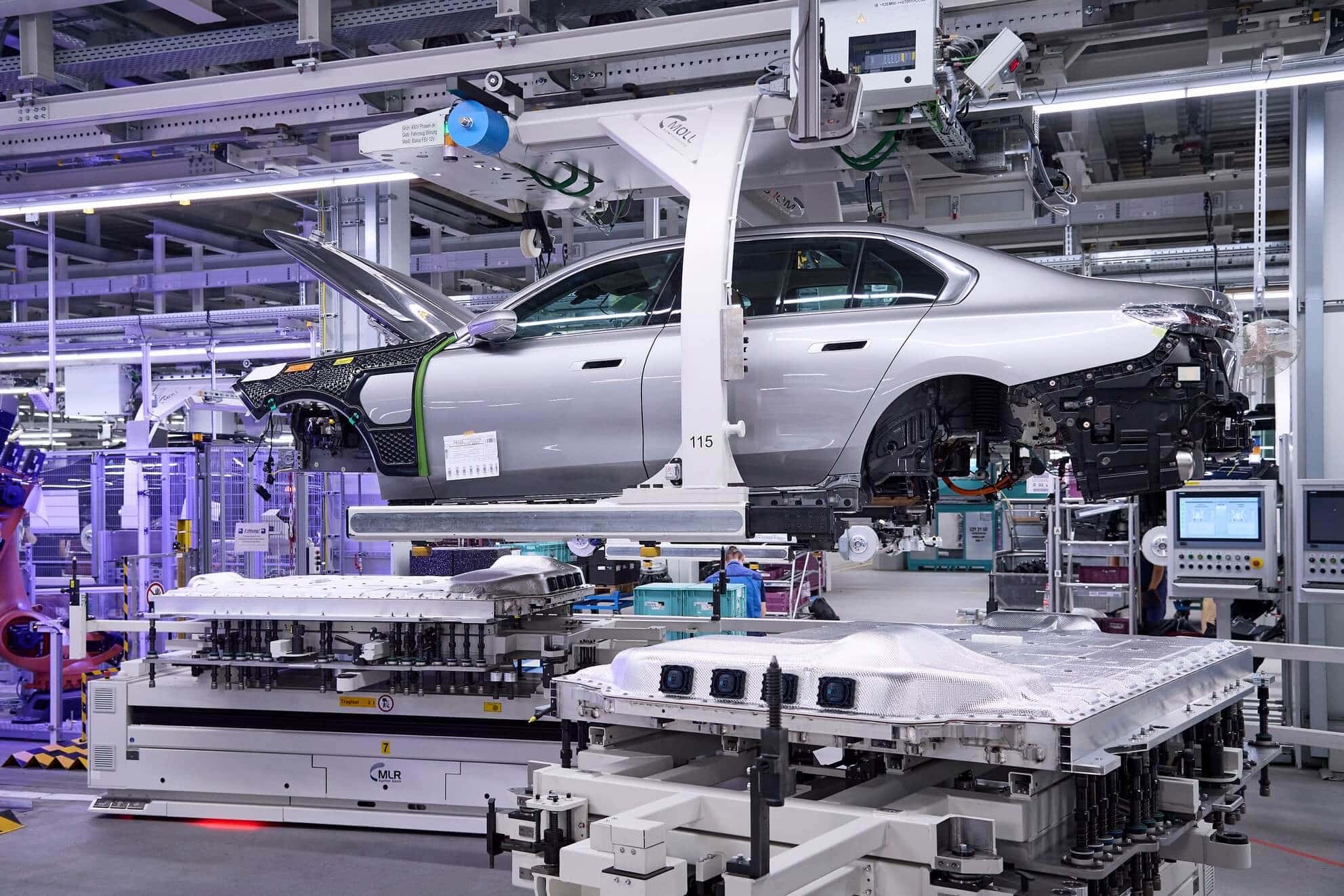

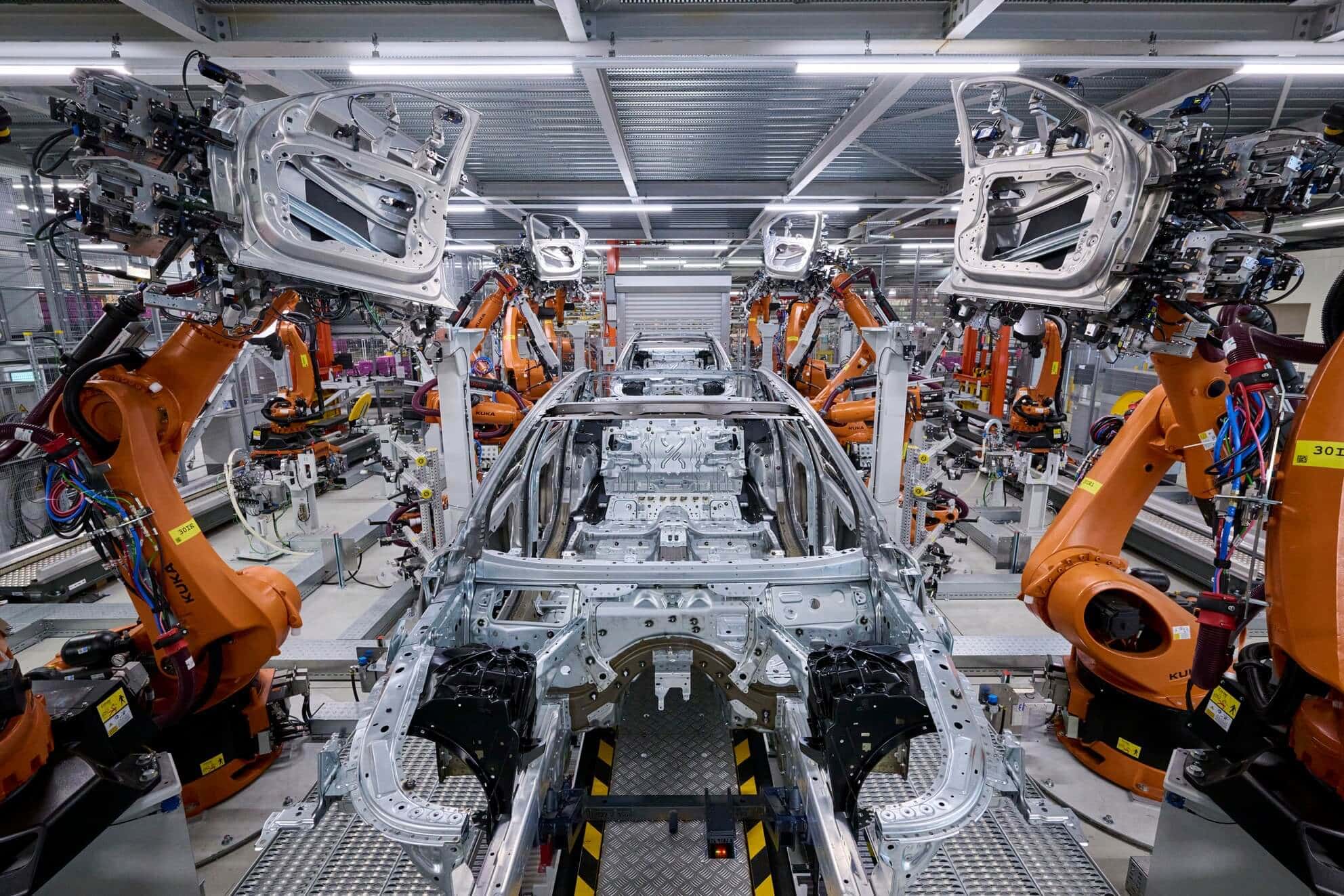

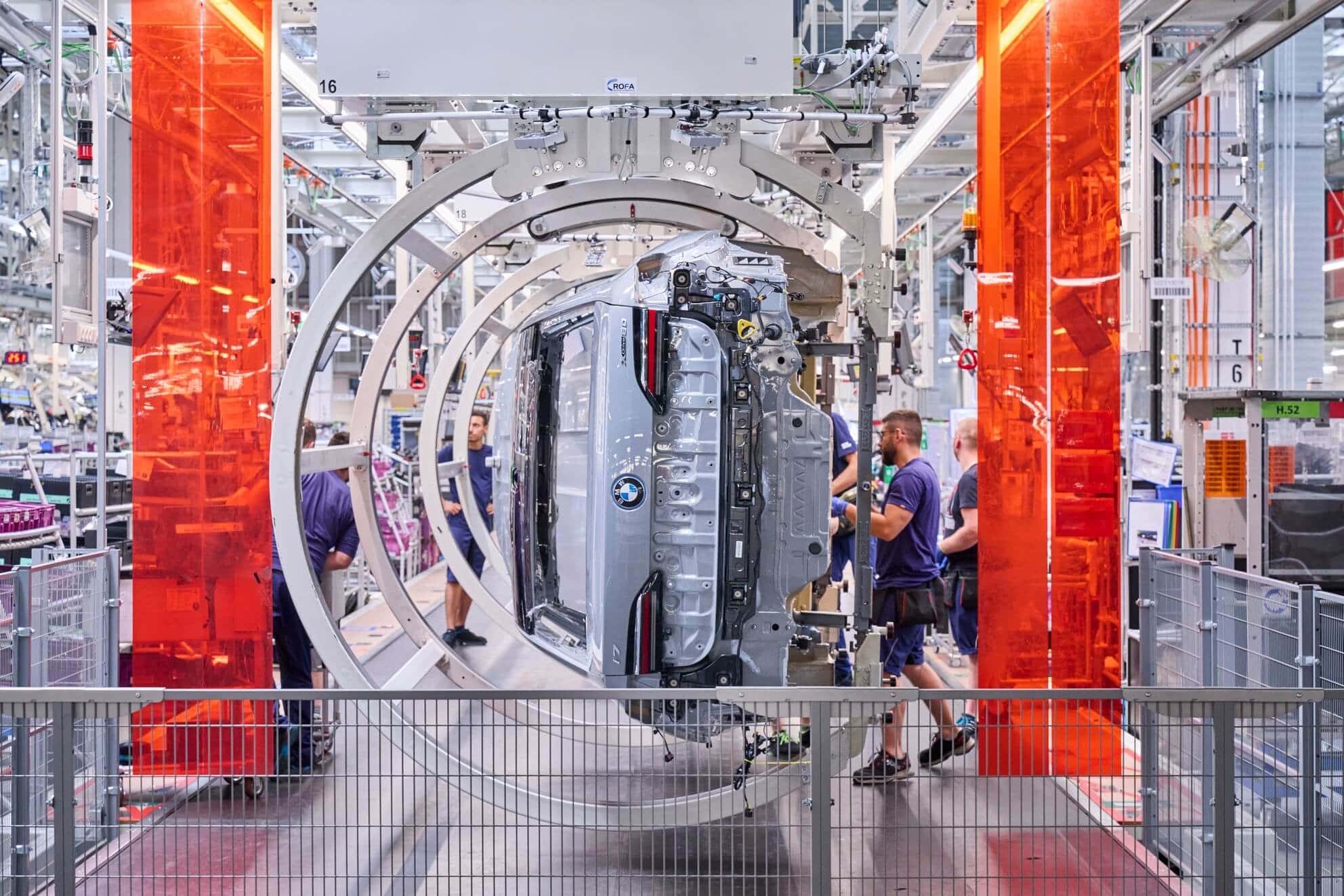

Right on schedule, BMW has commenced series production of the seventh-generation 7 Series at the Dingolfing factory. The G70 is now rolling off the assembly line with both combustion engines and electric drivetrains as the gasoline- and diesel-fueled 7er is joined by the first-ever i7. The German automotive conglomerate has spent more than €300 million to get the plant ready for the all-new flagship sedan.

The fullsize luxury saloon is being put together on the same line as the 5 Series, 8 Series, and the iX. By the middle of the decade, BMW estimates half of the vehicles it will build in Dingolfing will be electric. Speaking of which, the large zero-emissions SUV entered production at the factory exactly a year ago and the 7 Series uses some product and process modules that were initially developed for the iX.

