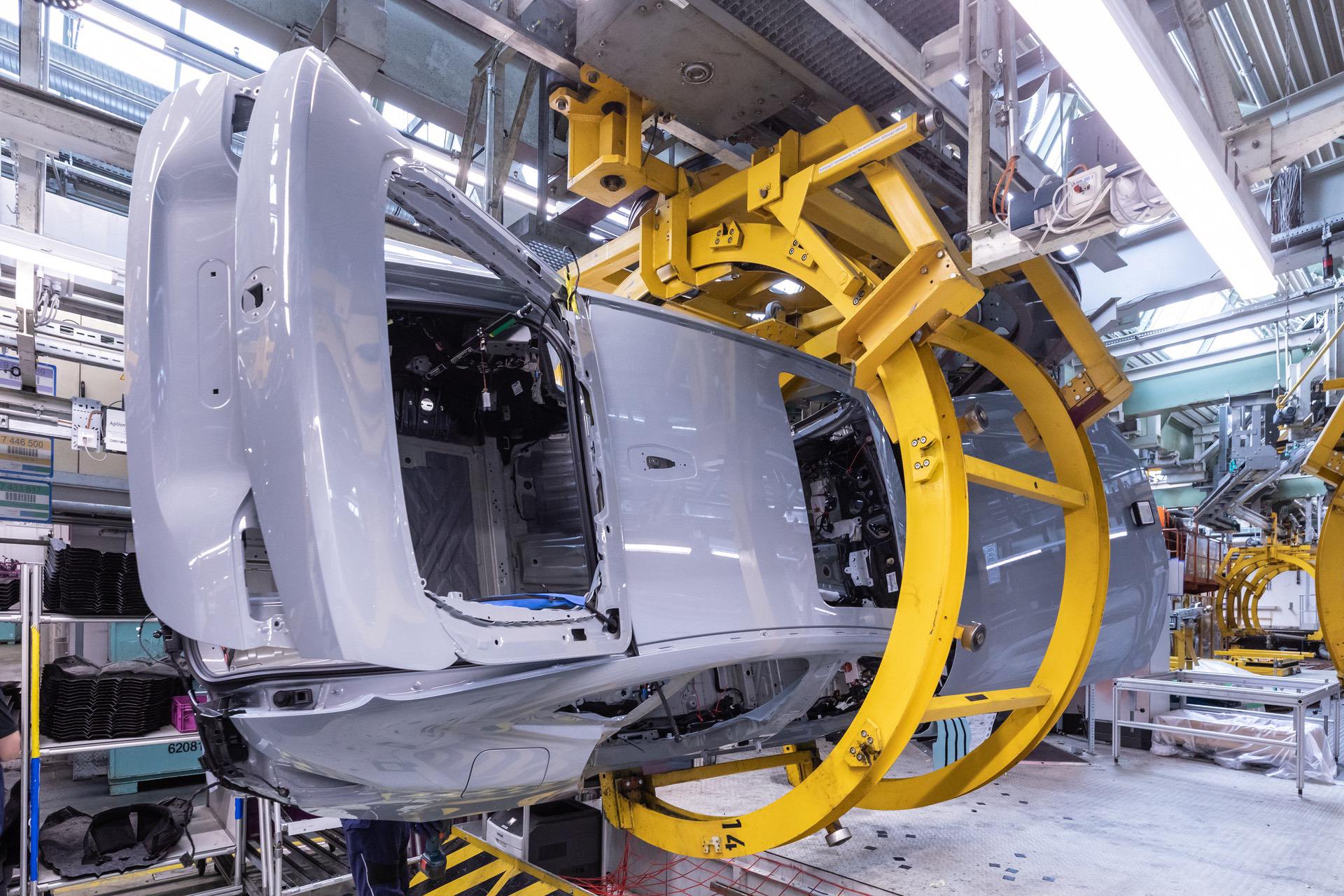

Today is a big day at the BMW plant in Munich, as the first-ever BMW i4 rolled off the production line. The Munich plant is almost 100 years old, so seeing the all-electric i4 finish production there is a big deal for BMW. Its production also kicks off the future for the brand, as BMW has no intentions of slowing down its efforts into electrification.

“For the plant and team, the launch of the BMW i4 is a milestone on the road to electric mobility,” said Milan Nedeljković, BMW AG Board Member for Production. “By 2023 more than half of all vehicles from our Munich facility will have an electrified drive. The majority will be fully electric. So Munich goes fully electric.”

