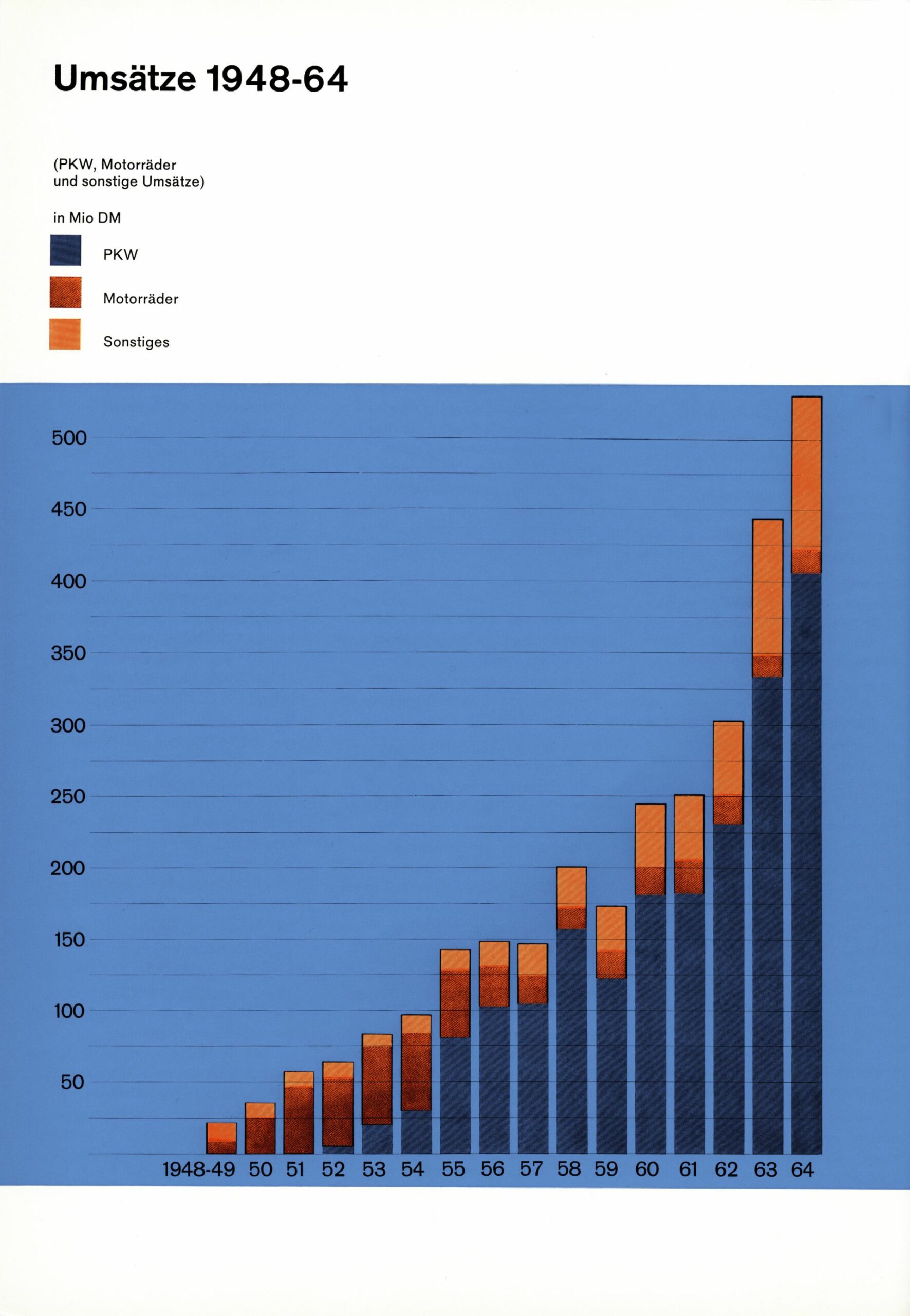

BMW has a long history behind it and, as one would expect, since it’s based in Germany, it has gone through a lot in the last century. Having faced two world wars that basically destroyed the old continent and in which Germany was on the losing side, twice, BMW had to face some truly hard times. Nevertheless, the Bavarians managed to rise from the ashes every single time and reinvent themselves. Today we’re taking a look at one of the least known chapters in its history, otherwise known by historians specialized in the BMW brand as the ‘Notproduktion’ concept.

Germany was in shambles after the second World War and the fact that it had been split in two by the Iron Curtain definitely didn’t help. The sanctions imposed on the country were tough and German companies had to pay for a lot of them, with their own technologies and tools. BMW, for example, lost a lot of its production plants, some of them being left on the Eastern side of Germany (now taken over by the communists) and some being confiscated by the American army, for various purposes.

