In February, I had the rare opportunity to witness firsthand one of the most ambitious transformations in BMW’s history. Hidden behind the brand’s iconic headquarters and museum, the Munich plant is undergoing a massive modernization effort that will completely reshape how BMW builds cars in the heart of its hometown. This factory—one of BMW’s longest-running production sites—has been in operation since 1922, and by 2027, it will produce only fully electric vehicles, making it one of the company’s first plants dedicated entirely to Neue Klasse production.

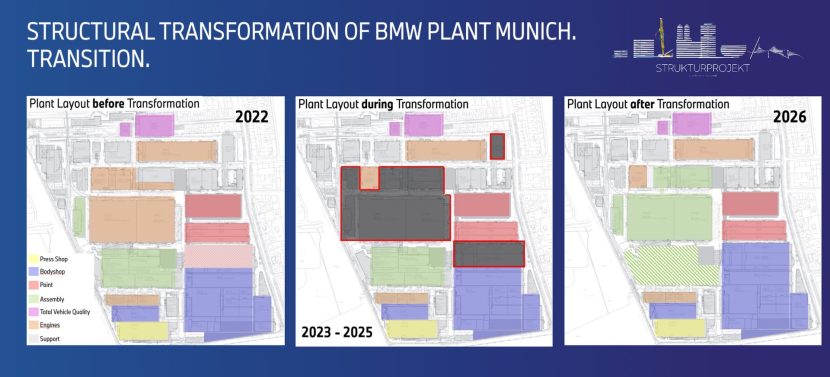

Unlike BMW’s brand-new factory in Debrecen, Hungary, which was designed from the ground up for the Neue Klasse EV platform, the Munich facility must be rebuilt from within, while maintaining full-scale production. The challenge is enormous: BMW is tearing down and rebuilding one-third of the entire plant without stopping production. Every day, 1,000 cars roll off the line while cranes, trucks, and workers operate around them. The factory is not expanding outward due to space limitations—it is growing vertically, with three-story production buildings replacing older structures.

“We are not transforming this plant just because we are transitioning to electric vehicles. The plant can already produce electric cars, like the i4, which makes up 40% of its current production. The reconfiguration is happening because the plant is 100 years old. From time to time, you have to rethink production and develop a new structure,” explained Dr. Mohan Noronha, Project Lead for the Structural Transformation of BMW Factory Munich.

Building a New Factory While Keeping the Old One Running

The transformation of the Munich plant is not just about introducing new technology—it is about doing so while keeping the factory operational. Unlike many automotive plants that shut down for extensive retooling, BMW has no such luxury here. The city’s dense urban environment makes large-scale expansion impossible, so the automaker is demolishing and rebuilding sections of the factory in phases while production continues.

This process requires careful planning and precise logistics. BMW has initiated 13 major relocation projects to clear space for the new structures. Entire departments, including engine production, wastewater treatment, and axle pre-assembly, have been moved to other locations to make way for the new assembly lines. The engine manufacturing division has been relocated to Austria and the UK, marking the end of combustion engine production in Munich.

With these massive shifts, 600,000 tons of material must be dismantled, tested, and either disposed of or repurposed. Regulations require BMW to analyze and process this material before moving it off-site, meaning large portions of the factory grounds must be used for temporary storage. Meanwhile, 400 trucks move in and out of the plant every single day, delivering parts for production and hauling away dismantled structures.

New, More Energy Efficient Buildings

When completed, the transformation will introduce 70,000 square meters of new production floor space, making the plant more efficient and better suited for EV manufacturing. Three new production buildings are being constructed for assembly and body shop operations, each with three full stories to optimize floor space. These new structures will be 40% more energy efficient than the ones they replace, aligning with BMW’s broader sustainability goals.

“We had to rethink everything. There’s no room to expand outward, so we’re building vertically. The new Final Assembly Hall has three floors, each nine meters high—the footprint alone is the size of six football fields. And when you step inside, you realize just how fast things are changing. If you leave for two weeks and come back, new walls have already gone up,” Dr. Noronha told us during our visit.

Technology, AI, and Workforce Transformation

Beyond its structural changes, the Munich plant is also adopting new technology to streamline production. The new body shop will integrate 900+ robots, significantly reducing the need for manual labor in welding and assembly processes. AI-powered quality control systems will inspect vehicles in real-time, minimizing defects and improving efficiency. Additionally, automated logistics systems will replace traditional forklifts, reducing human labor in parts transportation.

Despite this shift toward automation, BMW is not reducing its workforce. The plant currently employs 6,500 people from over 60 nationalities, and instead of layoffs, BMW is retraining and repositioning employees for new roles in EV production. A new Talent Campus is being built to provide continuous training, ensuring that employees remain at the forefront of modern automotive manufacturing.

“We are not reducing jobs; we are training our people for the future,” said Dr. Noronha.

Sustainability and the Future of Urban Manufacturing

The transformation is also driven by sustainability and community integration. Given the factory’s location in the heart of Munich, BMW has committed to reducing emissions, noise, and traffic congestion while improving the plant’s visual and environmental footprint. The new design incorporates green spaces, and BMW is exploring ways to make parts of the factory more accessible to the public.

Additionally, logistics are being optimized to minimize unnecessary transportation, with parts being delivered directly to production lines instead of passing through multiple locations. These efforts will reduce traffic around the plant and lower emissions, making the facility more compatible with the surrounding urban environment.

An Impressive Achievement in Just a Year

Walking through the plant, it was clear—this isn’t just a simple factory upgrade. This is a historic transformation. For over a century, BMW’s Munich plant has been the beating heart of the brand’s manufacturing. Now, it is evolving into a state-of-the-art EV production hub, setting the stage for the Neue Klasse models that will define BMW’s future.

The most remarkable part? BMW is doing all of this without stopping.