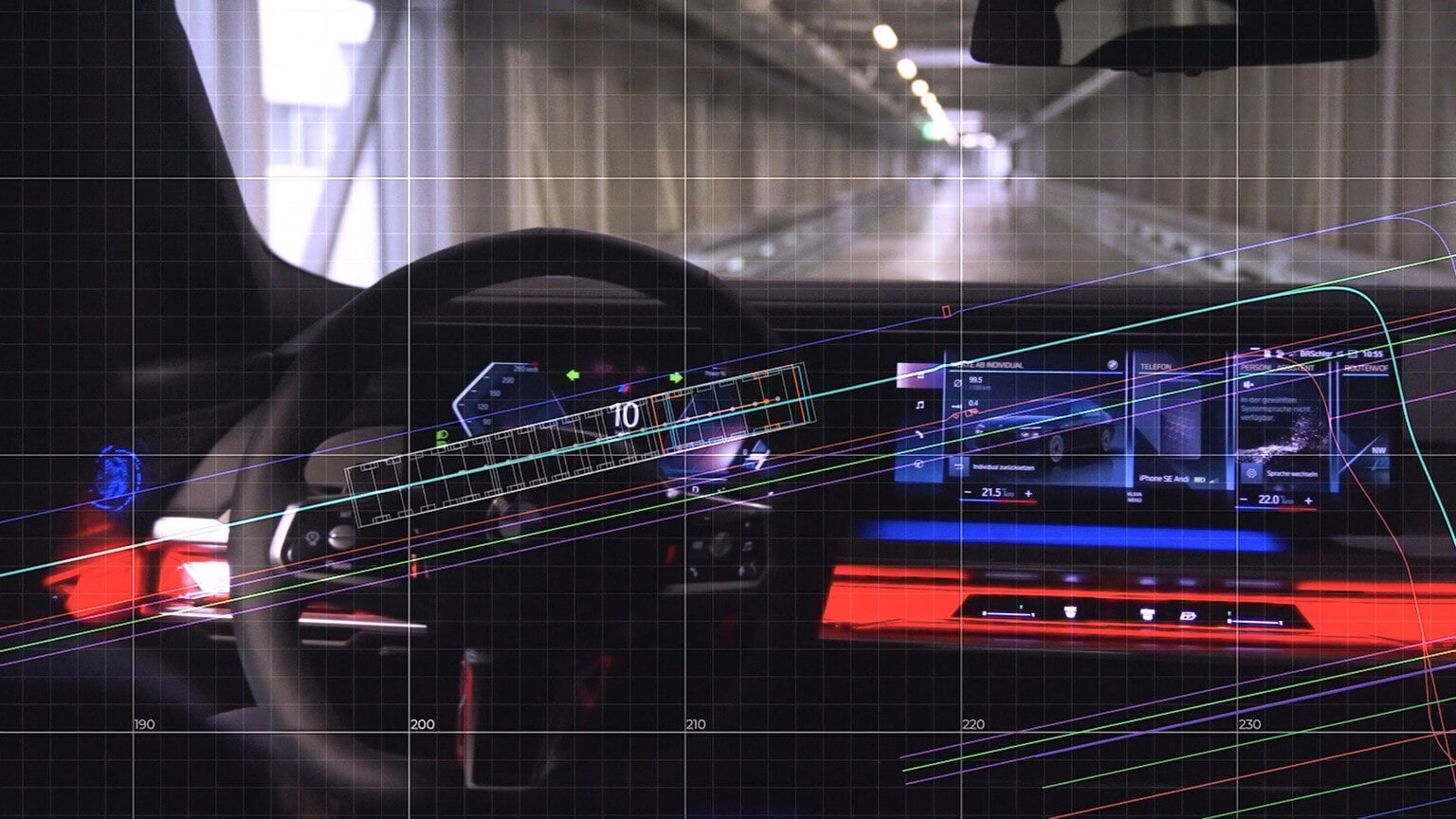

Getting back to the 7 Series at hand, it’s the first M Performance model from BMW to come with a plug-in hybrid powertrain. The M760e combines an inline-six gasoline engine with an electric motor for a total output of 571 horsepower. However, it’s not the most potent 7er money can buy since the i7 M70 arriving next year will have a whopping 660 of electric horses.

Dingolfing is responsible for the i7 xDrive60’s electric motors and battery pack as these are also produced where the cars are made. At the same facility, BMW also builds the high-voltage battery and highly integrated electric drive for the iX3 (as well as i4 and iX) even though the vehicle itself is assembled in China.

BMW is just getting started with its electric onslaught since the i5 will follow in 2023, with reports stating an i5 Touring is not far behind. Further down the line, the Neue Klasse platform will serve as a foundation for an i3 in both sedan and wagon flavors. In the meantime, the company bid adieu this week to the original i3 hatchback, which was produced in a little over 250,000 examples during its nine-year life cycle.

Source: BMW