BMW won’t end production of the i3 hatchback until next month but it’s already assembling a namesake car in China. Officially revealed earlier this year, the i3 eDrive35L is a purely electric version of the 3 Series Sedan LCI, based on the long-wheelbase model. The BMW Group has bolstered its manufacturing footprint in the People’s Republic with the opening of the Plant Lydia in Shenyang where the new i3 is assembled.

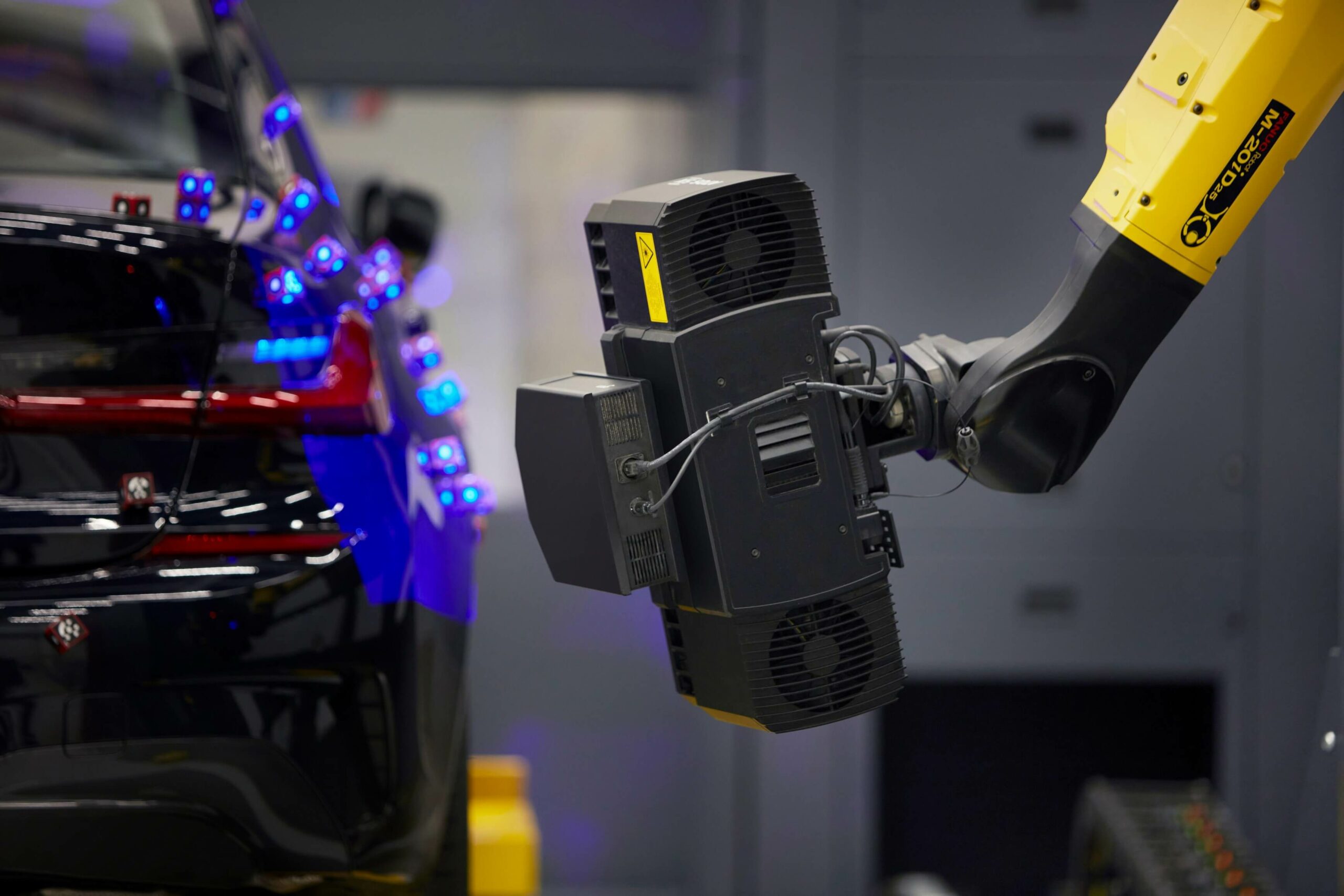

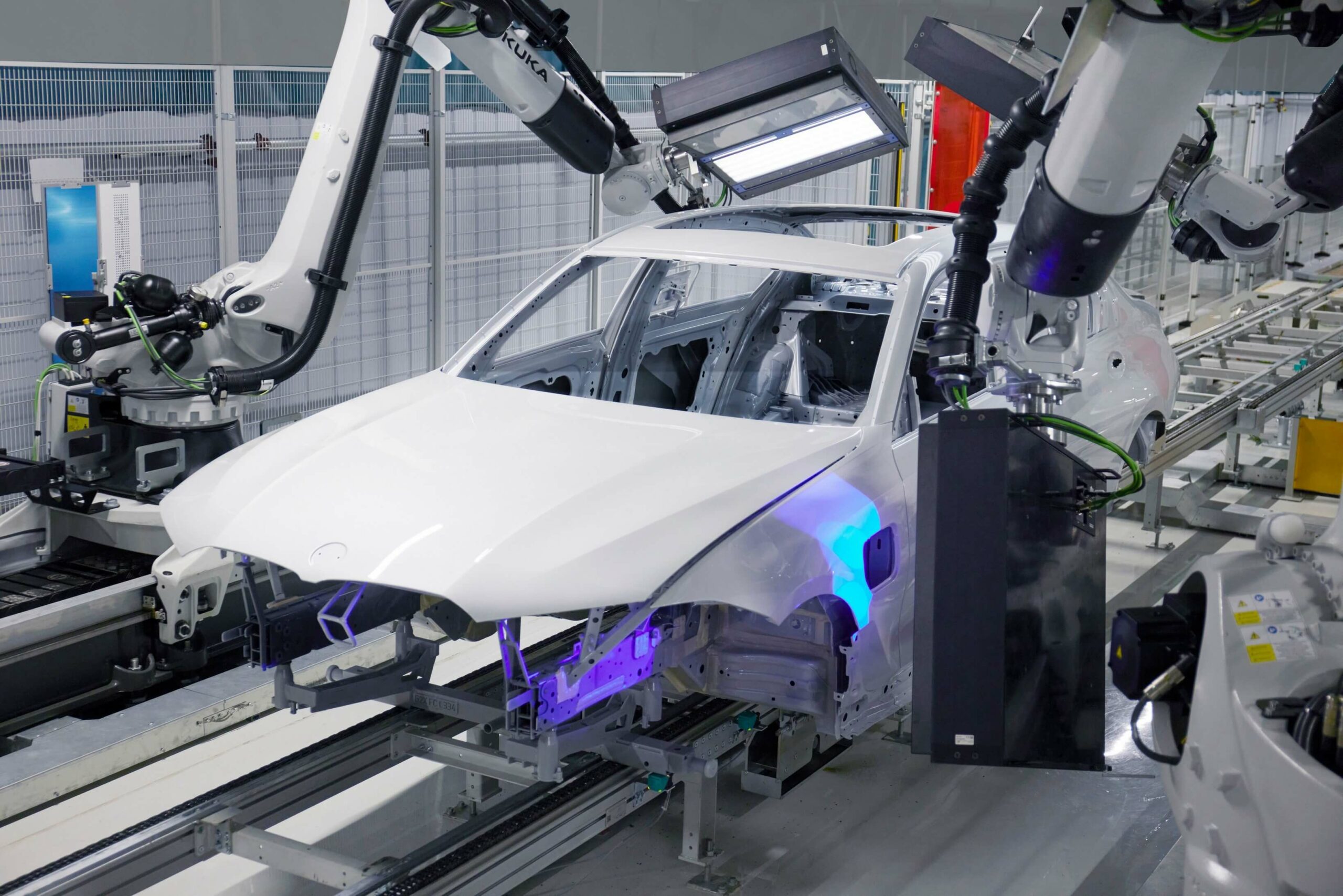

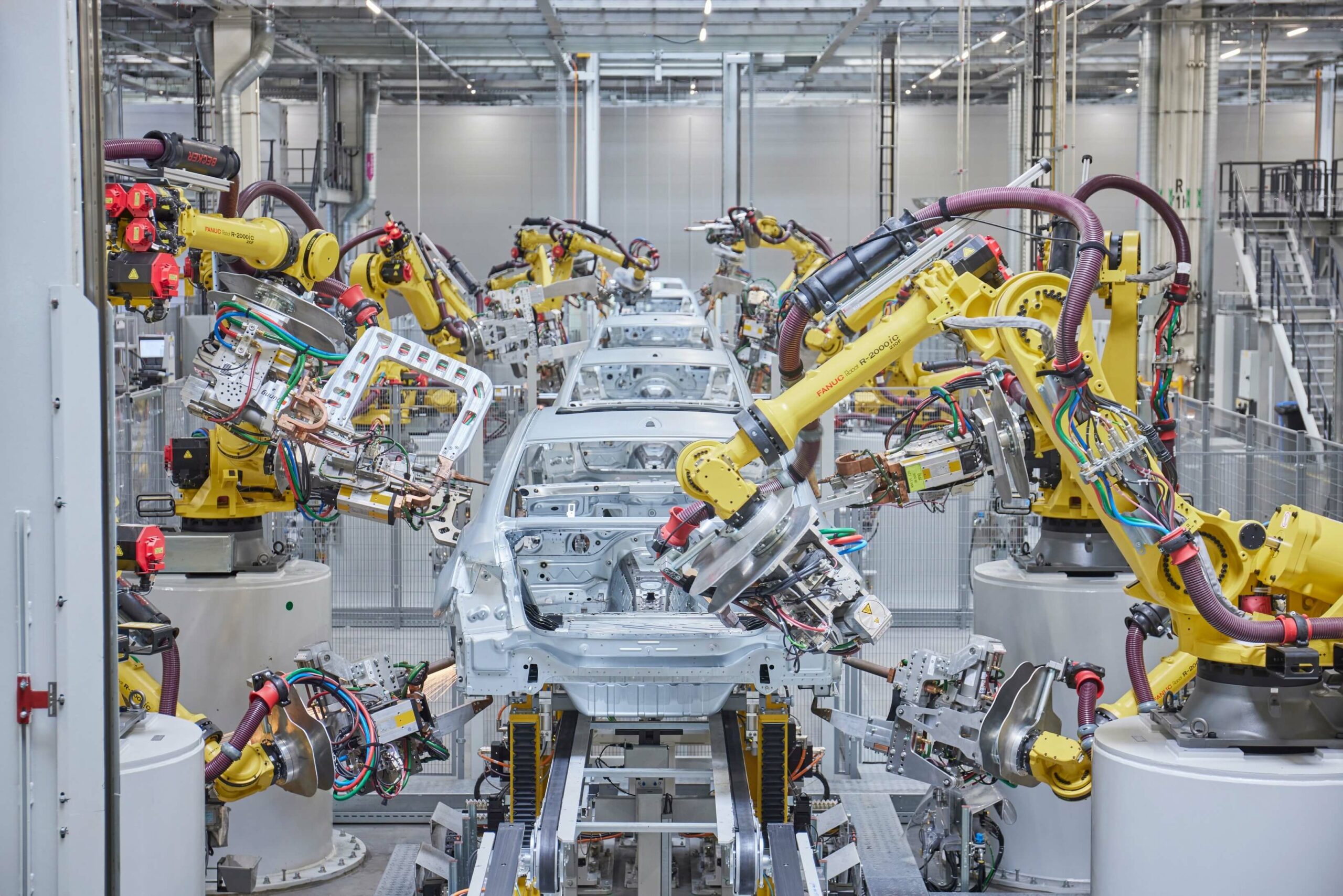

The automotive conglomerate has spent RMB 15 billion (about $2.2 billion) at Plant Lydia, representing the largest single investment ever made by BMW Group in China. The factory has been conceived from day one to be flexible enough to produce up to 100% electric vehicles should the market demands require it.