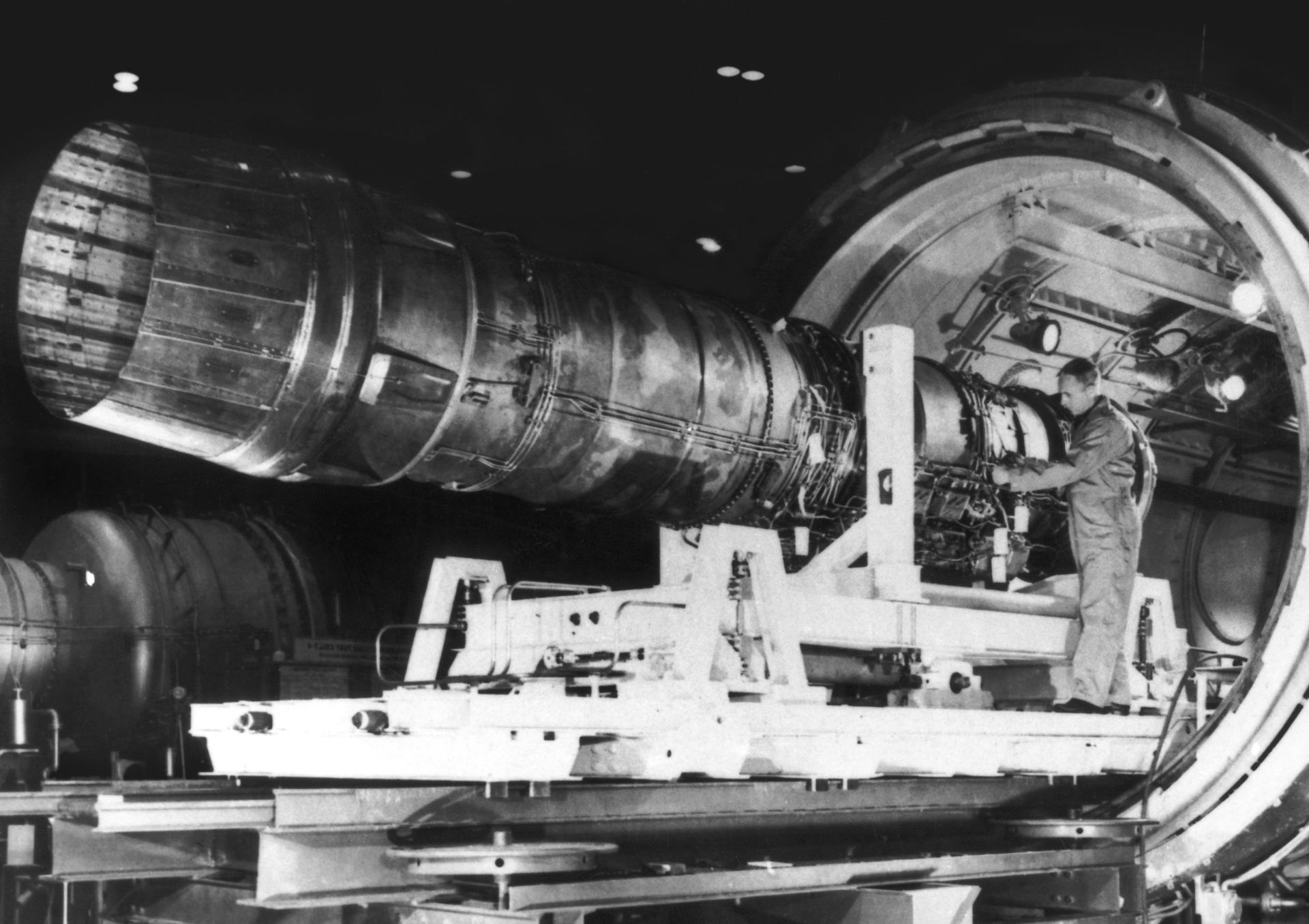

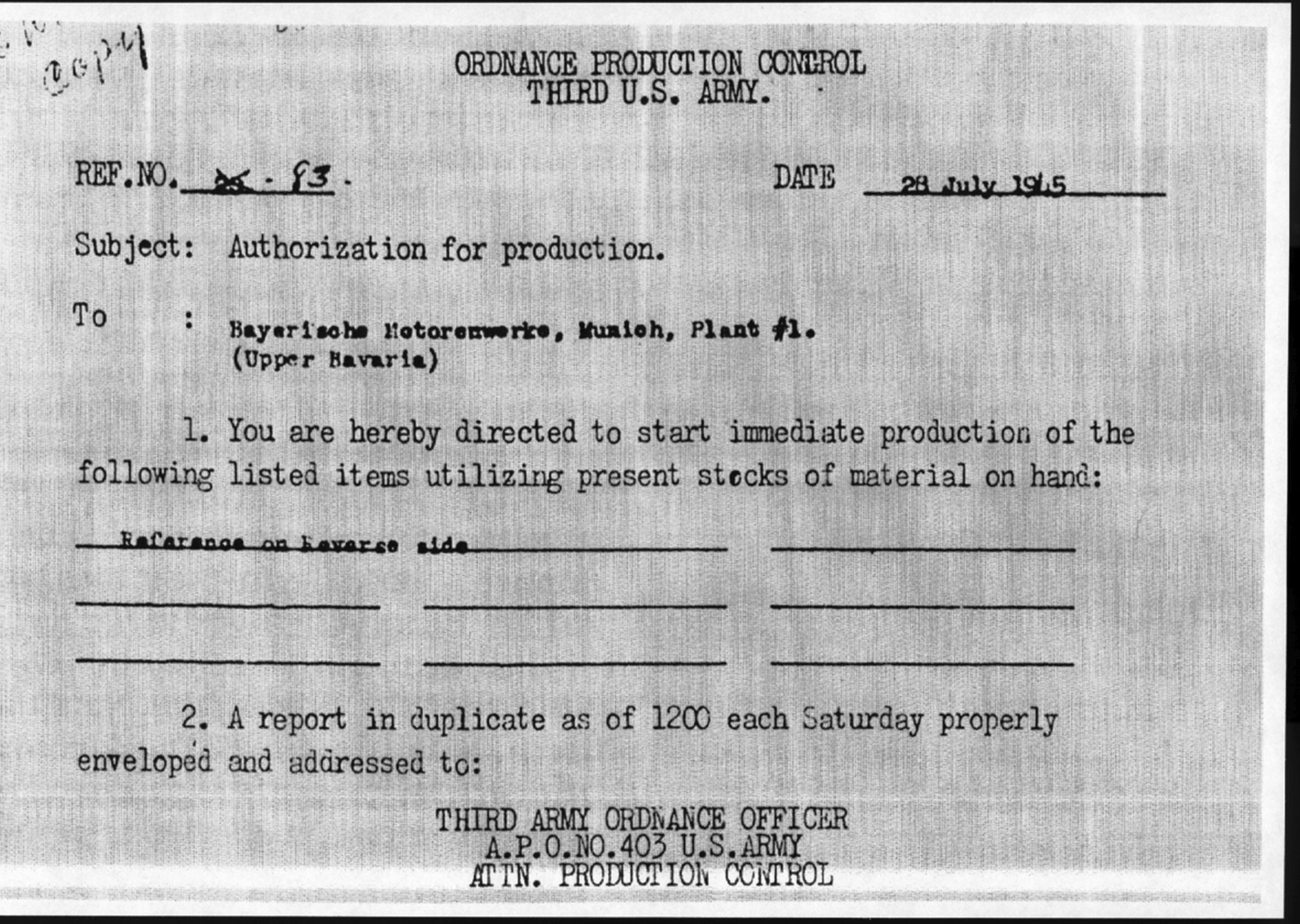

BMW had been forbidden to return to manufacturing ways up to July 28, 1945. That interdiction covered everything, not just cars and motorcycles, but every single widely consumed item you could think of. Thankfully, the company gets a license to start manufacturing again and from March 26, 1946 on, BMW was allowed to start making motorcycles again, an encouraging step if you will.

