The BMW Group showcases its visions of future mobility in the shape of the BMW i3 Concept and BMW i8 Concept studies. Unveiled for the first time, these concept vehicles provide a glimpse of the first electrically powered production cars from the new BMW i sub-brand, due to be launched as the BMW i3 in 2013 and the BMW i8 in 2014.

“We are marking another milestone in the history of the BMW Group. As Chairman of the Board and an engineer myself, I am very proud of this project,” declared Norbert Reithofer, Chairman of the Board of Management of BMW AG, at Friday’s premiere of the two vehicles in Frankfurt. “As the world’s leading premium car manufacturer, our aim is to offer customers purpose-built electric-drive cars as well,” he added.

With its zero-emission electric drive and a range of approximately 150 kilometres, the BMW i3 Concept has been specifically developed for use in an urban environment, its dynamic 125 kW electric motor and rear-wheel drive ensuring BMW-style dynamic handling. Thanks to its innovative LifeDrive architecture featuring a carbon passenger cell, the BMW i3 Concept combines an extremely low weight of 1,250 kilograms with optimal interior space and the highest crash safety levels. With four seats and a 200-litre luggage compartment, this vehicle is fully suited for everyday use.

Draeger: a revolution in car design

“This vehicle will mark the launch of the first volume-produced car featuring bodywork largely made of carbon. It’s a revolution in automotive design,” stressed Klaus Draeger, Member of the Board responsible for Development. The application of this new CFRP technology allows a weight reduction, compared to a conventional electric car, of between 250 and 350 kilos, and that means more dynamic handling coupled with a greater range. The BMW i3 does the 0 to 100 km/h sprint in less than eight seconds, while a high-speed charger achieves an 80% battery charge in just an hour.

Thanks to the emission-free drivetrain and a value added chain designed to be sustainable all along the line, life cycle emission figures for the BMW i3 are at least a third lower than for a highly efficient combustion-engine car. If the BMW i3 is run on electricity from renewable sources, the figures improve by well over 50%.

BMW i8 Concept: new-generation sports car

The BMW i8 Concept goes from 0 to 100 km/h in less than five seconds and boasts fuel consumption of under three litres per 100 km. Its plug-in hybrid drive with a system output of 260 kW allows a range of up to 35 kilometres in electric mode – sufficient for most everyday journeys. For more dynamic driving or out-of-town routes, a high-performance three-cylinder petrol engine also comes into play. The sports car has an electronically governed top speed of 250 km/h and space for up to four occupants. “The BMW i8 Concept is the sports car for a new generation – pure, emotional and sustainable,” Draeger underlined.

With BMW i, the BMW Group is corroborating its position as the most innovative and sustainable auto manufacturer in the world, as reflected in the fact that it has been the supersector leader in the Dow Jones Sustainability Indexes for the sixth year running. With BMW i, the BMW Group is providing answers to the mobility challenges of the future while pursuing a holistic approach. In addition to purpose-built premium vehicles with electric drive, the company is also offering intelligent mobility services.

The focus here is on solutions for improved use of parking space, intelligent navigation systems with location-based information, intermodal route planning and car-sharing schemes such as DriveNow. Following MyCityWay, ParkatmyHouse marks the second investment by the recently launched venture capital company BMW i Ventures in a company providing internet-based mobility services. Parkatmyhouse allows private individuals to use the internet or a smartphone app to rent out their private parking spaces on a short- or long-term basis.

Both the BMW i3 and the BMW i8 will be built at BMW’s Leipzig plant in Germany. Some 400 million euros are earmarked for investment in new buildings and facilities by 2013, while 800 new jobs are to be created. Vehicle production will be CO2 neutral and will draw on renewable resources. The company is currently investigating the possibility of erecting its own wind turbines on the plant site.

Full Press Release:

The world, and with it the sphere of personal mobility, is experiencing a period of radical environmental, economic and social change. A rash of global developments such as climate change, the dwindling availability of resources and increasing urbanisation call for a new balance between the demands of the planet and the desires of the individual. Fresh solutions are required to underpin personal and, most importantly, sustainable mobility. The BMW Group has responded to this situation with the creation of a sub-brand which meets the changing needs of customers head-on: BMW i.

BMW i is about the development of visionary vehicles and mobility services, inspiring design, and a new understanding of premium that is strongly defined by sustainability. With BMW i the BMW Group is adopting an all-embracing approach, redefining the understanding of personal mobility with purpose-built vehicle concepts, a focus on sustainability throughout the value chain and a range of complementary mobility services. In so doing, BMW i is also opening up new target groups for BMW and further strengthening the position of its parent company as a sustainable and future-oriented brand.

“The purpose-oriented and sustainable mobility solutions from BMW i mark the dawn of a new era in personal mobility for the automotive industry.” (Ian Robertson, member of the Board of Management of BMW AG responsible for Sales and Marketing) project i – how BMW i was born.

The BMW i brand world comprises vehicles and services developed since 2007 as part of project i, a BMW Group think tank set up to explore sustainable mobility solutions. Launched under the banner of the corporate strategy Number ONE, project i was charged with developing sustainable and pioneering mobility concepts. The intention of the initiative was always to generate a transfer of expertise into both the company as a whole and future vehicle projects specifically. The overriding goal of project i is to preserve the BMW Group’s position as the leading supplier of premium products and services for personal mobility in the future as well. To this end, the development engineers involved have always focused their attentions on the entire value chain. After all, it is not only the products of the future that should be sustainable; every parts-related process, every technology and every supplier is required to contribute to the positive sustainability rating of the products.

