One of the issues car makers had to address related to the manufacturing of electric cars was that some of the materials needed for the batteries can cause a lot of issues. Sourcing them is problematic, to be more direct. BMW promised its fifth-gen powertrains won’t require rare earths anymore and whatever other materials they would need will be sourced responsibly.

A while back, the German company announced it will be getting its cobalt from Morocco and Australia only, so that they can watch the supply chain. Today, BMW announced a new supply contract with Managem Group, spreading from 2020 to 2025 for cobalt worth about €100 million.

This order will cover about 20% of the company’s estimated needs over the next five years, the rest of it being sourced from Australia. “Cobalt is an important raw material for electromobility.

By signing this supply contract with Managem today, we are continuing to secure our raw material needs for battery cells,” said Andreas Wendt, member of the Board of Management of BMW AG responsible for Purchasing and Supplier Network.

“For us, ethically responsible raw material extraction and processing starts at the very beginning of the value chain: We take a keen interest in battery cell supply chains that extends all the way down into the mines themselves,” said Ralf Hattler, Senior Vice President Purchasing Indirect Goods and Services, Raw Material, Production Partner at the BMW AG. BMW already publishes the countries of origin for the cobalt it uses on its website (see here).

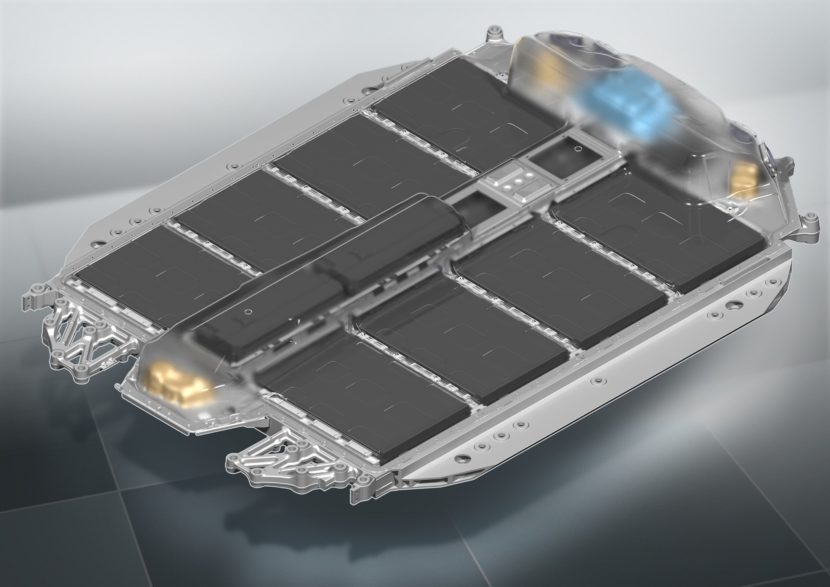

For the fifth generation of battery cells, the company has also restructured its supply chains and will source lithium, as well as cobalt, directly from 2020 and make these raw materials available to its two battery cell manufacturers, CATL and Samsung SDI. This ensures full transparency over where raw materials come from.

The BMW Group will also cease to use rare earths in its fifth-generation electric drive trains from 2021 on. “This means we will no longer be dependent on their availability,” said Wendt.