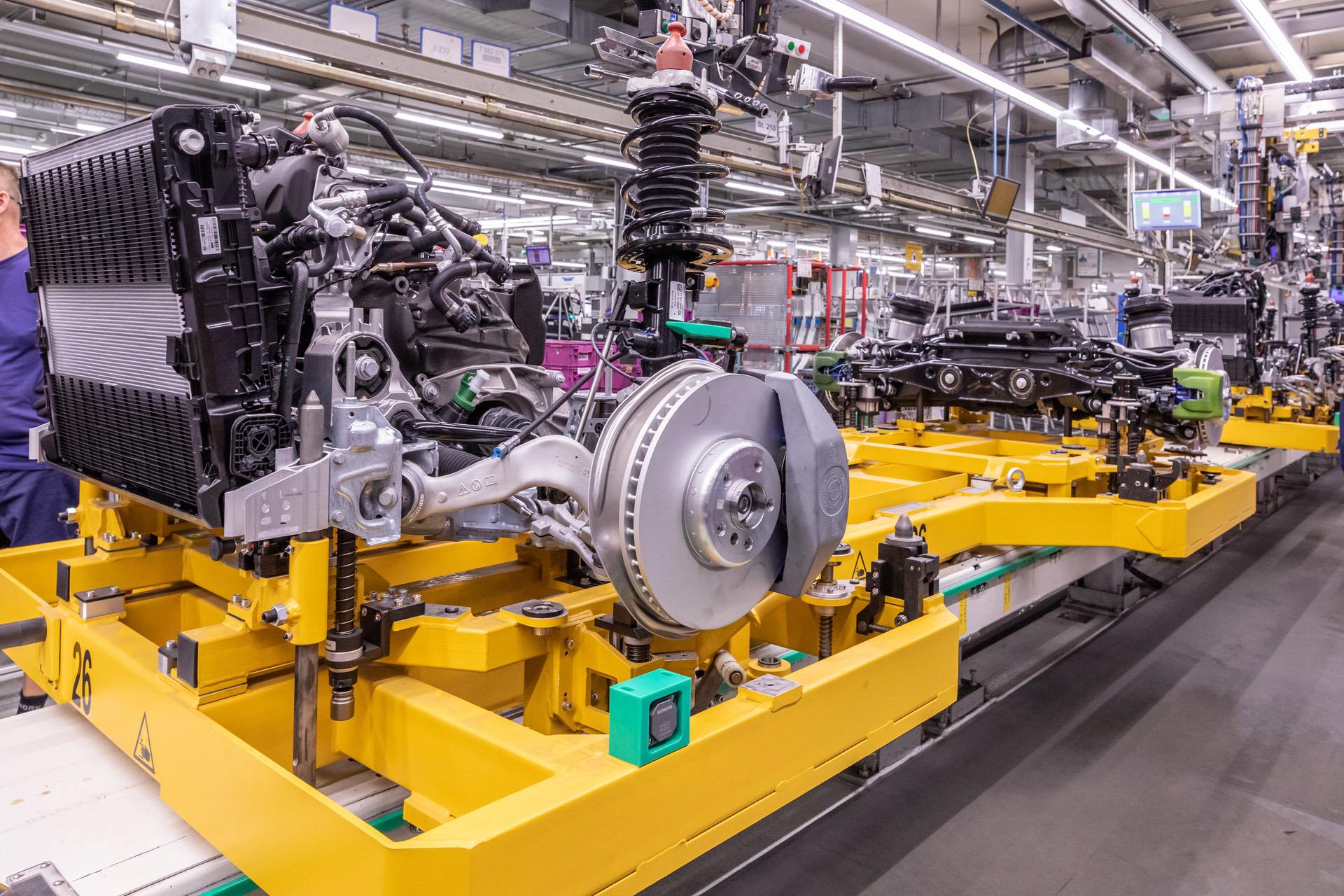

BMW went to great lengths to prepare the nearly century-old plant for the production of a fully electric vehicle. Especially when you consider that the Munich plant also has to continue building internal combustion vehicles as well. Alongside the i4, cars like the BMW 3 Series, 4 Series Gran Coupe, and even the BMW M3.

“We succeeded in integrating the new vehicle into our existing systems without halting production. The team and our partners did an amazing job,” said Peter Weber, Director of BMW Group Plant Munich.

BMW’s Munich plant is also one of the most high-tech manufacturing facilities in the industry. The entirety of the facility is currently being 3D scanned (a process that was completed for both the Spartanburg and Regensburg plants). The 3D scans will help create a digital database for the plant that can be cloud-shared from anywhere in the world to help with additional manufacturing.

It’s not only an efficient, high-tech plant, it’s also a sustainable one. BMW is now using reverse osmosis for the water used in certain manufacturing processes, such as the cathodic dip – where the base coat is applied to vehicles – to reuse the water. This is said to reduce fresh water consumption by more than six million liters per year. BMW is also reducing its CO2 emissions, by increasing the amount of battery electric vehicles used in its transport trucks and rail systems. The endgame is for all transport vehicles leaving the Munich plant to be zero-emission vehicles.

“We are well aware that, owing to the city location of our production facility, we have a special responsibility. Our project to reduce CO2 emissions at our home plant will have a major impact that’s positive both for the environment and for our immediate neighborhood.” said Weber.

It cost BMW €200 million to revamp the Munich plant for BMW i4 production but it’s a worthwhile investment. The i4 is the beginning of BMW’s future and the fact that it’s built in the century-old Munich facility is fitting.