As part of project i the BMW Group is currently conducting field trials in everyday conditions with vehicles running purely on electric power. These trials are unparalleled worldwide in their scope. The ongoing trials in the USA and Europe with a fleet of more than 600 MINI E cars are already delivering important feedback on the demands the series-produced electric vehicles of the future will need to meet. Added to which, a test fleet of over 1,000 BMW ActiveE vehicles – set for launch in the USA, Europe and China at the end of 2011 – will contribute valuable insights into the performance of these models in everyday use. The information gained will serve to deepen the existing knowledge base on the everyday use of vehicles with electric drive systems and to find out more about what customers want and need. Feedback from the customers trialling the MINI E and BMW ActiveE is channelled directly into the series development of the BMW i vehicles.

Two special vehicle concepts.

The BMW i brand is now poised to enter the consciousness of the automotive public with two new vehicles. First up is the BMW i3 Concept. Previously known as the Megacity Vehicle, the BMW Group’s first series-produced all-electric car focuses squarely on the mobility challenges of the future in urban areas and, as the first premium electric vehicle, reinvents hallmark BMW attributes for the drivers of the future. Then comes the BMW i8 Concept, a sports car of the most contemporary variety – forward-looking, intelligent and innovative. Based on the BMW Vision EfficientDynamics concept car, its unique plug-in hybrid solution brings together a combustion engine and an electric drive system to create an extraordinary driving experience complemented by extremely low fuel consumption and emissions.

BMW i3 Concept – dynamic, compact, emission-free.

The BMW i3 Concept is an uncompromisingly sustainable vehicle designed for urban areas. Driven purely by electric power and purpose-built to meet the demands of sustainable and emission-free mobility, it embodies an intelligent form of urban transportation and commuting.

“This automotive concept uses a new architecture which showcases all of its new possibilities and potential. It is the world’s first premium electric vehicle.” (Andreas Feist, Head of vehicle project BMW i3)

The BMW i3 is a well-resolved all-round concept, with every detail conceived and optimised to fulfil its eventual purpose. Central to its design is the innovative LifeDrive architecture, the key to the BMW i3 Concept’s appeal as a light, safe and spacious car. Innovative use of materials and intelligent lightweight design not only enable the i3 Concept to travel long distances on a single charge and provide superb safety in the event of a collision, they also help give the car its excellent driving dynamics. The secure arrangement of the battery in the Drive module gives the vehicle a very low centre of gravity and optimum weight distribution. The electric motor over the rear axle – which generates output of 125 kW/170 hp and impressive torque of 250 Nm (184 lb-ft) from a standstill – and a small turning circle combine to deliver pleasingly crisp driving characteristics and give the driver a very immediate experience of the BMW i3 Concept’s lightweight design. The BMW i3 Concept accelerates from 0 to 60 km/h (37 mph) in under four seconds and from rest to 100 km/h (62 mph) in less than eight seconds. The extremely direct sensation at the wheel is expressed in outstanding agility at low speeds and during turning manoeuvres, and makes parking in tricky situations that much easier.

The Life module conjures up a feeling of space inside the car more generous than even the latest conversion vehicles can offer. Select materials lend the open and airy cabin a lounge-like character. The use of renewable raw materials is another defining characteristic of the interior, offering passengers a further means of “experiencing” the sustainability of the vehicle. Elements of the instrument panel and door panelling are visibly made from natural fibres, while the naturally tanned leather of the seats creates a lounge-style ambience. Together, these materials provide an appealing contrast to the clear, “floating” forms of the instrument panel and door elements, and lend the interior a strikingly modern feel. With the drive components located in the Drive module, there is no centre tunnel running through the passenger compartment. This allows the two front and two rear seats to be connected with each other by a continuous seat surface, which allows for ease of entry and exit via the front passenger side of the car and means you can park up close to walls, for example. With four seats, wide-opening opposing “coach” doors, boot capacity of around 200 litres and an additional functional compartment in the front, the BMW i3 Concept is neatly equipped for the demands of everyday use.

However, the electric motor developed by BMW and the optimised lightweight design of the LifeDrive architecture cannot take all the credit for imbuing the car with such efficiency and enabling it to travel such long distances on each charge. Indeed, the ability of the car to recoup energy while on the move and special range-extending functions, such as ECO PRO mode, also add miles to the clock. With ECO PRO mode activated, all the vehicle functions operate with maximum efficiency. For example, the accelerator mapping is tweaked to limit the output summoned when the driver flexes his right foot, and the climate control functions also use as little energy as possible. Added to which, sophisticated aerodynamics and slim, low rolling resistance wheels minimise resistance to the car’s forward progress and maximise its range.

Innovative connectivity functions create a seamless connection between the BMW i3 Concept and its customers’ lives outside the car. Remote functions accessible via a smartphone enable owners to find their vehicles, flag up nearby charging stations, allow battery charging and preconditioning at the touch of a button and supply information on the current status of the vehicle. Meanwhile, intelligent assistance systems ease the stress on drivers in monotonous city driving situations and allow them to arrive at their destination more safely and in a more relaxed state of mind.

The BMW i8 Concept and the fascinating approach that underpins it embody the vision of a sustainable contemporary sports car brought to life. Its innovative plug-in hybrid concept combines the modified electric drive system from the BMW i3 Concept – fitted over its front axle – with a high-performance three- cylinder combustion engine producing 164 kW (220 hp)/300 Nm (221 lb-ft) at the rear. The electric motor in the BMW i8 Concept is a full-capability unit which can also power the car on its own, if required. However, working in tandem allows the two drive systems to display their respective talents to the full, delivering the performance of a sports car but the fuel consumption of a small car.

