MINI has been successfully racing in the Dakar Rally for quite some time now, winning various titles and an unexpected amount of races in the last few years. For the 2017 season, the British manufacturer decided to upgrade its game and today we’re taking a look at the new car they’ll be using in the famous rally. As you might expect, the Countryman is the base car for the rally car, hiding underneath a completely different setup.

During the MINI John Cooper Works Rally design, development and build processes, many key areas came under scrutiny and have been extensively reworked when compared to the former cross-country rally car. The following key areas have been priority subjects to deliver a totally new formidable racing package: aerodynamics, thermal management, weight distribution, lower center of gravity, modified chassis frame design, new engine mapping.

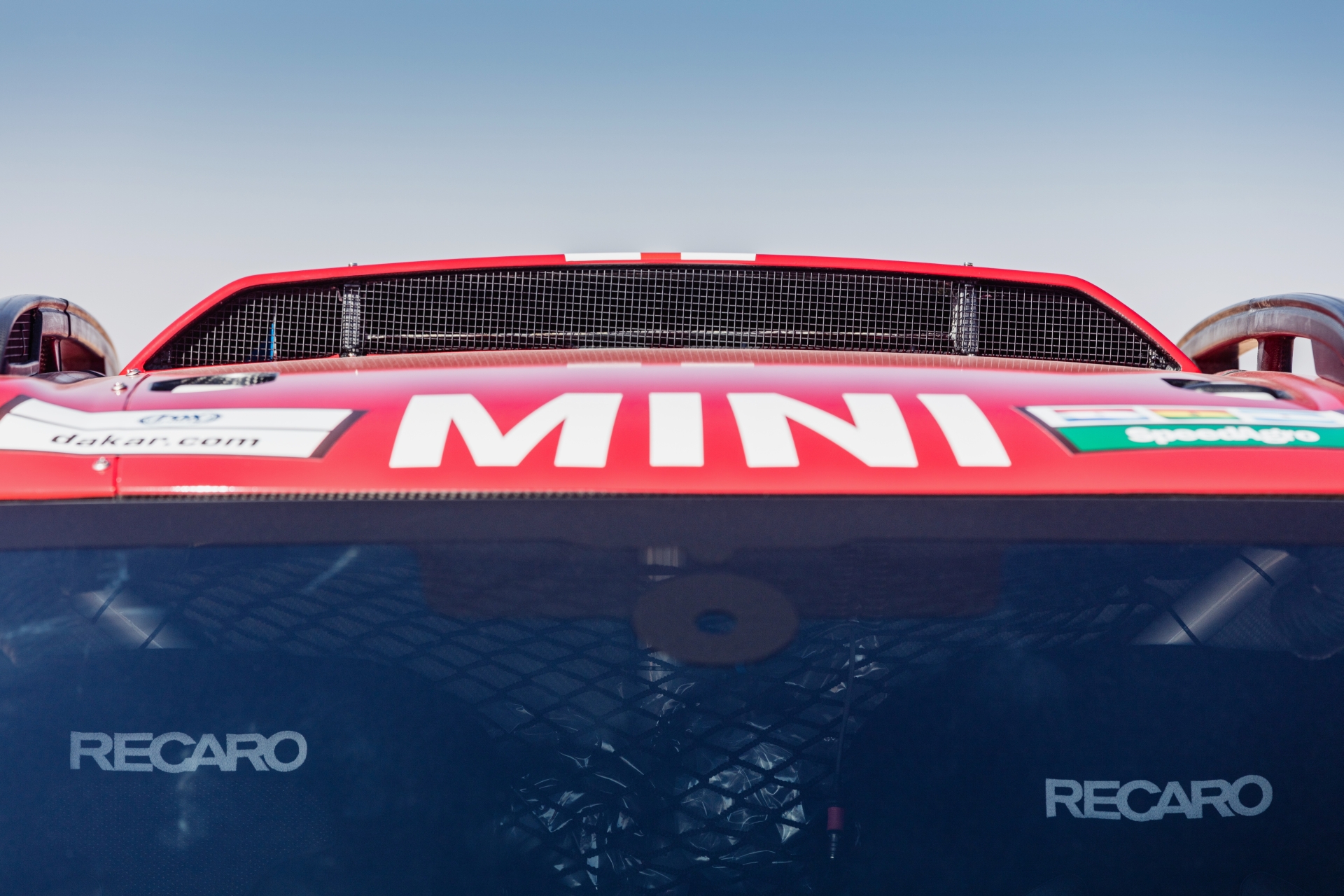

Composite bodywork e.g. carbon fiber and Kevlar is used for the MINI John Cooper Works Rally outer shell, which still resembles the Countryman, while a honeycomb mix of the same materials is used for an underside tier. The use of such materials is threefold: 1) strength and durability – ideal for additional safety protection of the two-man crew 2) reduced weight with greater strength, and 3) panels are easily removed or replaced during servicing periods or if damaged.

Under the body you’ll find three spare wheels along with two hydraulic jacks that can be operated from inside the cabin. Furthermore, the subframe was constructed from tubular steel to aerospace standards. Designed specifically for the demands of cross-country racing, the frame is constructed to exacting standards by CP Autosport. What makes this even more special is the fact that MINI Motorsport partner X-raid devised this subframe to be removable. Such is the design of the chassis and the new subframe; complete engine removal, if required, can be completed in just over one hour.

Suspension is provided by specialists Reiger Racing Suspension. Each axle rides on four fully adjustable suspension units (two per wheel) providing the permissible 250mm wheel travel. Six-piston calipers all-round act on 320mm vented steel discs. To ensure consistent braking performance while under the stress of racing conditions for hours on end in high ambient temperatures, the rear brake calipers are air and water-cooled.

Under the hood you’ll find a 3-liter straight six BMW engine making 340 HP at just 3,450 RPM along with 800 Nm (590 lb-ft) of torque at 1,850 RPM. The engine’s ECU was also upgraded to make sure it can handle anything thrown at it, from the Bolivian mountain sections approx. 3,000 meters above sea level with low oxygen air to the scorching heat of the deserts covered throughout the Dakar Rally.

The driveline features an AP Racing clutch combined with a six-speed SADEV sequential gearbox. Lockable, oil-cooled Xtrac front and rear diffs with a central SADEV unit to deliver maximum engine performance at all times regardless of the terrain and racing conditions. Also helping to stir the blood of MINI Motorsport and MINI John Cooper Works fans will be the exhaust tone of the MINI John Cooper Works Rally. The Akrapovič exhaust is a new design with rear outlet.

“Introducing the famed MINI John Cooper Works sub-brand within the exciting arenas of rally raid, cross-county rally and the endurance challenges of the Dakar Rally and Silk Way Rally seals MINI’s commitment to this spectacular and compelling motorsport. This racing spirit will always be a part of MINI’s genes and products. The competitive debut of the MINI John Cooper Works Rally at the 2017 Dakar Rally is a tough debut indeed. The Dakar Rally is the epitome of long-distance rally, where the competitive stress placed on man and machine is like no other but perfectly represents the sporting spirit of MINI Motorsport and the John Cooper Works sub-brand,” said Sebastian Mackensen, Senior Vice President MINI.