Creating an eco-friendly car is not only about tailpipe emissions. You have to take into account all aspects of a car and a lot of people have been focusing on batteries lately, pointing them out as huge contributors to the overall carbon footprint a car has. BMW plans to cut that footprint massively in the future and the high-voltage battery will be among the key areas where improvements need to be done.

The Bavarian company announced today that it plans to reduce the carbon footprint of the batteries used in its future electric cars by more than half. At the moment, the process of manufacturing the battery and producing battery cells is extremely energy-intensive and therefore an important factor in the carbon footprint of any electric car.

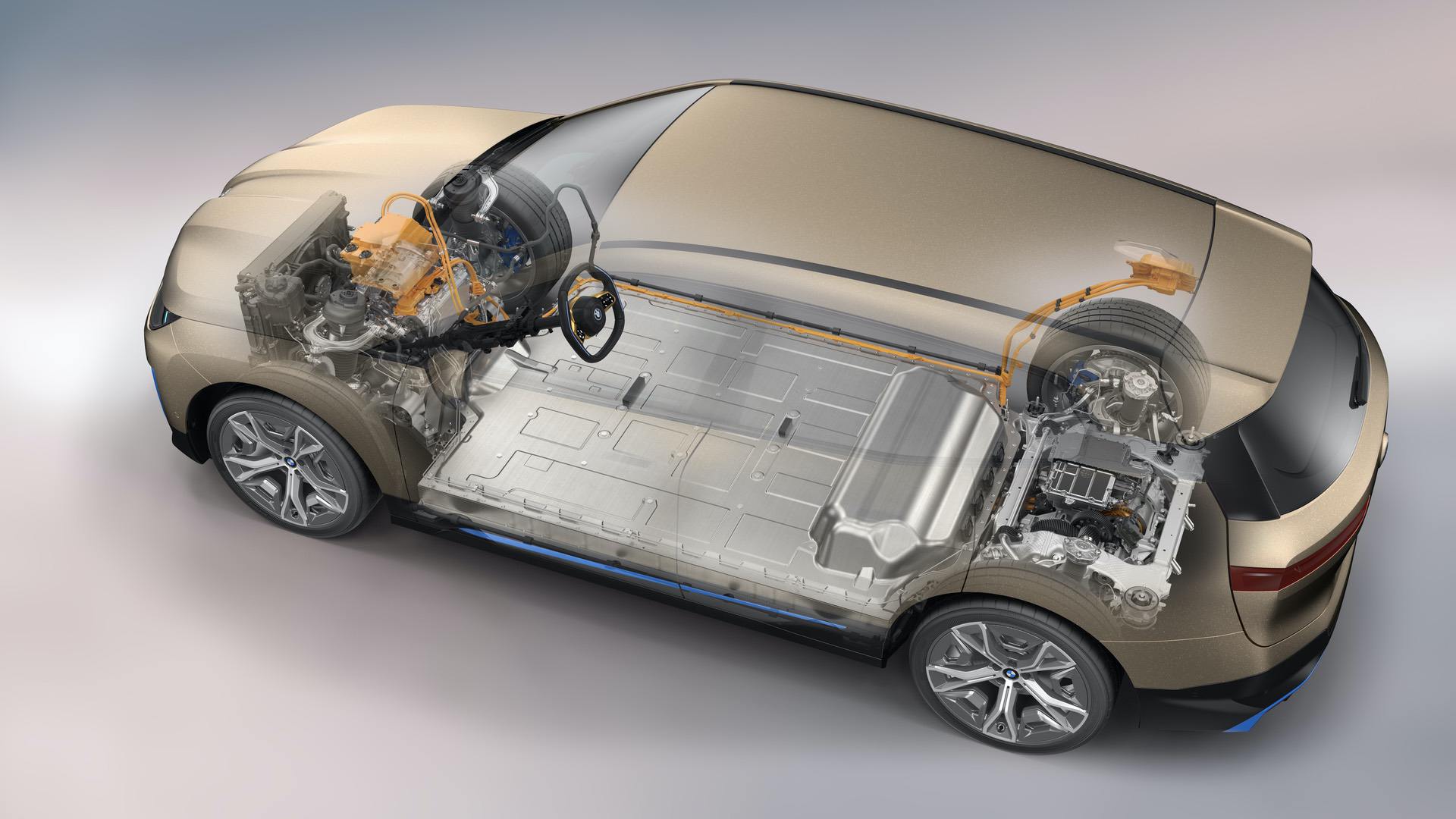

With the next generation of battery technology to be introduced in the “Neue Klasse”, the BMW Group aims to reduce the carbon footprint of the high-voltage battery to less than half the baseline value for the current Gen5 technology.

That’s not all though. In addition to the shift to green power already implemented by cell the cell manufacturers working with BMW (which are obligated to use renewable power sources in the production process), the new battery and cell concept, combined with enhanced cell chemistry, will also make a significant contribution. Another factor is the growing percentage of secondary material in the battery cells and high-voltage battery as a whole.

The housing in the BMW iX, for example, already contains up to 30 percent recycled aluminum and up to 50 percent recycled nickel, which is a key raw material, is used in the battery cell. At the same time, the BMW Group has limited its use of critical raw materials in the current generation of battery cells and reduced the amount of cobalt in the cathode material to less than ten percent. The electric motor no longer requires the use of rare earths right now and further improvements are to be made in the future.