Acceleration of 0 to 100 km/h (62 mph) in under five seconds combined with fuel consumption in the European cycle of under three litres per 100 kilometres (approx. 94 mpg imp) and average customer fuel consumption of between five and seven litres per 100 kilometres (40.4 – 56.5 mpg imp) – even when driven hard – are figures currently beyond the capability of any vehicle powered by a combustion engine of comparable performance. Thanks to its large lithium-ion battery, which can be charged from a domestic power supply, the BMW i8 Concept can travel up to 35 kilometres (approx. 20 miles) on electric power alone. A large proportion of short everyday journeys can therefore be completed with zero emissions. The car’s electric-only mode allows it to enter emissions- capped central areas of cities with access restrictions in place for petrol or diesel-powered vehicles. The i8 Concept’s efficiency rating is further enhanced by its ability to generate energy at both axles. The electric motor at the front axle recoups maximum energy every time the driver brakes, while a high-voltage alternator hooked up to the combustion engine charges the battery, if required. Added to which, the 2+2-seater offers enough space for four people, giving it a high level of everyday practicality.

The emotional design of the BMW i8 Concept ensures its qualities are clear for all to see. Its dynamic proportions give the BMW i8 Concept the appearance of surging forward before it even turns a wheel and lend visual form to its extraordinary performance. The sophisticated concept behind the upward- swivelling doors fixed to the A-pillars underlines the car’s sporting capability and opens up access to the front and rear seats at the same time.

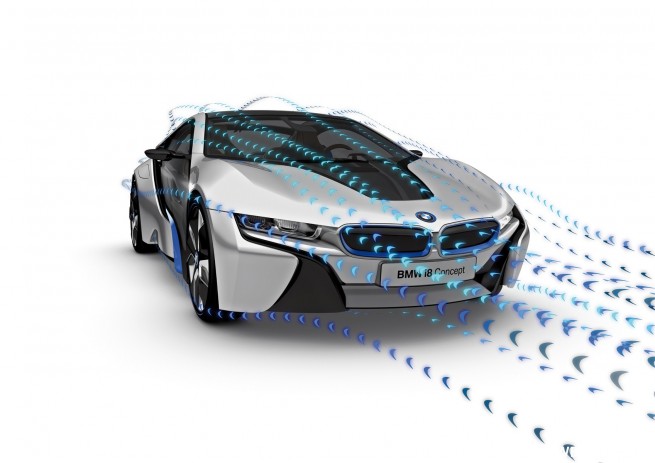

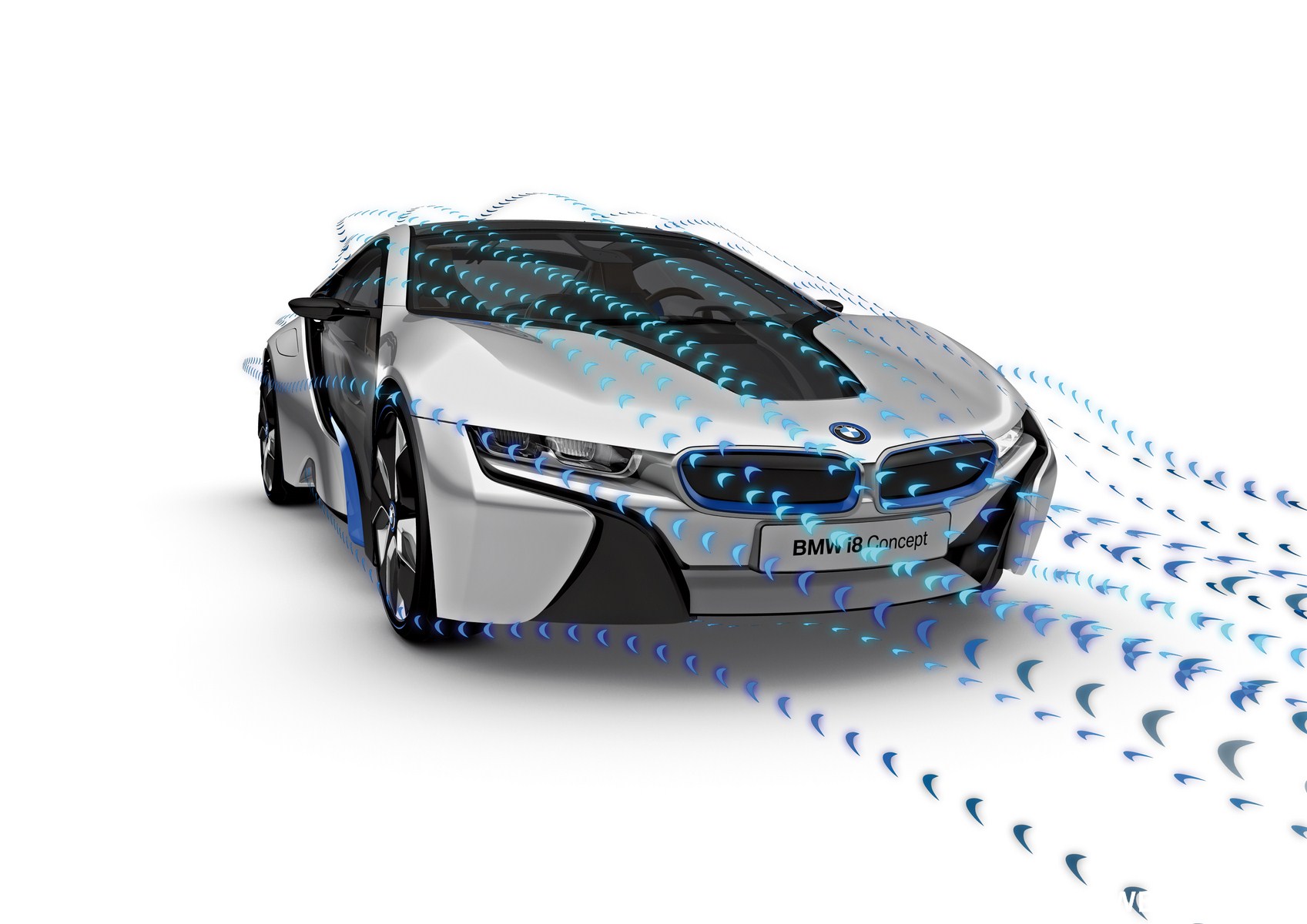

A series of air inlets allow the air to flow through and around the vehicle to optimum effect, ensuring extremely low drag. They also add visual emphasis to these advanced aerodynamics. Airflow plays an extremely important role at the rear of the vehicle as well. Intakes behind the passenger cell and at the rear provide a cooling flow of air through the engine compartment, while outlets in the rear diffuser and the flow of air around the rear wheels ensure the car is extremely efficient in terms of lift and downforce at both axles.

