After six years of design, engineering and testing, BMW’s flagship electric car is now ready for the world. The 2022 BMW iX will enter production in November before arriving in global markets next year. And what better place to test its capabilities other than the beautiful landlocked state of Bavaria.

The New BMW Flagship

Born in Munich, but manufactured in Dingolfing, the new iX electric crossover is as German as it can be. Yet the provincial German engineering DNA has been altered more than ever before. The BMW iX is an entirely new concept, built on an electric-first platform and with a new philosophy in mind: comfort over sportiness. Instead of building an X5-like vehicle with an all-electric drivetrain, BMW set out to create a new flagship model. In a way, the BMW iX is a trendsetter for the brand, just like the i3 and i8 were back in the day.

Of course, the iX has nothing in common with these cars when it comes to dimension or design, but it does inherit one fundamental idea: smart packaging and great freedom in designing the interior. At 4953mm in length, 1967mm in width and 1695mm in height, the BMW iX is just 31mm longer, 37mm narrower and 50mm lower than current BMW X5. Its wheelbase is also 8 mm longer than the popular SAV. Yet, BMW says that the iX will give the driver and passengers similar room as a 7 Series limousine. The cargo space is slightly smaller than in the X5 – 500-liter capacity or 1,750 liters if you lower the rear bench.

Purpose-Built Architecture

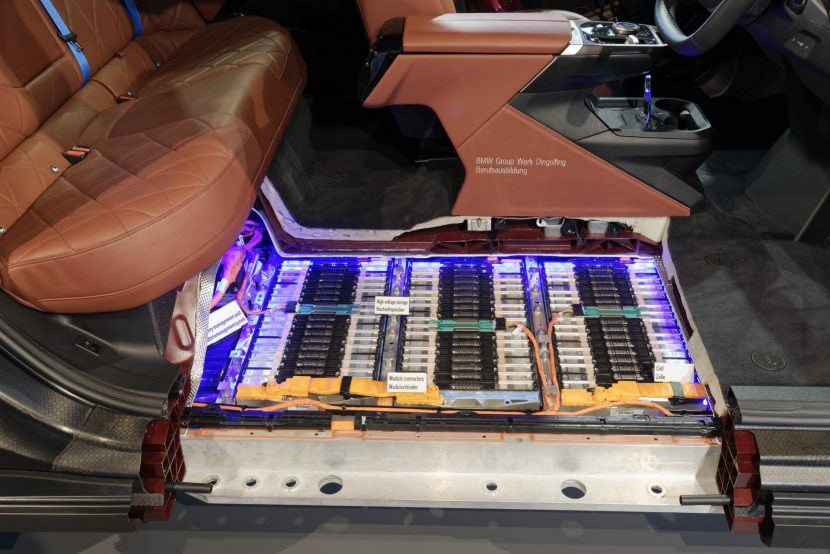

Having a dedicated electric vehicle platform means a few things. Firstly, it’s lighter than converting a traditional architecture over for an electric vehicle. The structural points and package requirements are designed specifically for a battery pack in the floor, electric motors at each axle, and the lack of traditional powertrain equipment. So there’s no waste in the chassis.

Secondly, as we mentioned earlier, the EV-first platform allows for better packaging, which in turn allows for better interior space, a larger battery pack, and more cargo space. Lastly, it gives BMW designers more freedom to design the car as they want, as there are fewer powertrain packaging constraints to worry about. There are other tricks at play here too. For example, the car’s design was made this way to keep the drag coefficient as low as possible and the iX is a record holder in this regard, with 0.25 cd.

For instance, the completely flat rear trunk floor in the iX is only possible because it doesn’t have a traditional transmission tunnel to work around. The battery can be stored completely flat underneath the floor with no obstructions. Therefore, the battery is packaged better and rear passengers have far more foot room. Also, because the rear subframes and suspension were designed for an electric motor, the entire eDrive unit can be stored under the rear trunk floor with no intrusion into cargo space.

The BMW iX also makes clever use of materials in its chassis. Some of the chassis’ lower half is made from CFRP (carbon fiber reinforced plastic), which helps reduce weight and add stiffness.