The upcoming BMW G30 5 Series is just around the corner, therefore the company is ready to start its communication process on it. In a recent press release, BMW announced that the upcoming mid-size sedan will be built using a new system called Optical Measuring Cell that will allow the production process to be more precise than ever. This new technology allows robots to build the new cars with an accuracy of less than 100 µm.

The BMW Group first fiddled with this system back in 2015, in an experiment held at the Munich plant. However, back then, it was only used in creating precise tools, for complete measurement of individual sheet-metal parts as well as tool inspection. This year though, as the new BMW G30 5 Series enters production, it will be used for the first time in the assembly process of a car, marking a world premiere.

“We are delighted to reach this genuine milestone in preproduction with the optical measuring cell: A single measurement provides us with a 3D data model of the total vehicle. Lengthy individual measurements and data collation are no longer needed – saving time and enhancing quality at the start of series production,” said Eduard Obst, Head of Geometric Analysis, Measuring Technology and Cubing, Total Vehicle.

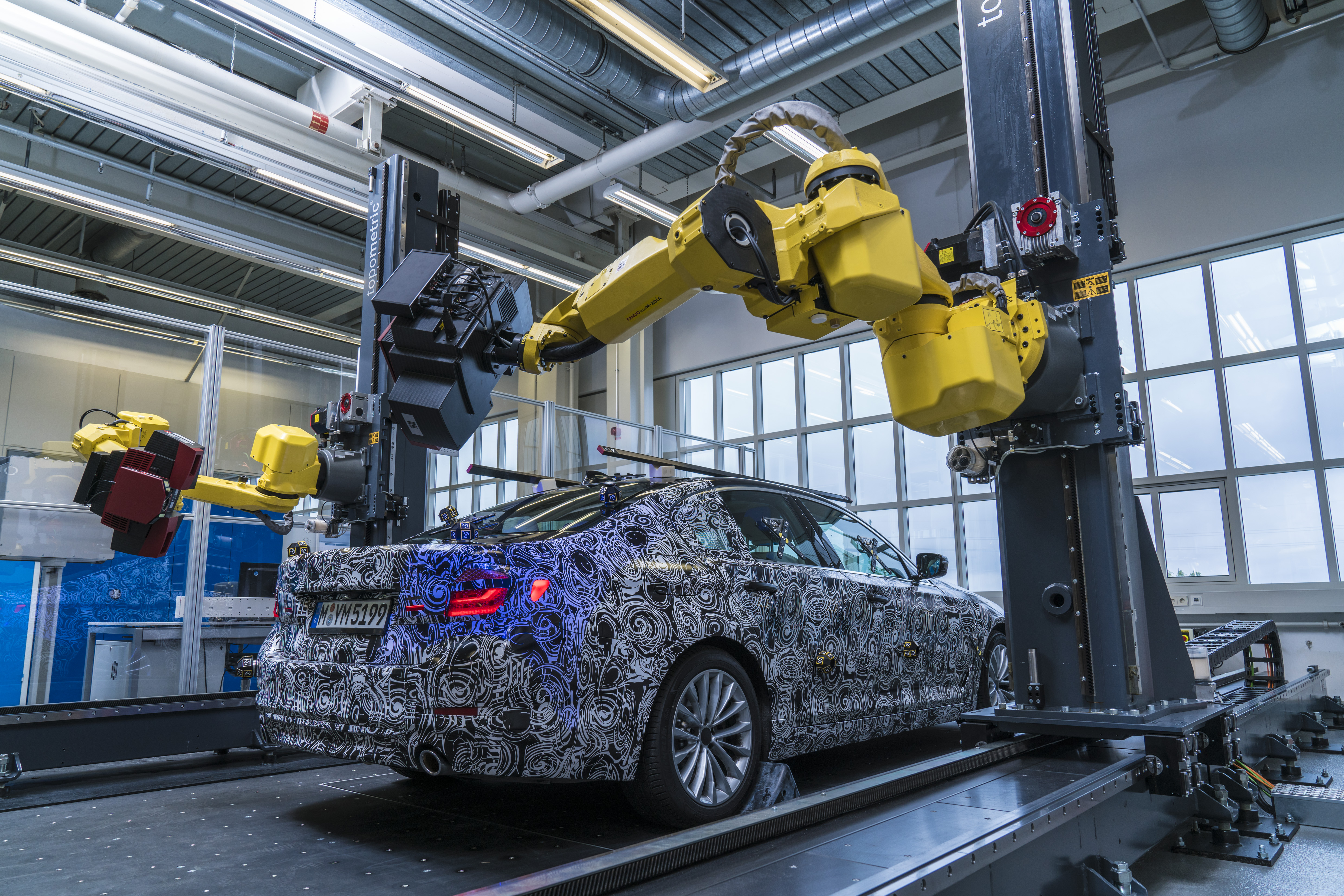

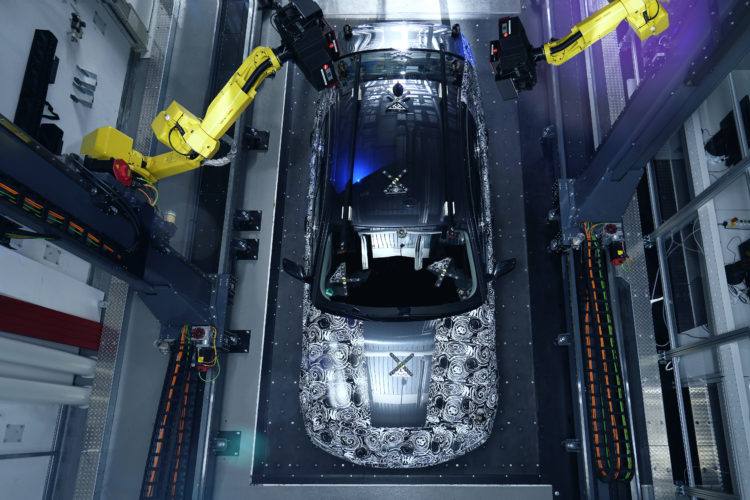

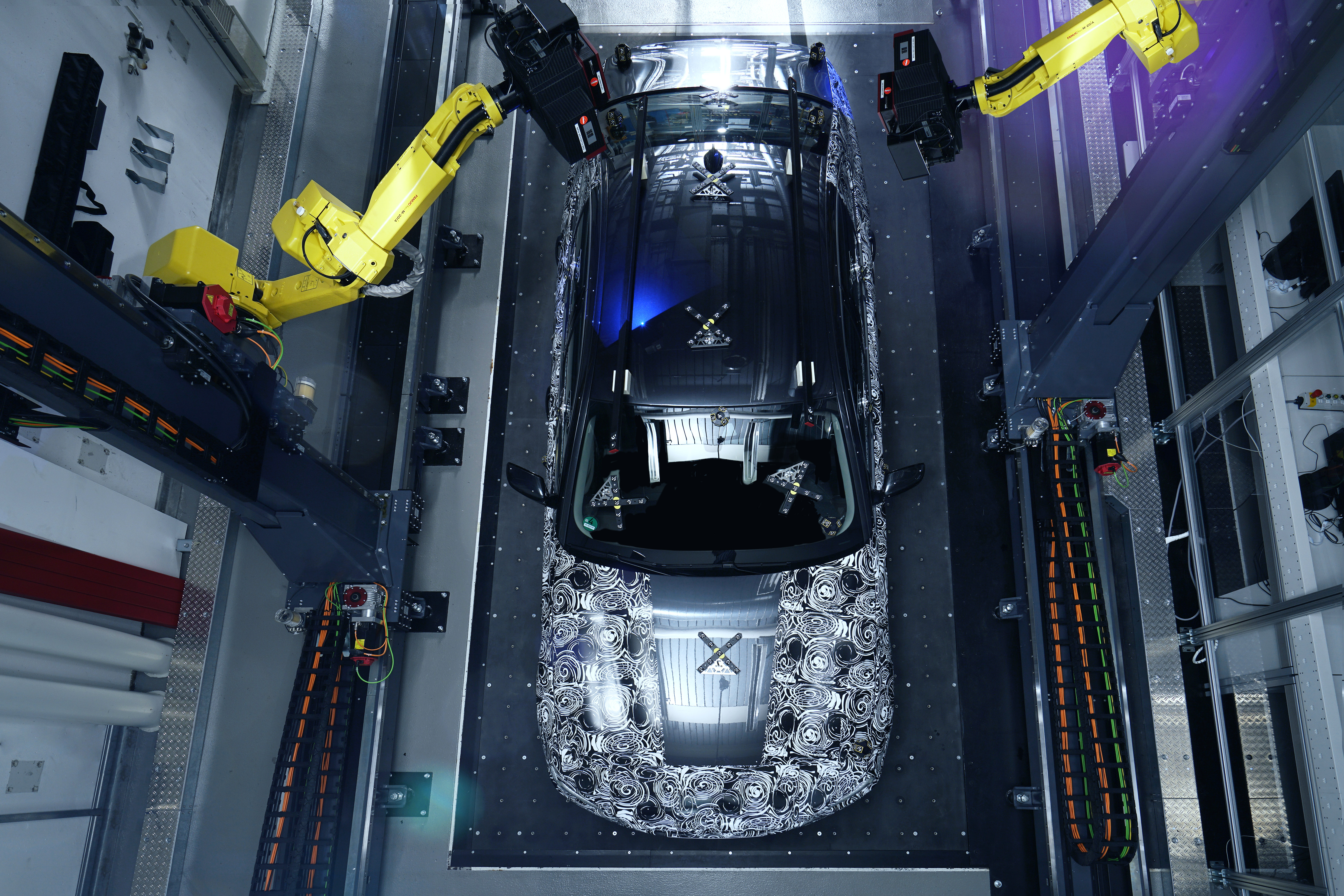

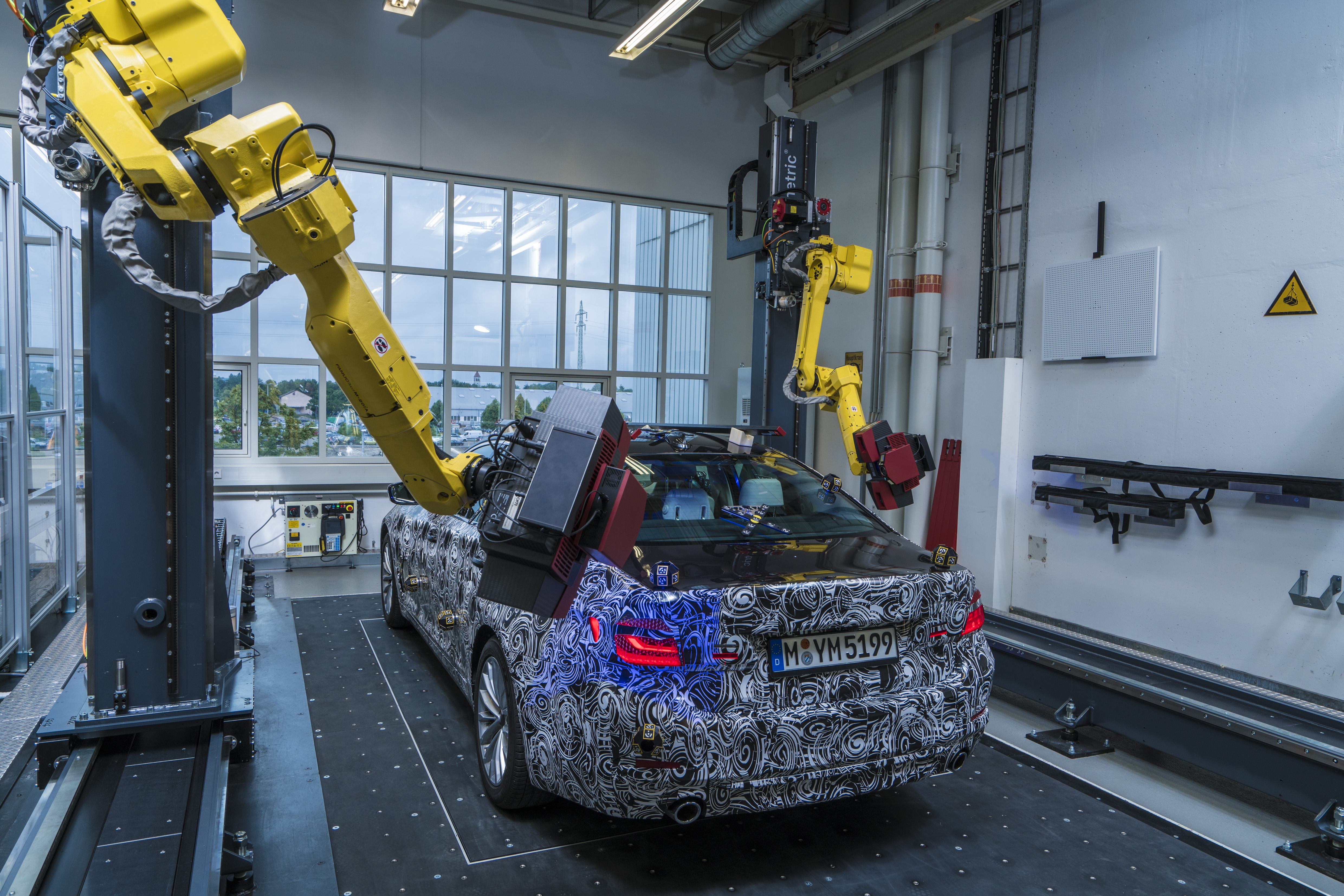

Freely moving robot arms use sensors to create a three-dimensional image of the entire vehicle and generate a 3D data model from the data captured, with an accuracy of less than 100 µm. This allows barely visible deviations to be identified at an early stage. A robot arm on rails mounted on each longitudinal axis of the optical measuring cell moves freely as it maps the vehicle in complete space. Occupying a relatively small area, this set-up allows two small, flexible robots to be used in parallel in an optimum working range.

Compared with previous processes, in which robots use a single sensor to record one side of the vehicle after the other, measurements now only take around half the time and are completed within just a few days. The robots are fitted with two sensors that record reference points and then capture individual surface areas of approx. 80 x 80 cm each. These are combined to form a scan of the entire vehicle. Analysis of the data quickly reveals any deviations, allowing technical integration specialists in the Production division to take appropriate action early on. The BMW Group is currently working on ways to bring this new technology to other plants around the world as well, to further increase efficiency and product quality.