The LifeDrive architecture of the BMW i8 Concept has been carefully adapted to enhance the vehicle’s sports car character, and therefore to deliver unbeatable performance and excellent driving dynamics. The motor in the front axle module and combustion engine at the rear are connected by an “energy tunnel”, which houses the high-voltage battery. This gives the car a low centre of gravity – and the dynamic benefits that come with it. The positioning of the electric motor and engine over their respective axles and the space-saving and well-balanced packaging of all components result in an optimum 50/50 weight distribution.

The weight of every component inside the BMW i8 Concept has been minimised down to the very last detail, allowing the extra weight of the electric drive system and battery to be cancelled out. The BMW i8 Concept therefore presents the ideal environment in which to sample this very special drive concept on the road. The passengers sit – in typical sports car style – in an extremely low and enclosed position inside the CFRP-constructed Life module (mounted above the Drive module).

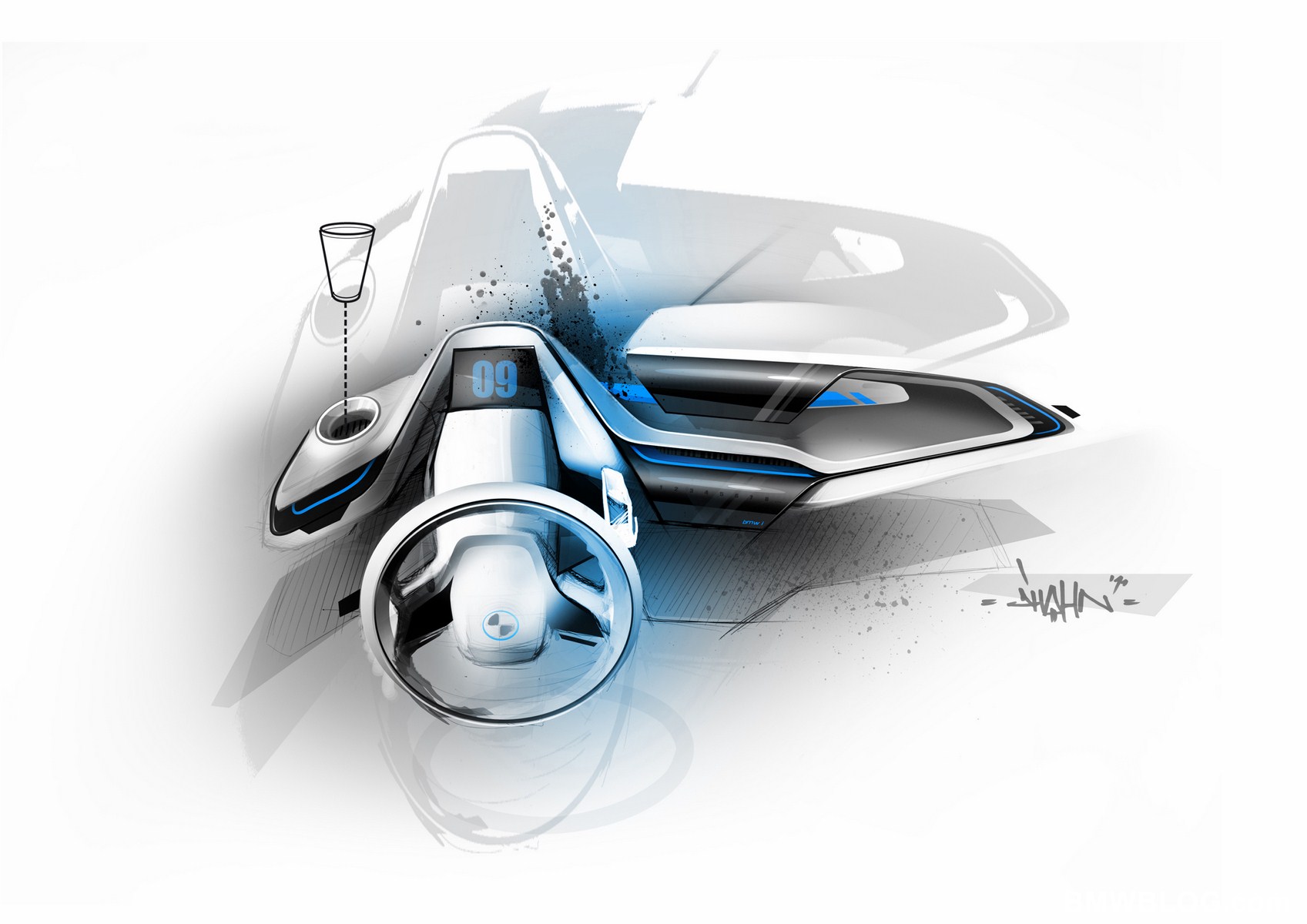

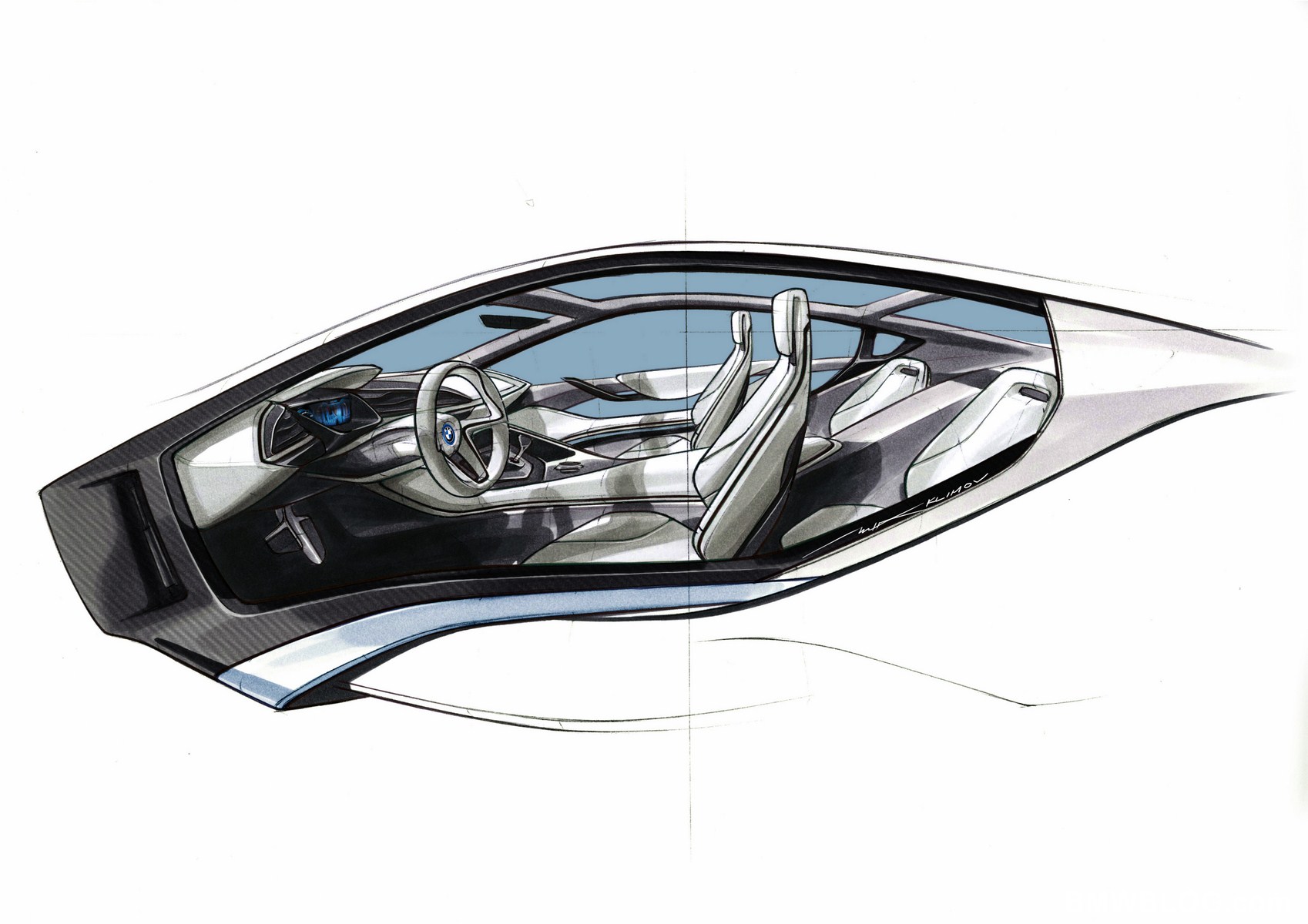

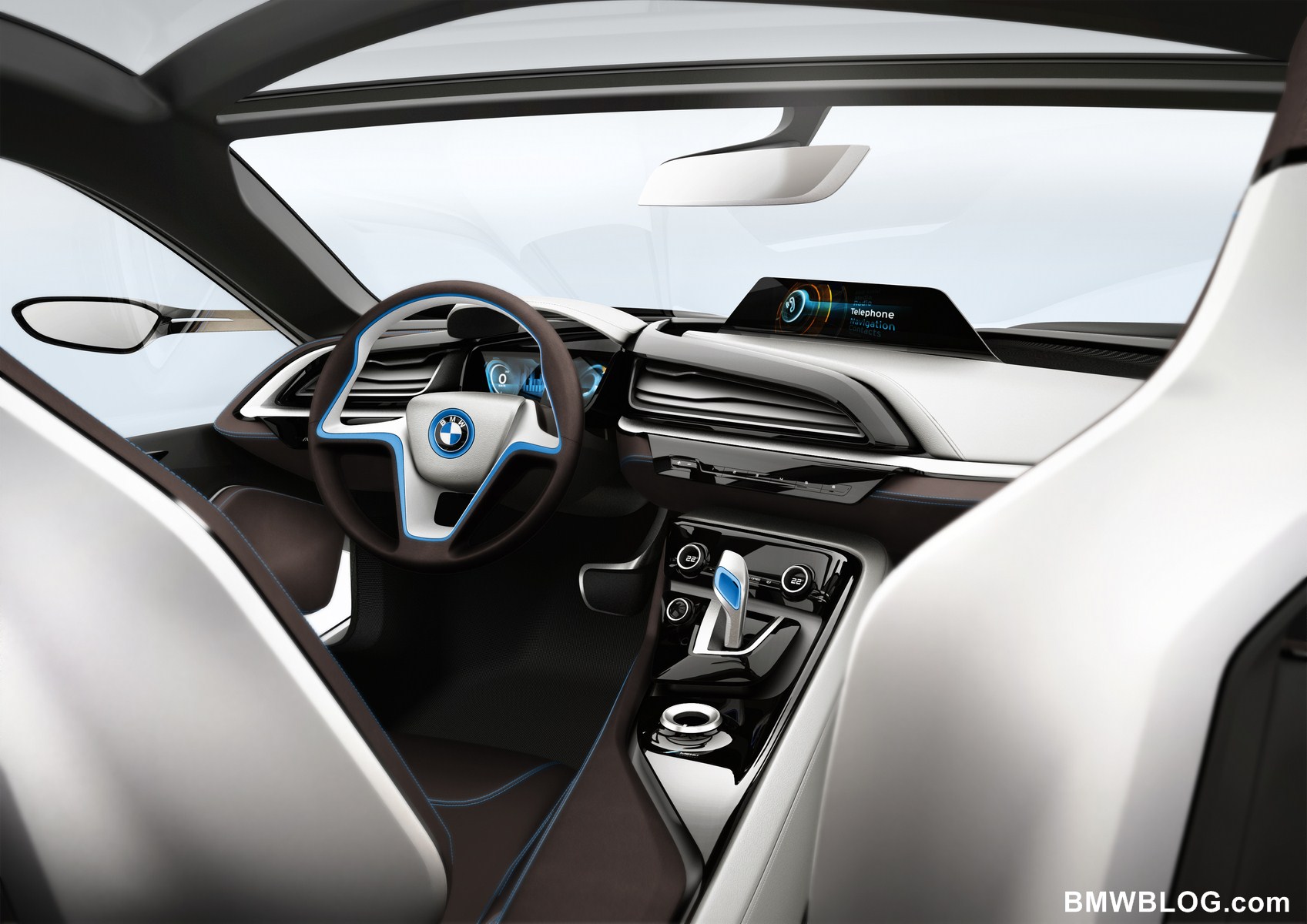

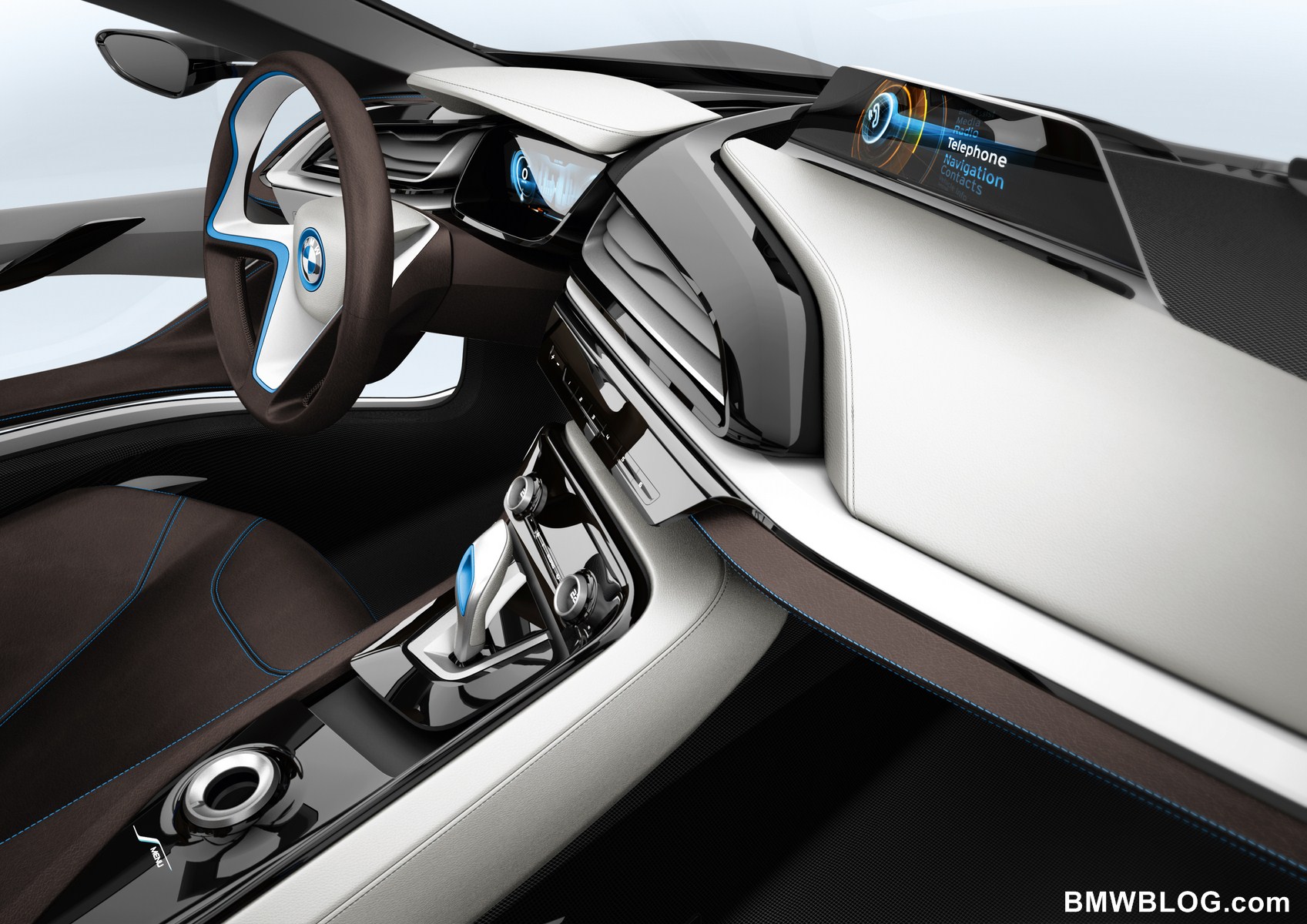

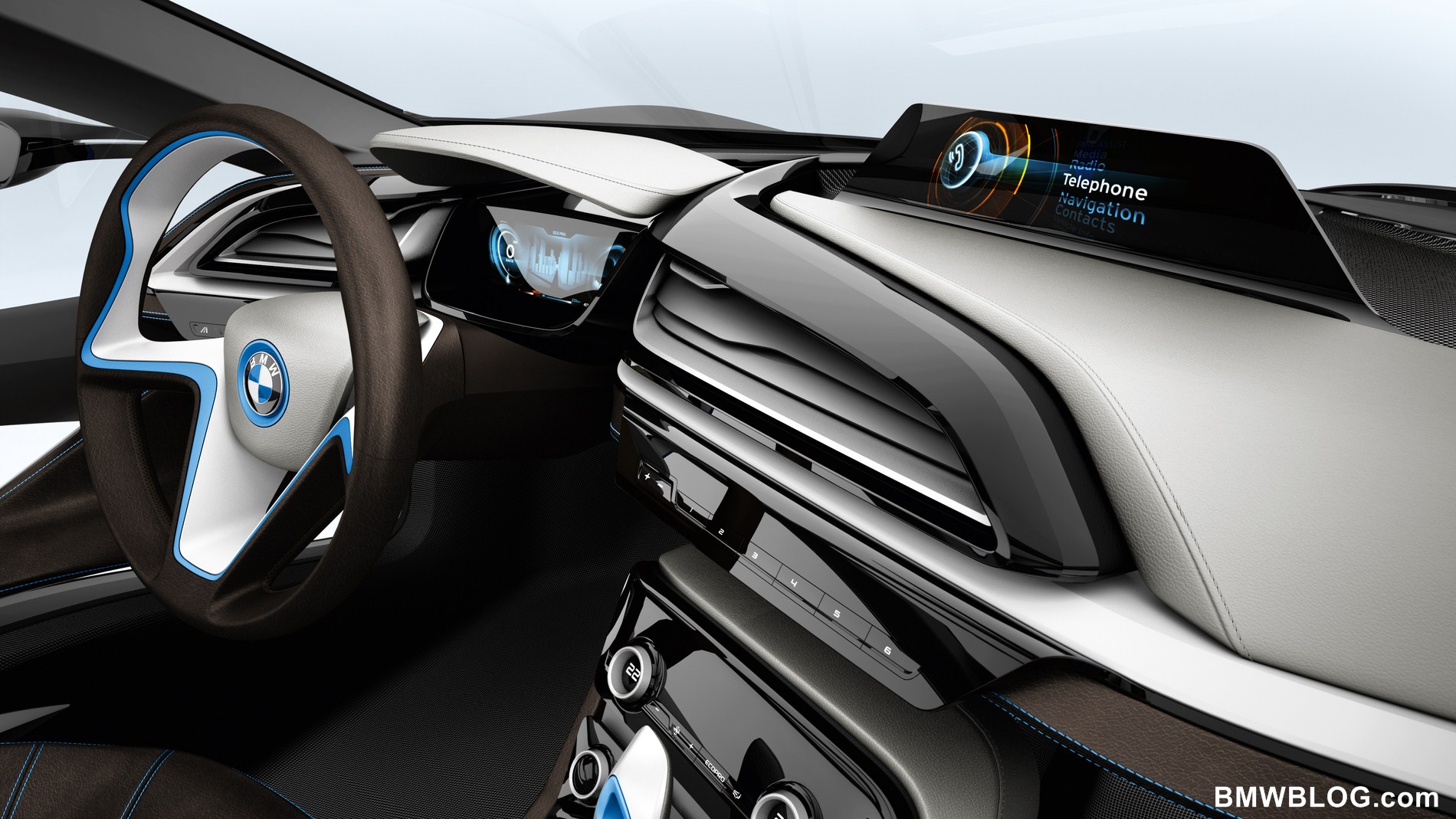

The sporting character of the BMW i8 Concept continues into the interior. Boasting a driver-focused environment unmatched by any BMW Group vehicle before it, the BMW i8 Concept immerses the driver fully in the unique driving experience. The purpose-built driver’s position is geared squarely towards the person at the wheel and gives optimum access to all information and controls. The three-dimensional displays are crystal clear and flash up the relevant information for the driving situation at hand. The interior as a whole is defined by the functionality of a classical BMW sports car and majors on lightness and ease of use. The BMW i8 Concept is the sports car for a new generation – pure, emotional and sustainable.

