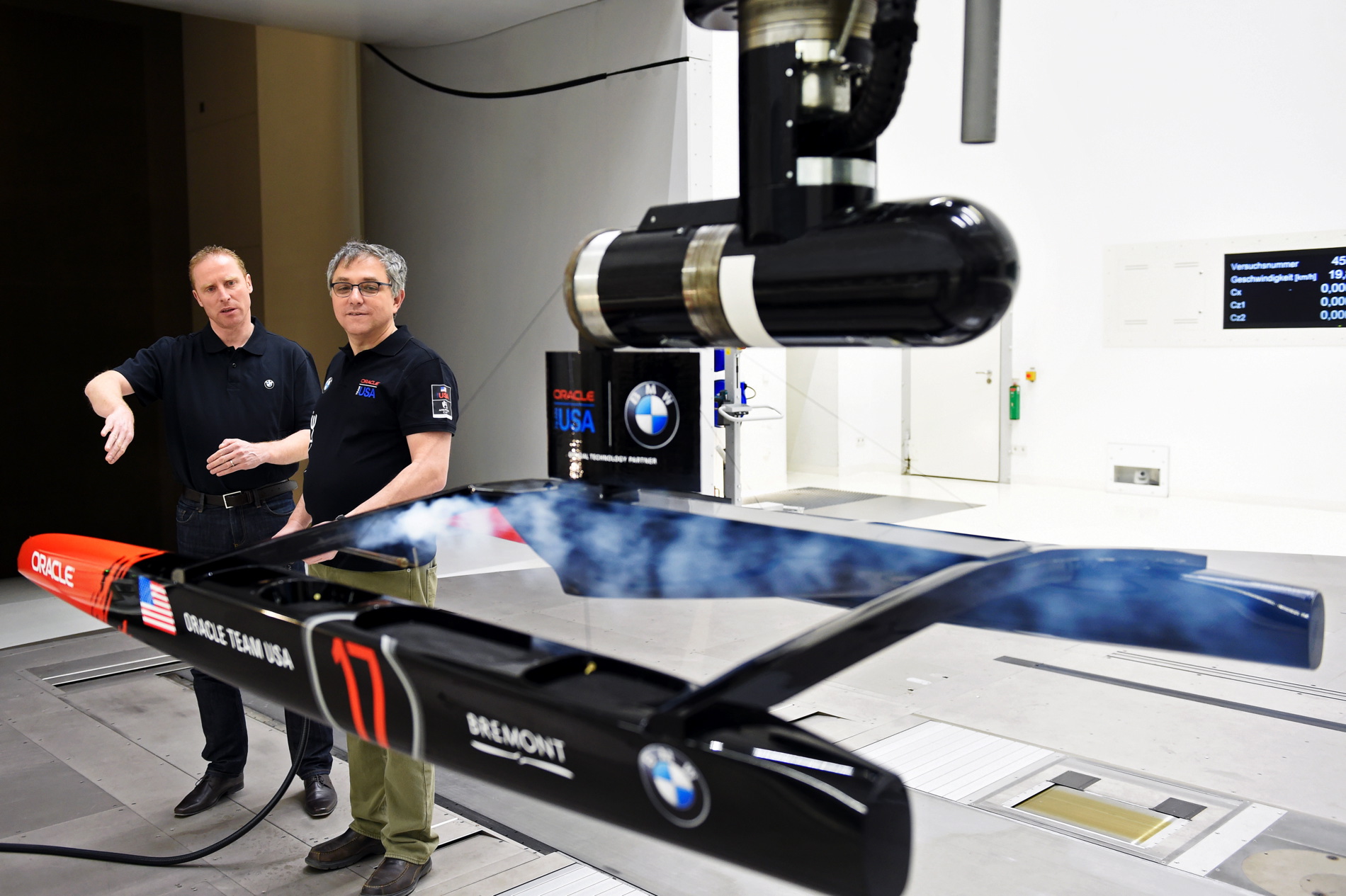

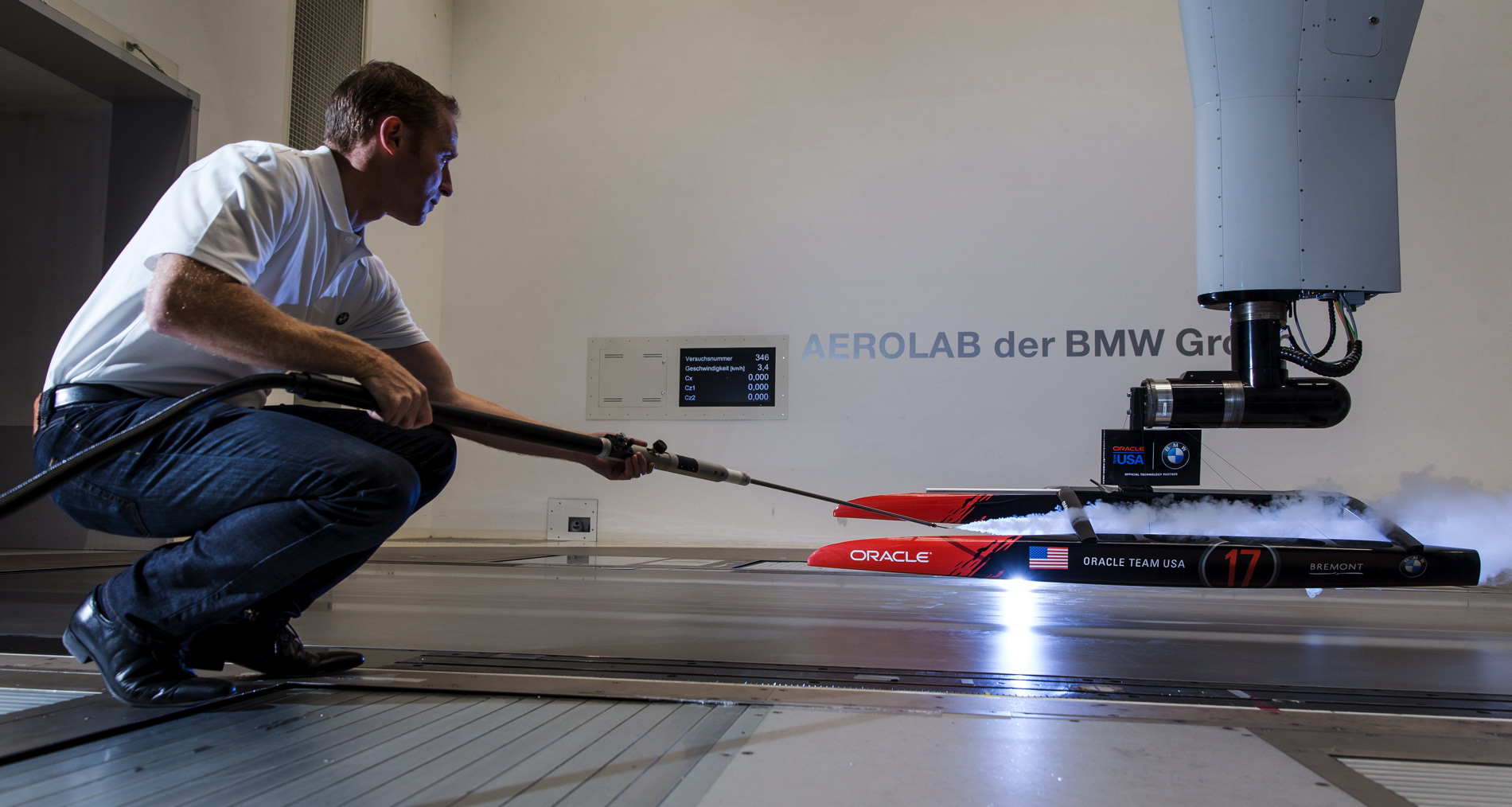

The expertise of BMW engineers was much in demand at the BMW ORACLE Racing Team. Lightweight design specialists Thomas Hahn and Christoph Erbelding were responsible for structural analysis and optimization methods. Their key task was to achieve the maximum degree of structural optimization in the carbon hull of the yachts for the 32nd America’s Cup. The IACC rule at this time specified a maximum weight. As the speed of the keel boats was dependent on the righting moment of the keel /bulb that had to be as heavy as possible, the hull had to be as light as possible – but still able to withstand great force. The rig pressed against the hull with a compression force of 65 tonnes.

“We applied our analysis and optimization methods from the automobile industry to successfully influence the layout – meaning the number and positioning of various carbon layers – during construction of the boats. The BMW ORACLE TEAM yacht was one of the lightest to compete in the 32nd America’s Cup,” says Hahn. In addition to the lightweight design expertise, BMW also supported technology transfer in production for the America’s Cup project: The keel fin was produced in the BMW plant in Eisenach.

The BMW engineers also realized that they would hardly use prototypes, a normal part of the automobile development process, for the America’s Cup project. The results of the design team’s computer work have to function in the race. Engineers must deliver pioneering design, at high speed.

