When the six new BMW M4 DTMs take their place on the grid for the DTM season-opener on 6th May 2017, it will mark the temporary end of a long and intense period of development. A considerable part of this development took place with the aid of computer simulations. It is hard to imagine car development without computational fluid dynamics (CFD) these days.

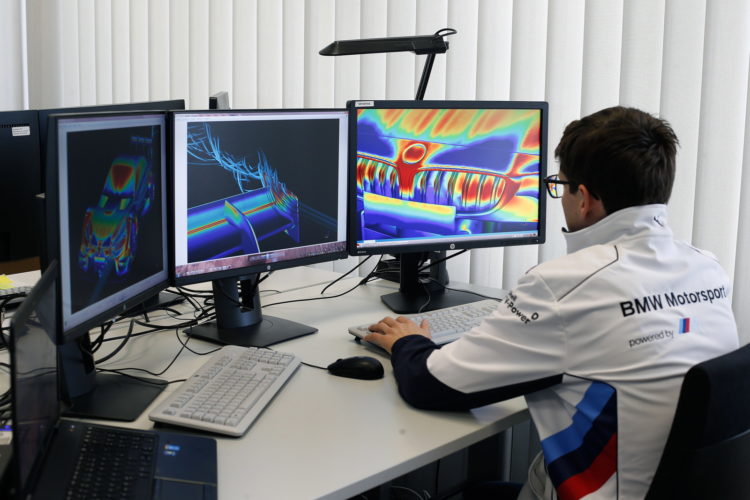

During the creation of a new race car, the smallest details can bring about a decisive advantage in the battle for those fractions of a second on the circuit. It is no wonder that the BMW Motorsport engineers leave nothing to chance. That is why the CFD flow calculations are of such special importance. The development of digitalisation has changed racing car design. Engineers can identify the most promising solutions for specific components without leaving the computer.