BMW i thinks beyond the vehicle.

An additional range of mobility services – which can also be used independently of the cars – will be an integral component of BMW i alongside the vehicles themselves. This should allow the creation of a new, profitable area of business over the long term and attract new customers to the company’s brands. A totally new development in this area will be vehicle-independent mobility services. These will allow BMW i to offer bespoke mobility solutions representing a perfect combination of premium vehicles and premium services. The focus is on solutions which will improve usage of existing parking spaces, as well as

intelligent navigation systems with local information, intermodal route planning and premium car-sharing. In addition to service packages developed in-house, the BMW Group is pursuing cooperations with partner companies as well as strategic capital investments with providers of mobility services. BMW i Ventures was established with this purpose in mind. The company aims to expand the product portfolio of BMW i over the long term with stakes in highly innovative service providers, such as MyCityWay and ParkatmyHouse.

Purpose-built design – the LifeDrive concept.

The construction of electric vehicles has, up to now, been based on the “conversion” approach. This involves integrating electric components into vehicles originally designed to be powered by a combustion engine, as in the case of the MINI E and BMW ActiveE test cars. However, this form of automotive electrification involves making complex modifications throughout the vehicle and therefore increasing its weight considerably. That is because the electric drive components place totally different demands on a vehicle when it comes to installation space and cannot be integrated into that vehicle without adding weight and compromising interior and boot space. Conversion cars thus do not represent the best long-term response to the challenge of e-mobility.