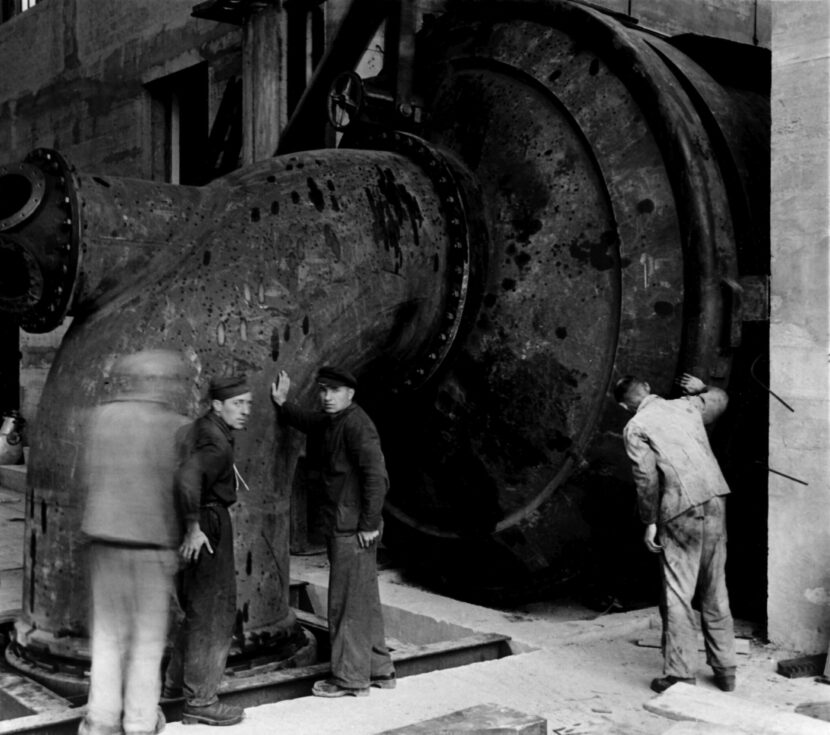

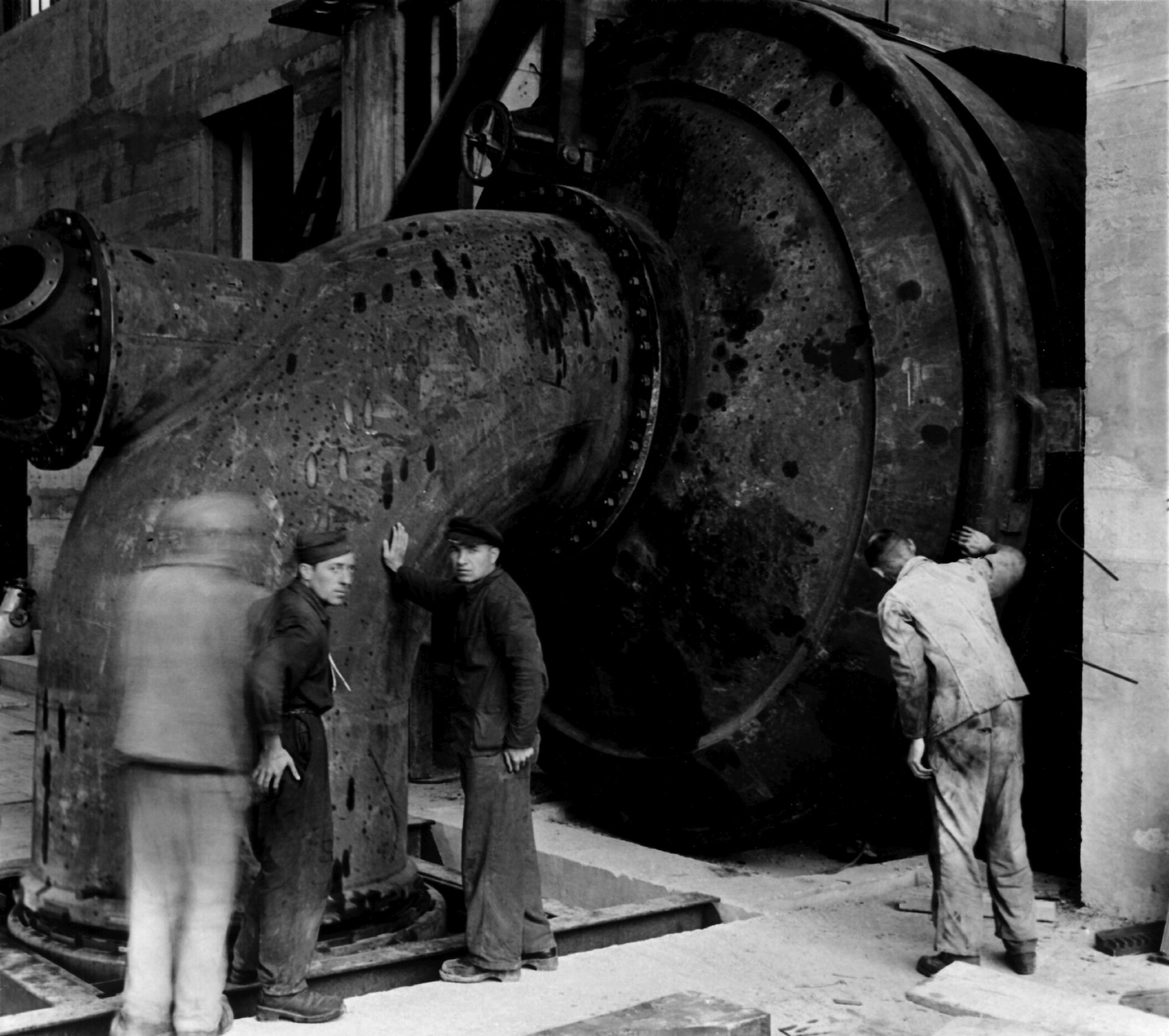

Even so, part of the Munich and Allach plants, BMW tools and workers were still busy working of repairs and maintenance for the American Army. As a matter of fact, the Karlsfeld Ordnace and Maintenance Depot is set up at Allach, becoming the biggest repair center for the American Army on the entire European continent. While it may seem like forced labor, this deal allowed the company to gain access to resources to start manufacturing items for its own sake.