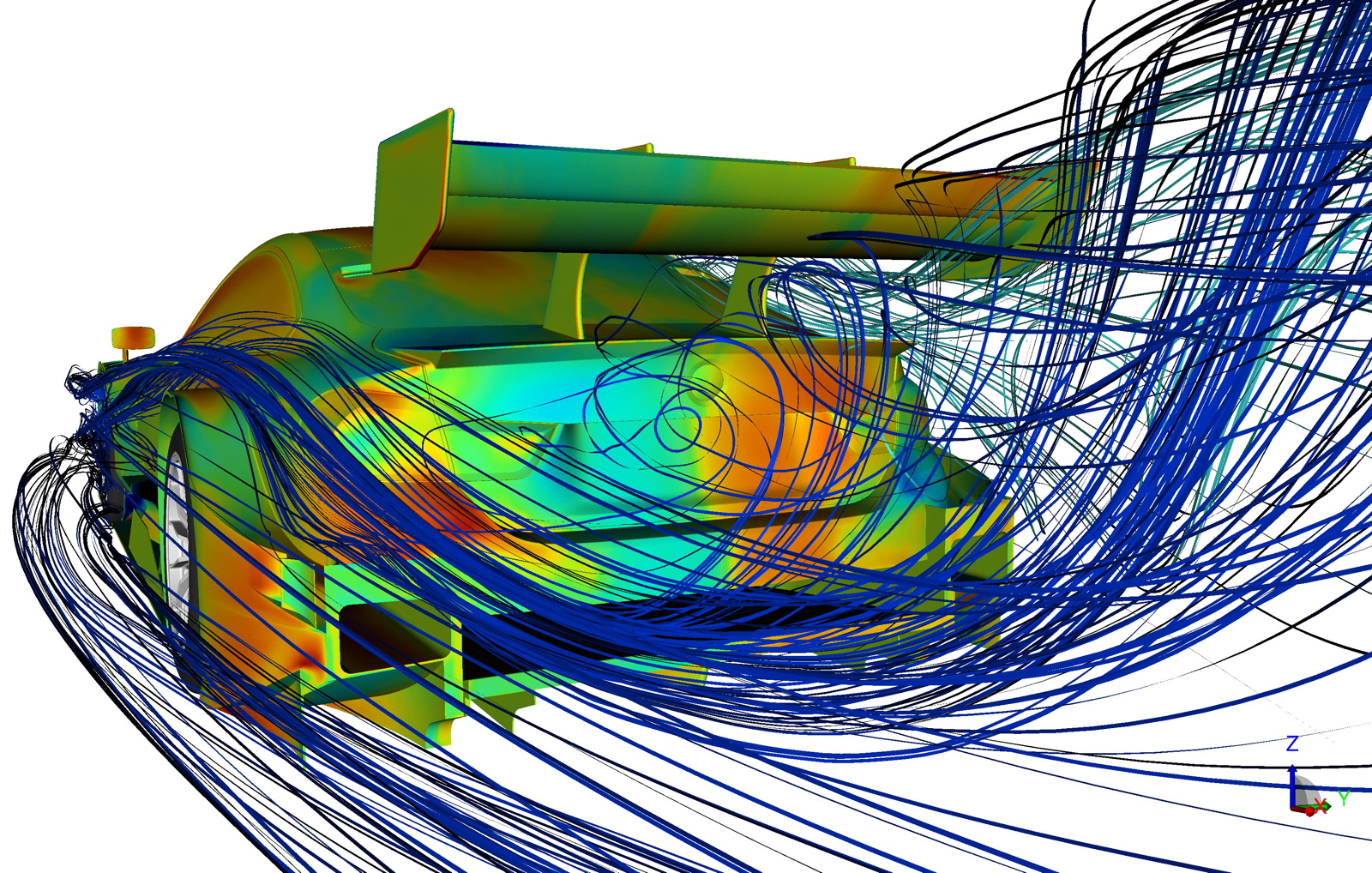

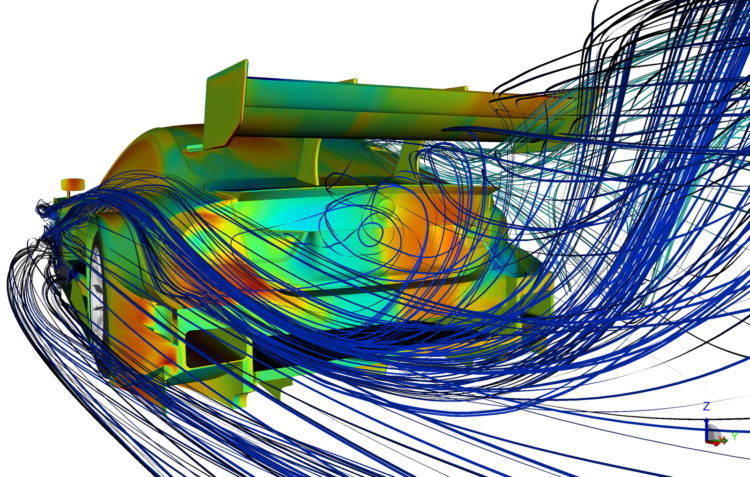

On computers, the aerodynamics experts simulate the effects of changes to the individual parts of each car – before the components have even been built. In the calculation, the model is split into a grid of 500 million three-dimensional cells, and the virtual airflows through them. Each of the cells can be separately analysed, sometimes for an entire day, depending on the type of simulation. Only half of a vehicle is required, as the air flow for straight-line travel is identical for both sides of the car.

BMW Motorsport employs experienced aerodynamicists to interpret the calculated values. Despite the quality of the CFD simulation, the technical expertise of the aerodynamicists is still a decisive factor in drawing the correct conclusions from the results. After precise analysis of the pressure distribution, flow lines and many other details, the aerodynamicists can make a specific recommendation for changes to be made to the components. If the part has proved itself during simulation, variations are tested in the wind tunnel on a scaled down, 60 per cent model. The computer-aided flow simulation is not intended to replace wind tunnel work, but complements it.

The preliminary calculations are dealt with by an armada of high-performance computers. BMW Motorsport uses the BMW cloud system to dynamically adjust the number of computers in use, and adjust the load for other users within the BMW Group. This bandwidth and availability of computing power means that it is possible to perform multiple calculations in parallel. The result: even more efficiency and precision in the development of BMW Motorsport racing cars – like the new BMW M4 DTM.