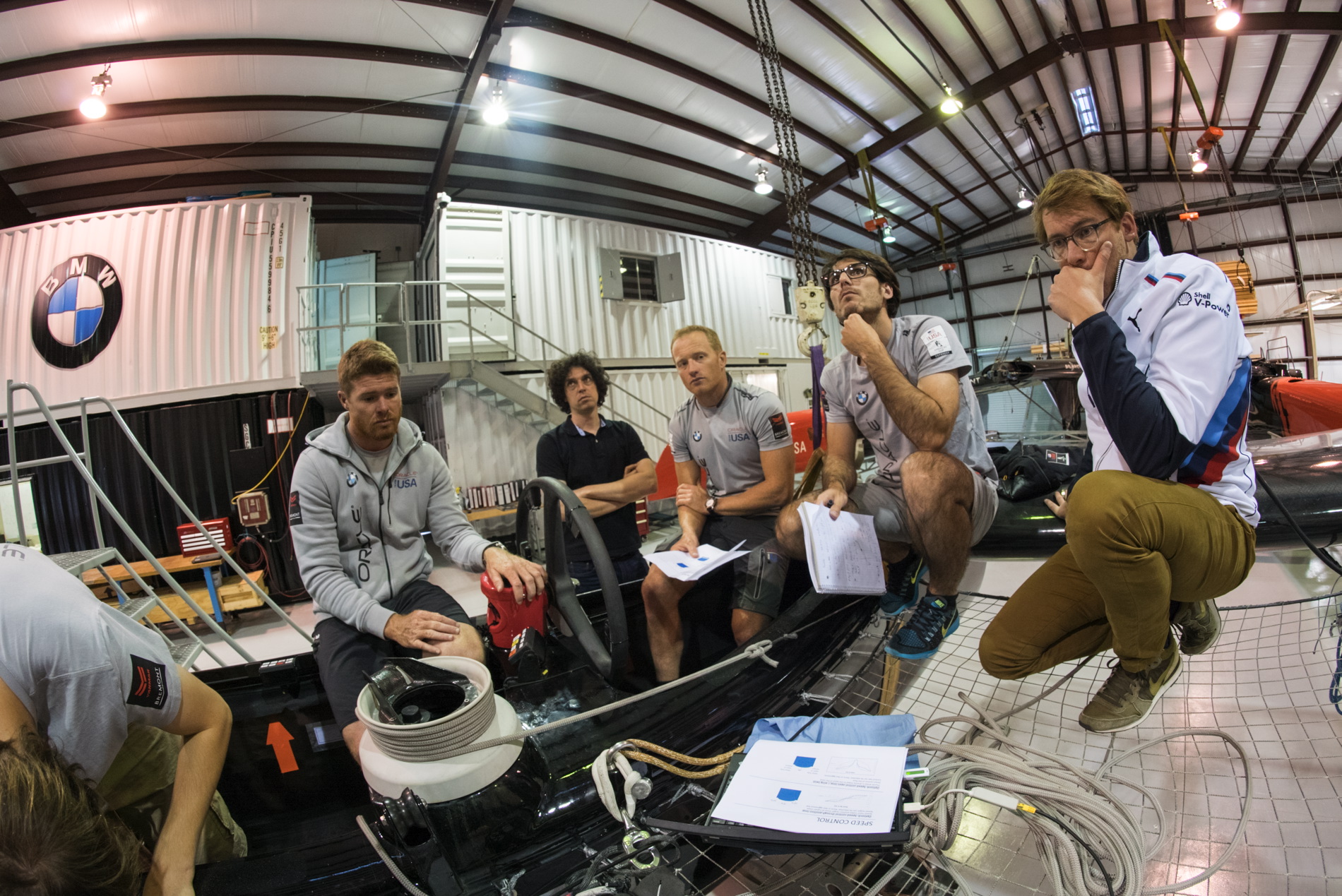

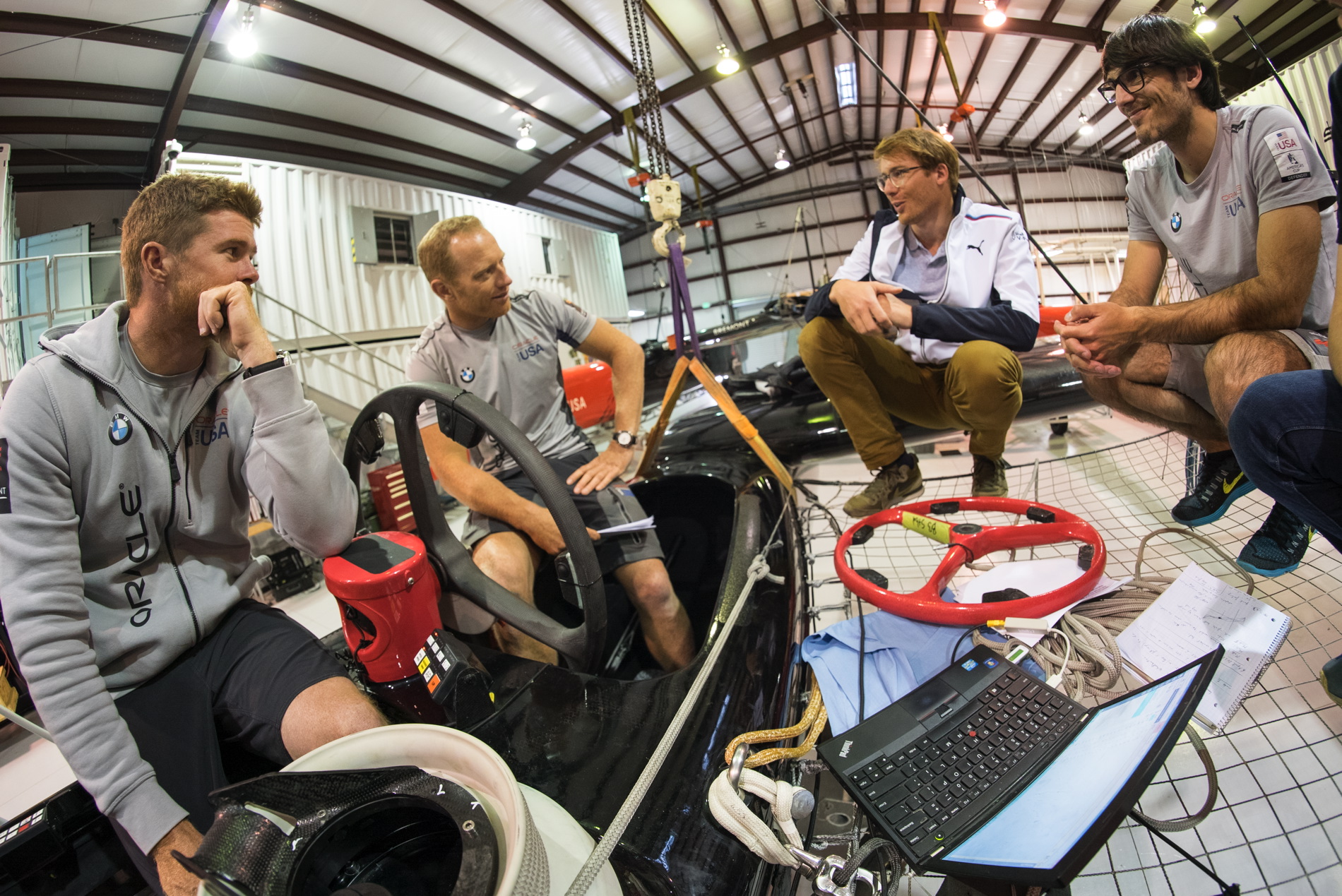

“The development cycles are short. It is important to develop concepts quickly in small teams, then to test, apply and optimize these – and then to repeat this cycle as often as possible,” says Hahn, who took on the responsibility of leading the structural team for the BMW ORACLE Racing Team, thereby playing an important role in the 2010 America’s Cup victory. The winning boat in the 33rd America’s Cup was a 90-foot Trimaran with a wing sail – one of the most spectacular, and most radical yachts seen in 165 years of a competition that demands the latest technological advances.

Hahn and Erbelding have also profited from this technological cooperation and have been able to apply their new carbon expertise in automobile construction for the BMW Group Research and Innovation Center.

“We have learned a lot from our colleagues at BMW ORACLE Racing, particularly the swift creation and evaluation of concepts. Paul Bieker, then in charge of the structural team and now head of design for ORACLE TEAM USA, is an expert in this field and shared a lot of tips and tricks with us. This helped us to improve our expertise in the area of layout and construction of carbon fiber prototypes in these dimensions.”

Technology transfer also proved helpful in the other direction. Expertise from the America’s Cup has been used in automobile construction, as Hahn explains when describing certification tests for the BMW i3 and the BMW i8 in the USA. The tests expect the roof of the car to withstand a certain amount of pressure, and to buckle a little.

“The tests are set with a normal chassis in mind, as metallic structures will give way under pressure. Carbon as a material is not taken into account,” says Hahn. “However, carbon fiber can resist great pressure with very little deformation. This is a property that we make use of in yacht construction all the time.”

However, to allow the BMW i3 to be homologated in the U.S., the carbon roof had to pass the test and buckle as specified – and a workable solution had to be found fast.

“Just like in the America’s Cup, we were able to take our expertise and implement it efficiently together with the development and assembly specialists at BMW,” says Hahn.

The result is a bracing that achieves the necessary deformation under the specified force. The components are then produced in the BMW plants in Landshut and Leipzig.