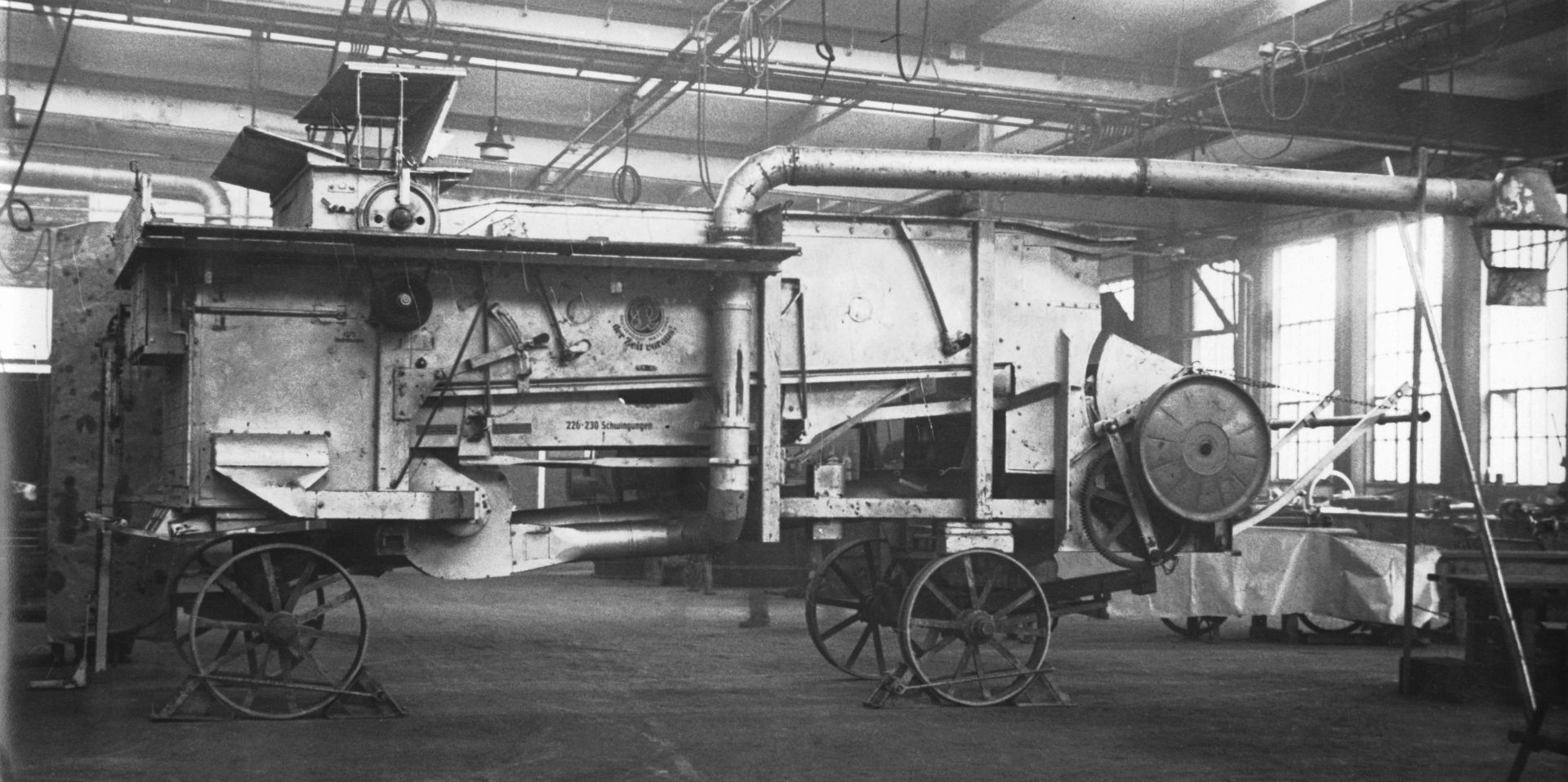

Most of its technology and tools had been sent overseas by 1946 and it wasn’t until the 1950s and 1960s that the buildings BMW had were fully repaired and therefore resuming production of any kind was problematic. Forced by the circumstances, BMW tries to reinvent itself and the Notproduktion kicks off, a sort of crisis production, a concept that was familiar to BMW, as it was used once before, after the First World War.