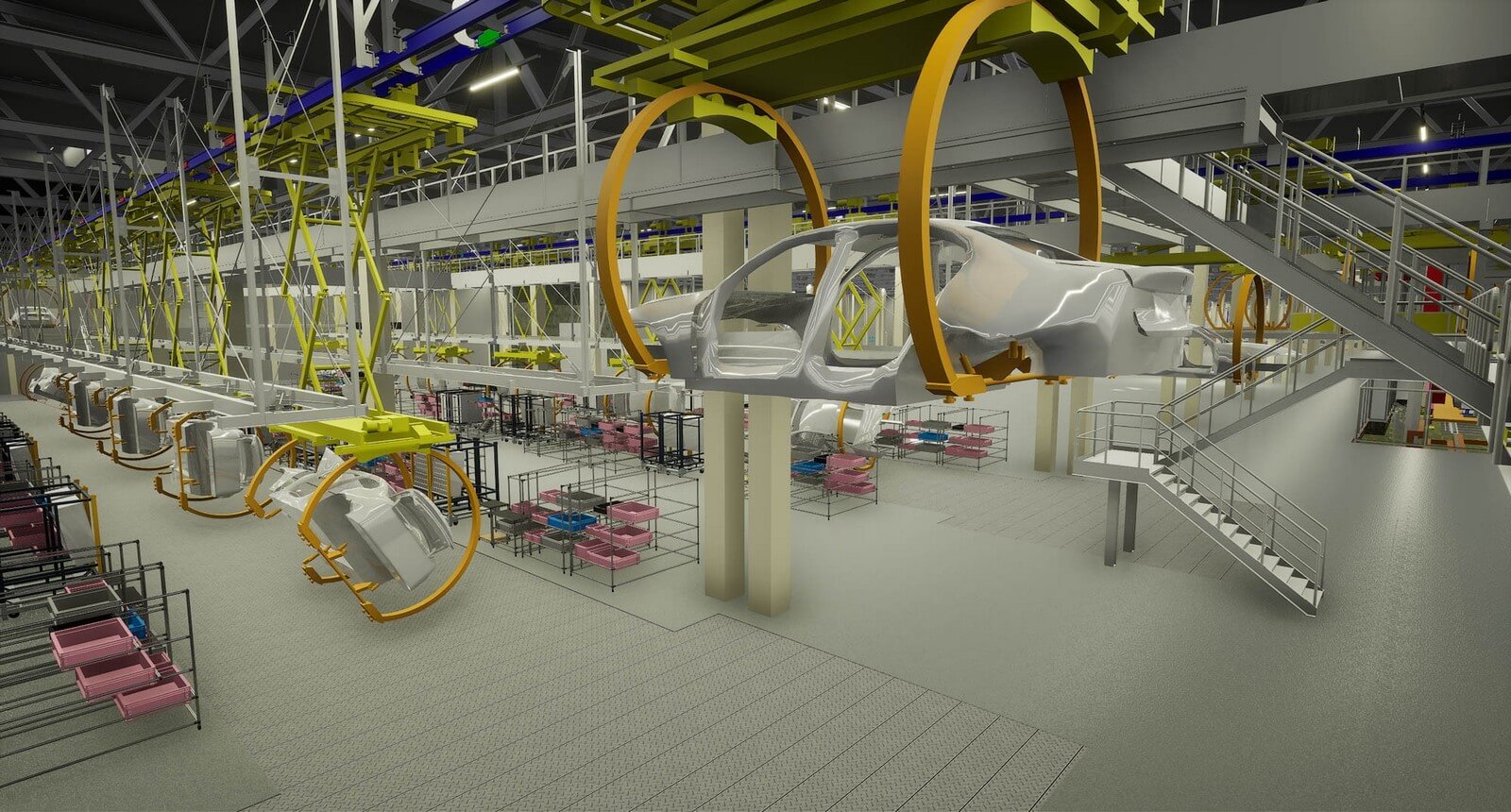

The new plant helps the company expand its annual production capacity in the Shenyang region to 830,000 cars, including the vehicles assembled at the neighboring factories in Tiexi and Dadong. Aside from the assembly facility itself, Plant Lydia also encompasses a press and body shop as well as a paint shop.

For those who are unfamiliar with China’s i3, the zero-emissions sedan is sold exclusively with a rear-wheel-drive layout courtesy of a single electric motor mounted at the back. It will go down in history as the first 3 Series with air suspension, albeit it’s only for the rear axle. The EV rides 44 millimeters (1.73 inches) lower to the ground and utilizes a battery pack with a net capacity of 66.1 kWh (70.3 kWh gross) to cover 526 kilometers (327 miles) in the regional CLTC test cycle.

With 282 hp (210 kW) and 400 Nm (295 lb-ft) at the driver’s disposal, the BMW i3 eDrive35L needs 6.2 seconds to hit 62 mph (100 km/h). It’s worth noting practicality has taken a hit as the extra hardware commanded by the EV setup eats into trunk’s cargo capacity, which has been reduced by 70 liters to 410.

As a final note, BMW also makes the RWD-only iX3 in China, but unlike the i3 sedan, the electric crossover is exported to other countries.

Source: BMW