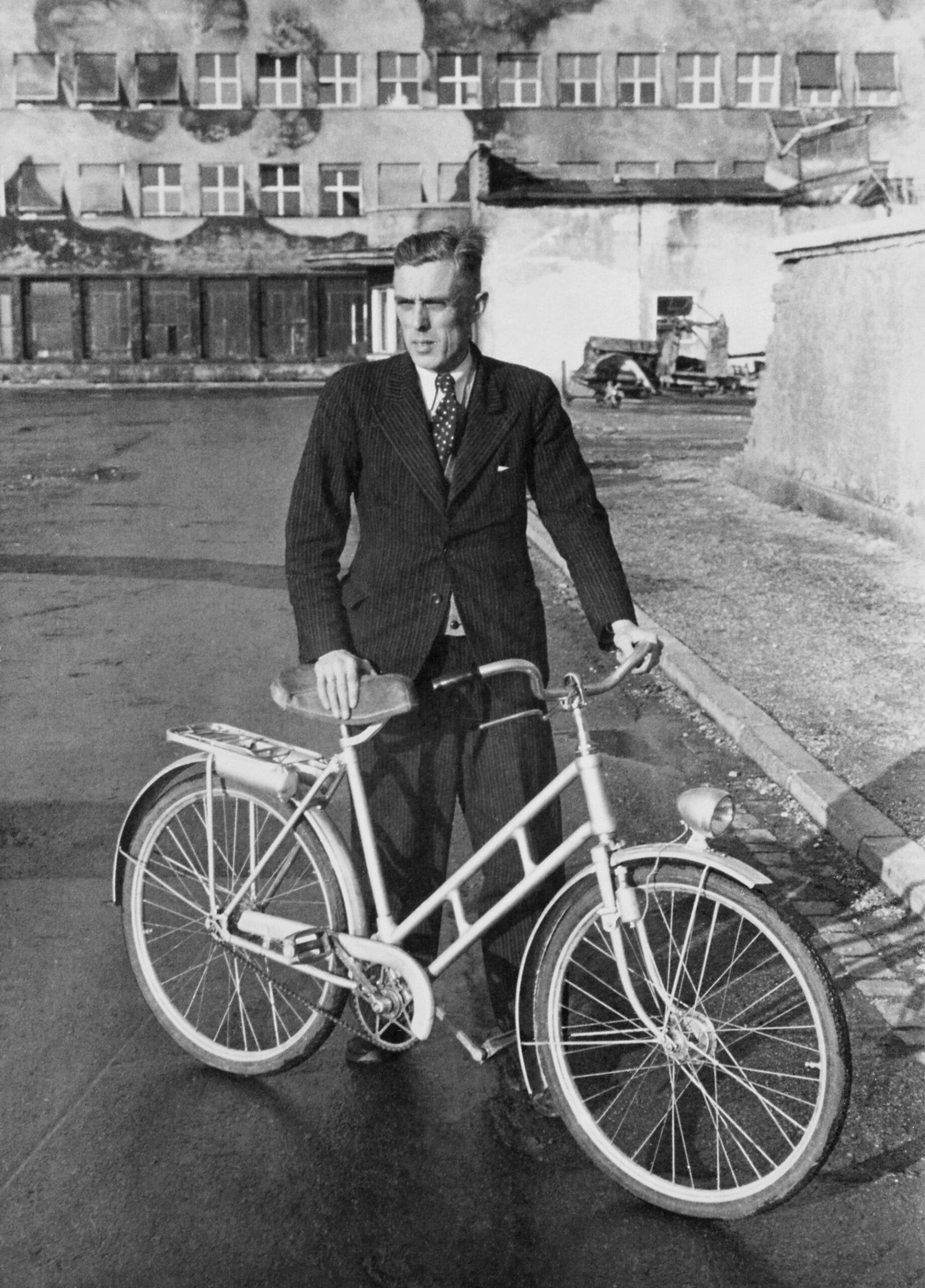

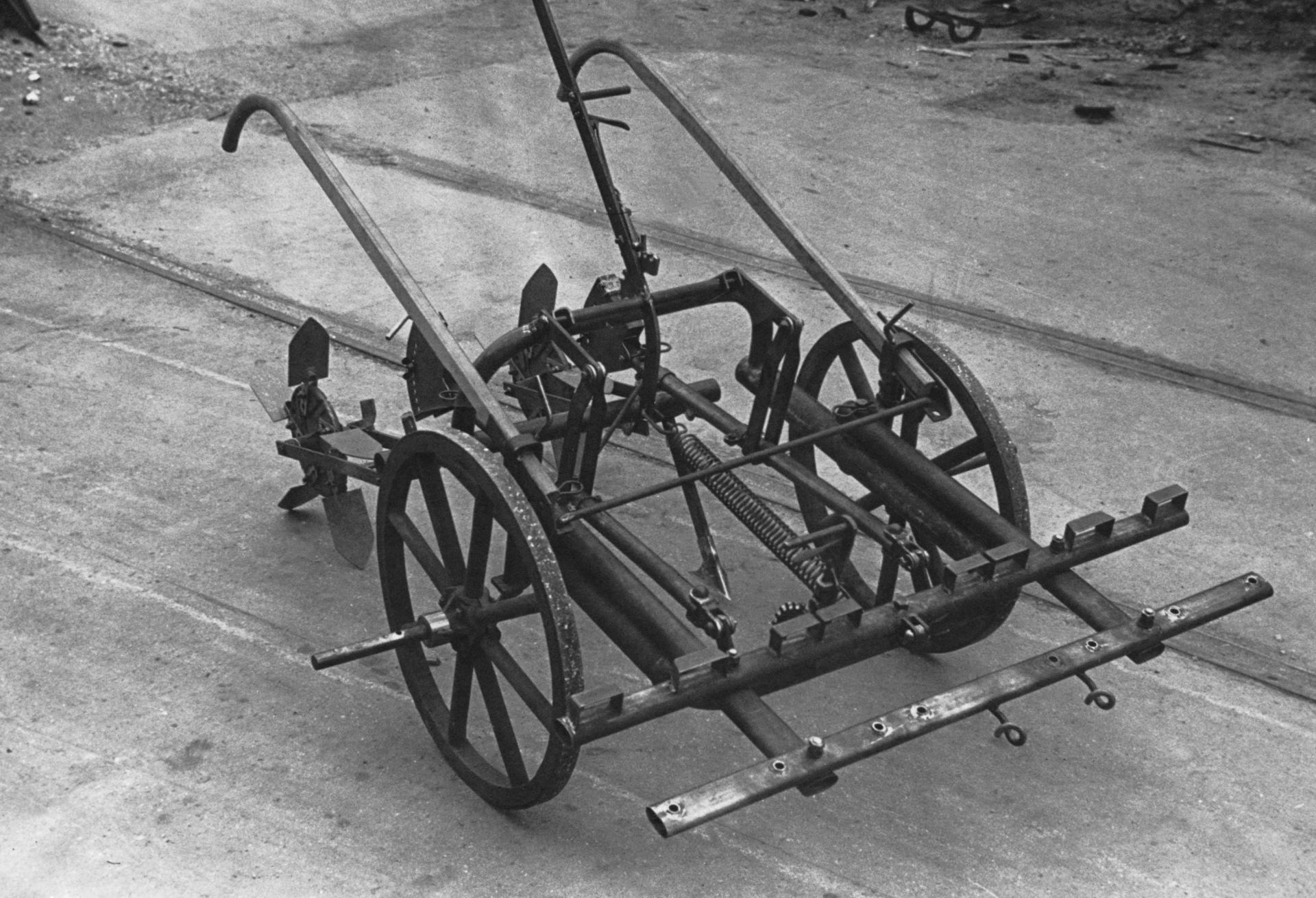

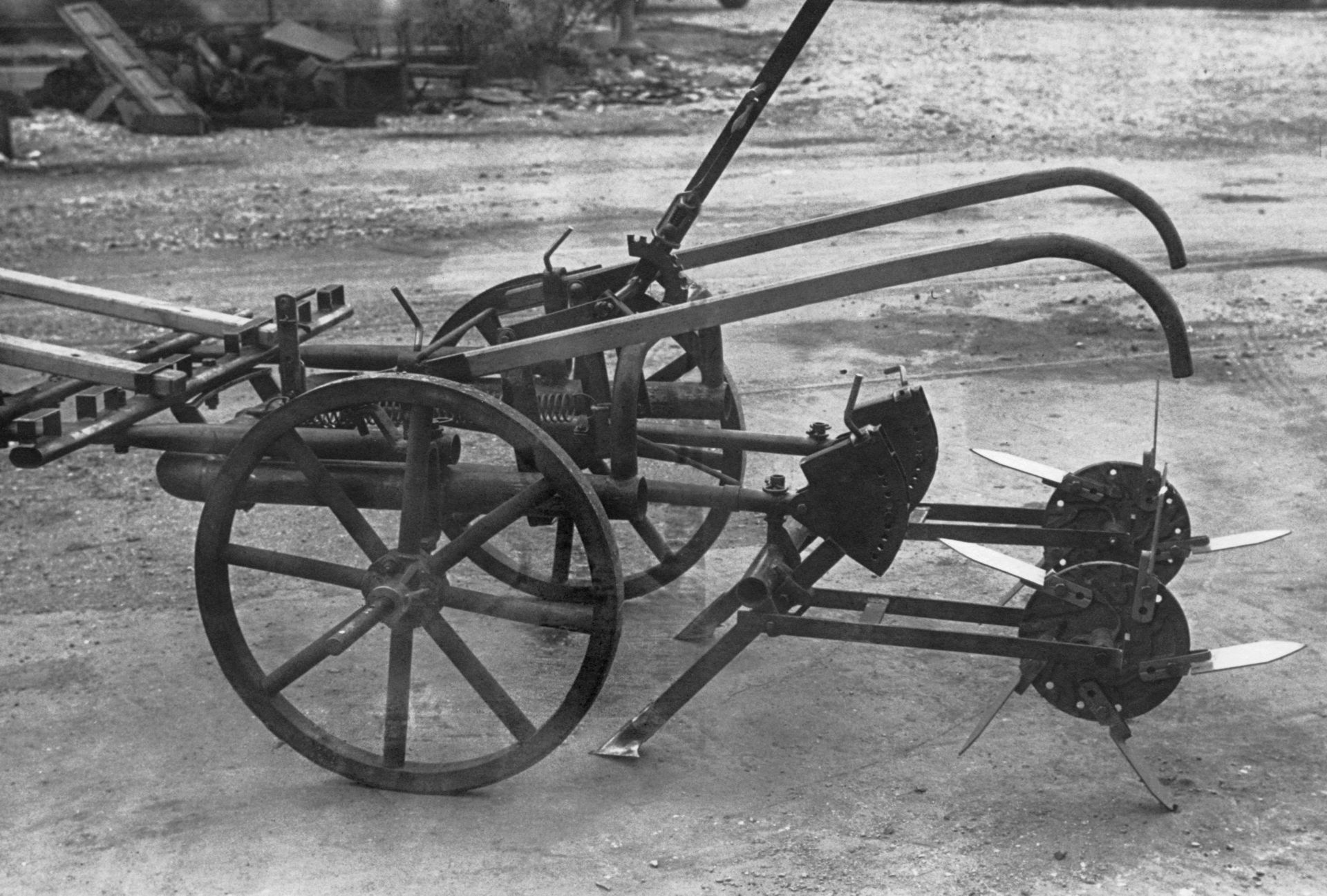

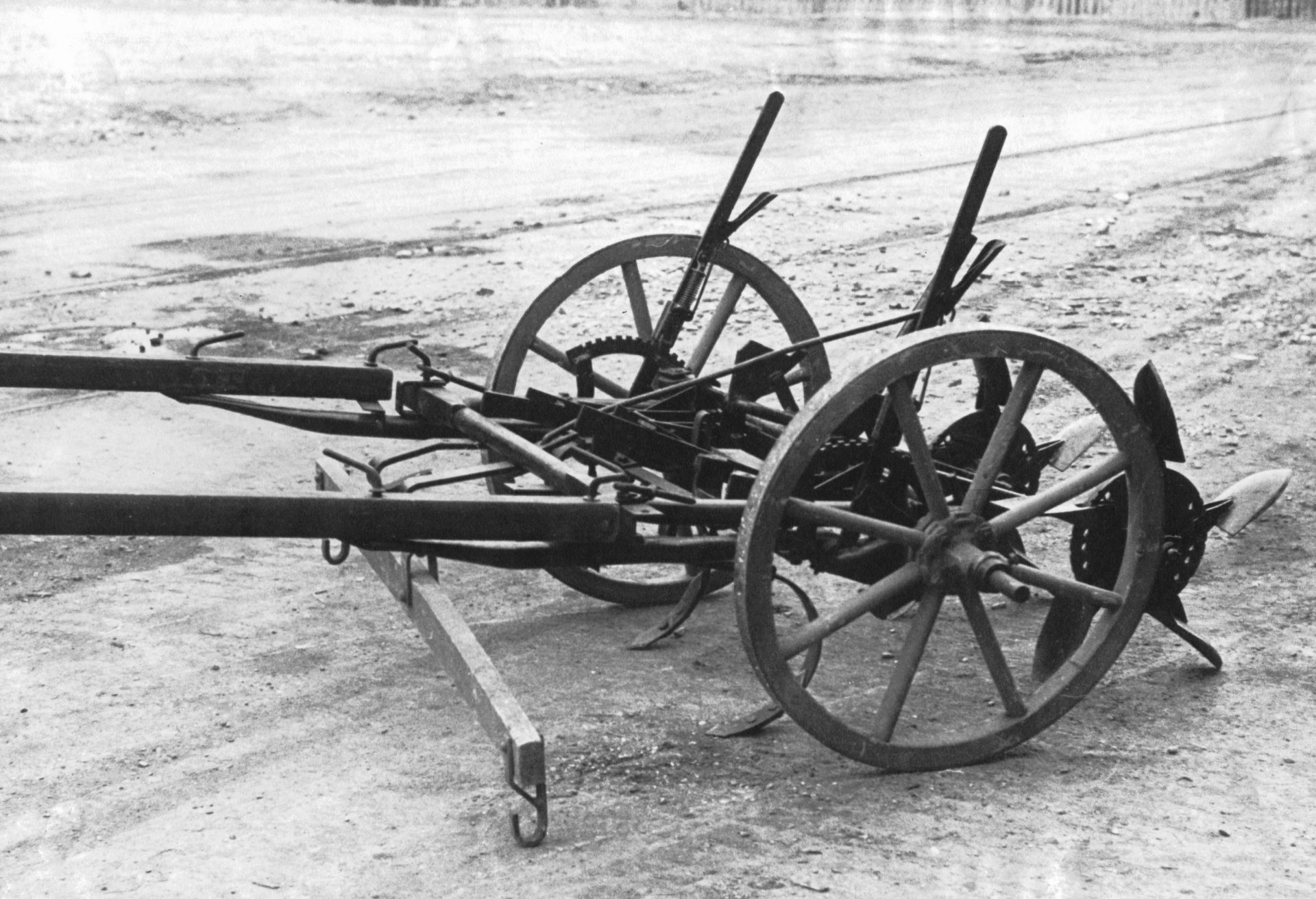

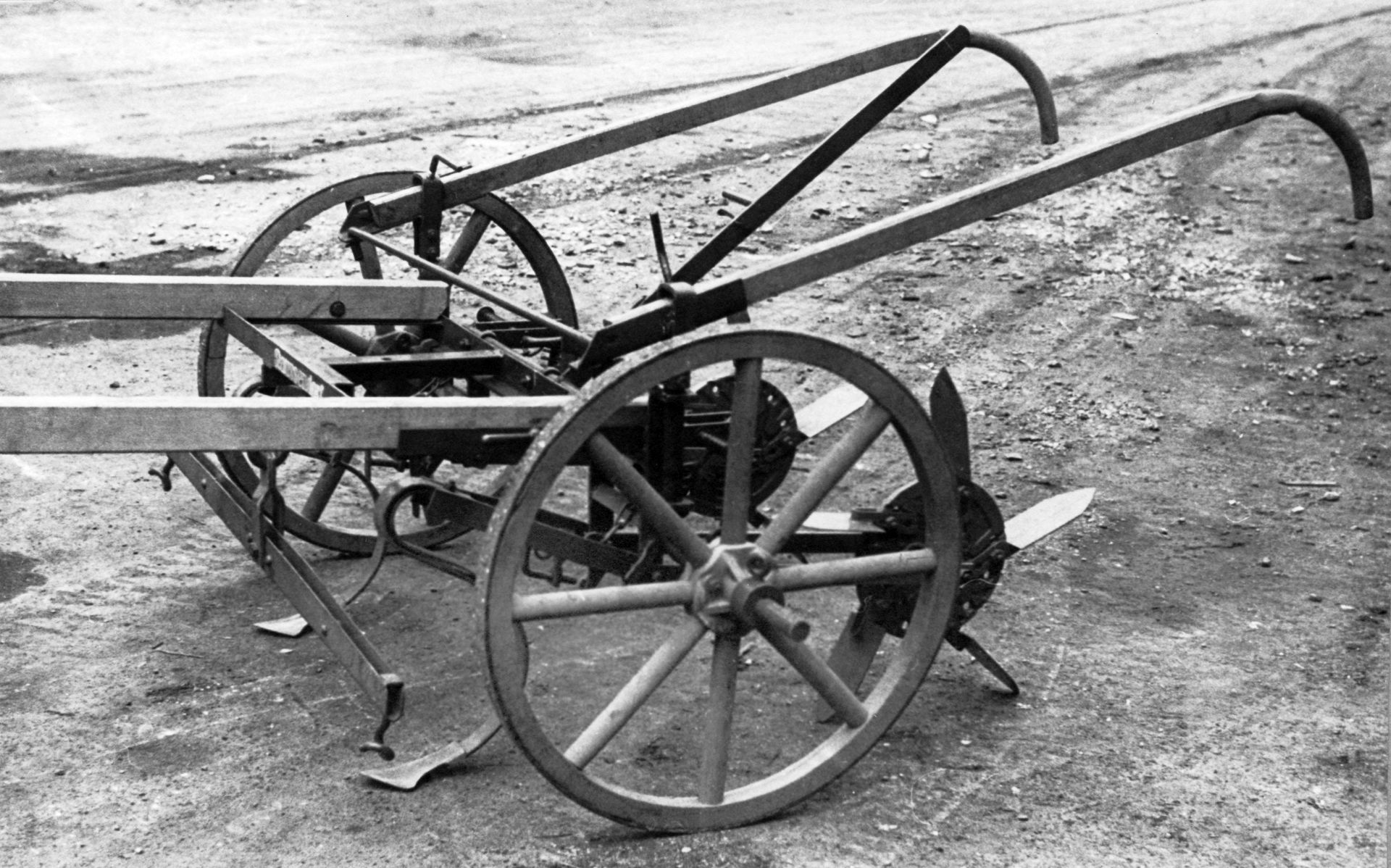

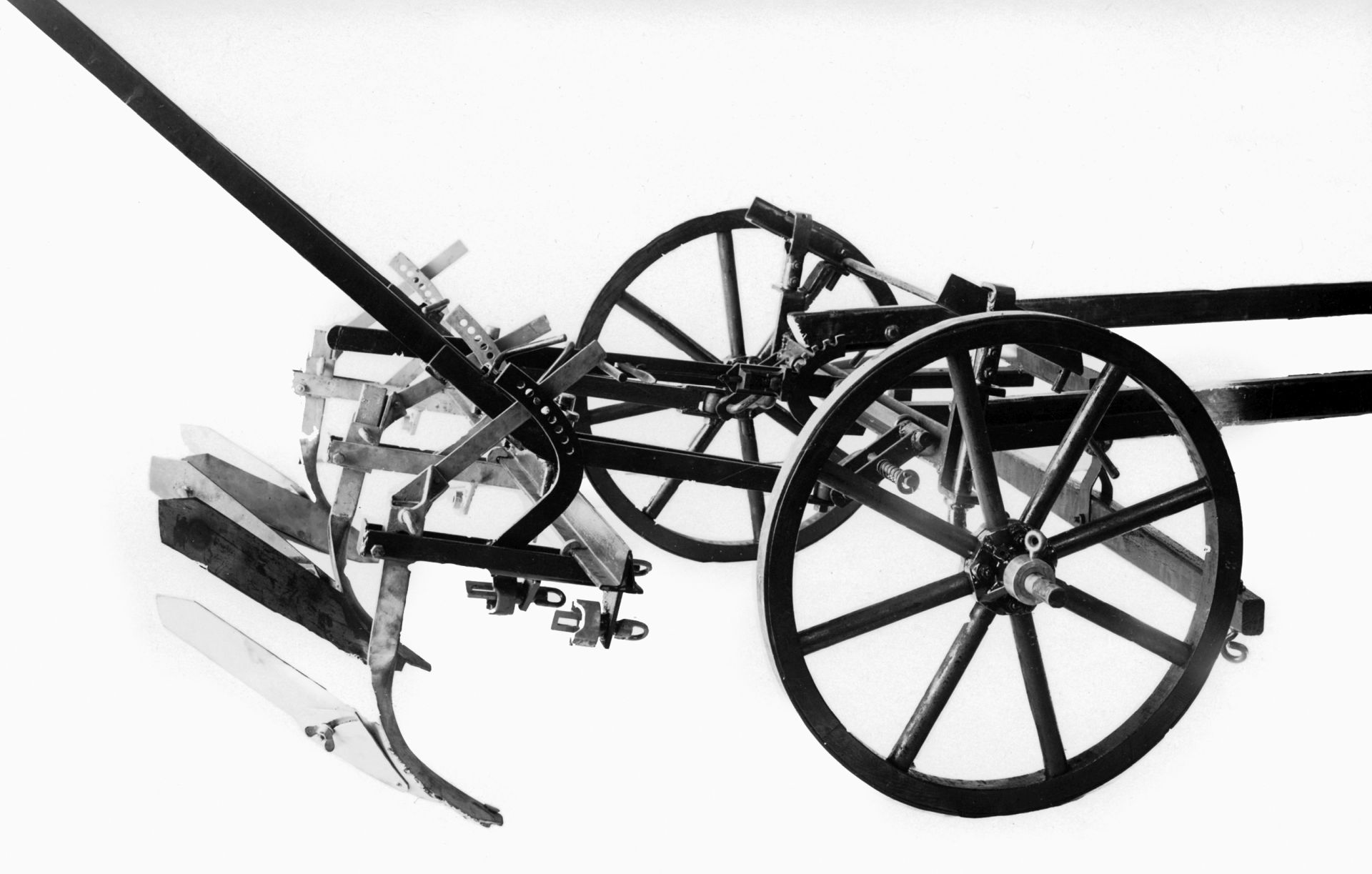

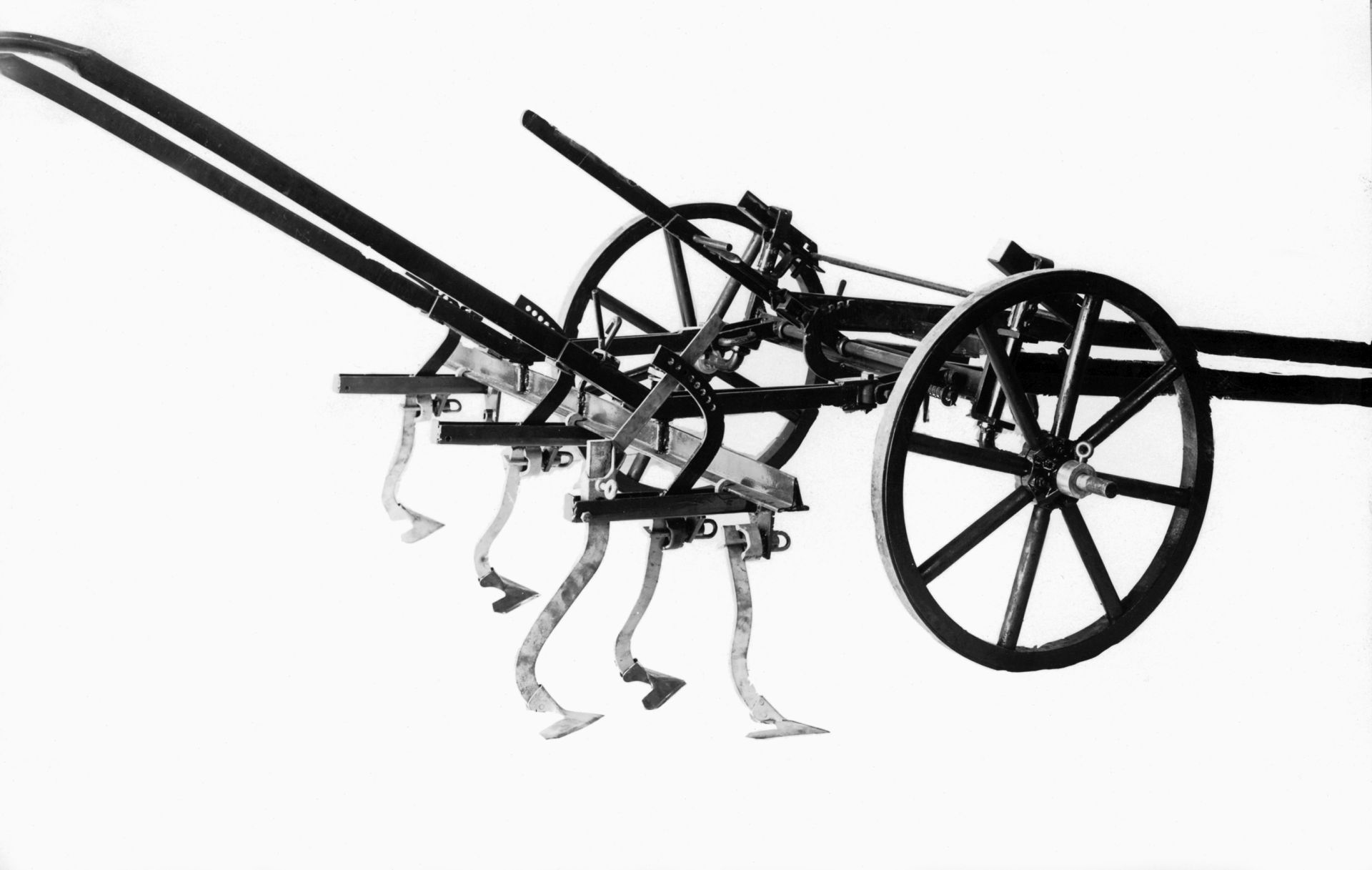

Given that most of the technical documentation for making cars and motorcycles had been lost once the Eisenach factory was confiscated by the USSR on the Eastern side of the country (behind the Iron Curtain), the company starts making pots and pans, all sorts of cooking accessories, agricultural tools, brake pumps, light metal works, bikes and even spare parts for various mechanical tools and BMW cars. As you can imagine, the profits weren’t great so workers often were paid in the very products they were making for 8 hours a day

Therefore, between 1945 and 1947 BMW made no less than 34,000 pots which represented nearly a quarter of the revenue BMW made during those tough 24 months. As peculiar as it may seem, this chapter of BMW’s history might’ve not been glamorous or filled with revolutionary technologies but it carried the company forward, paving the road ahead and basically making it the giant that it is today.