The BMW Group engineers took a different approach, focusing squarely on the eventual usage of the BMW i vehicles in developing the LifeDrive concept. This new vehicle architecture meets the full range of technical requirements of an electric drive system (including a large battery), while keeping weight low, maximising range, creating generous levels of space, enabling supreme driving characteristics, and ensuring impressive safety for the battery and passengers alike.

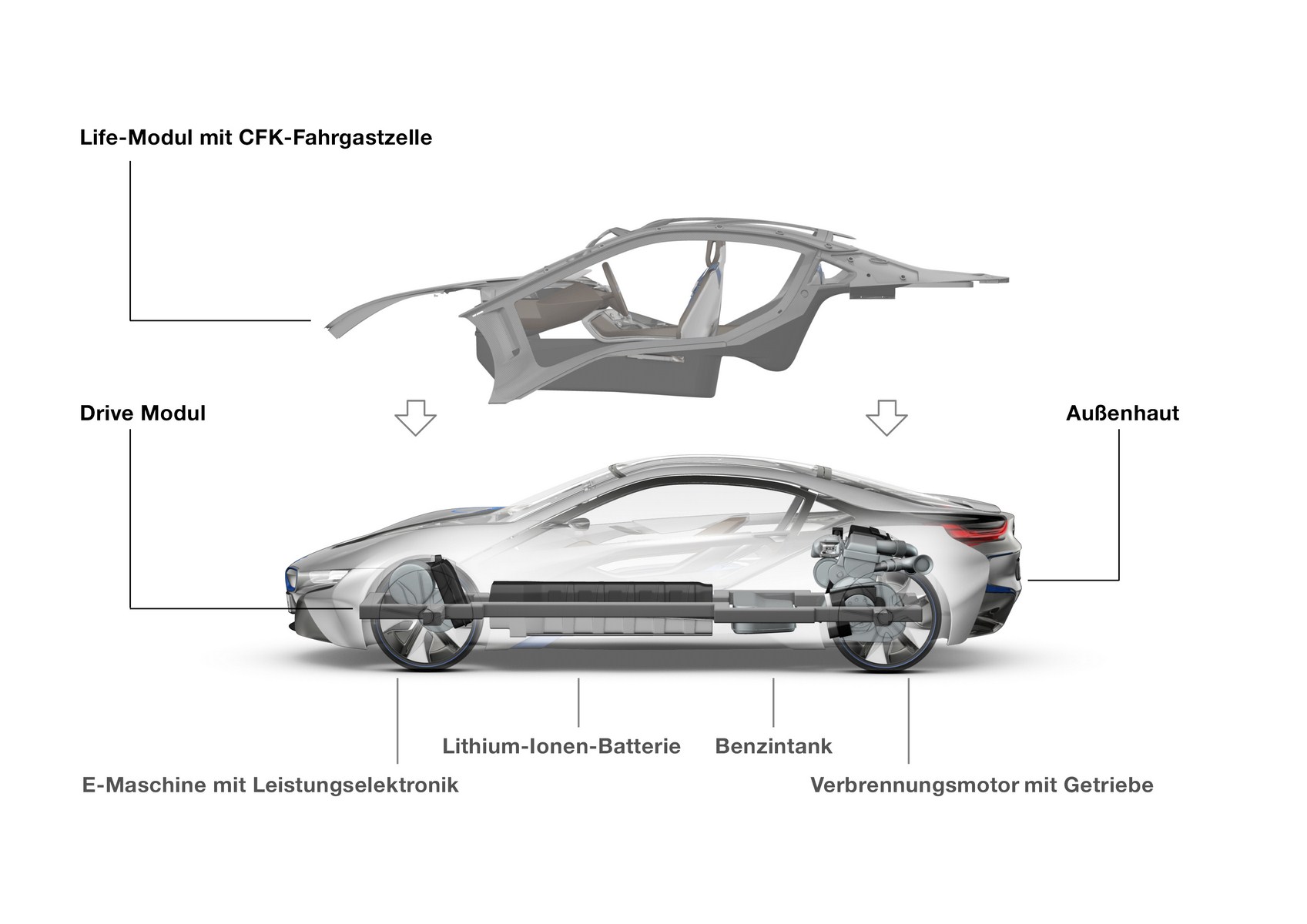

In contrast to vehicles with a self-supporting body, the LifeDrive concept essentially comprises two separate, independent functional units. The Drive module integrates the vehicle’s suspension, battery, drive system, and structural and crash functions into a construction made chiefly from aluminium. Its partner, the Life module, consists primarily of a high-strength and extremely lightweight passenger cell made from carbon fibre-reinforced plastic (CFRP). The use of this high-tech material across large sections of the car ensures that the Life module is remarkably light and, in so doing, helps to achieve both impressive range and improved performance. Added to which, the car’s handling is also much enhanced, and the functional connection between the Drive module and the torsionally rigid Life module lends it a very distinctive dynamic character. The use of CFRP on this scale is unprecedented. Indeed, with the creation of its LifeDrive architecture the BMW Group has taken lightweight design, vehicle architecture and crash safety into a whole new dimension. By avoiding the need for modifications to accommodate the electric drive components, the LifeDrive architecture ensures the car is no heavier than a conversion vehicle of similar size. Intelligent lightweight design and the innovative use of materials allows the LifeDrive architecture to cancel out all the extra weight added by giving the car an electric drive train rather than a comparable combustion engine.

Another special feature of the BMW i3 Concept and BMW i8 Concept are their wheels, which are noticeably larger and narrower than those of their class rivals. Slimmer tyres generate far less drag and rolling resistance, reduce unsprung masses and, in so doing, allow the cars to travel further on a single charge and use less energy.

Lightweight and safe.

Equally impressive as the vehicle architecture’s benefits in terms of weight and handling is its performance in crash tests. Here again, the combination of the aluminium in the Drive module and the Life module’s CFRP passenger cell demonstrates just how well lightweight design and safety can go together. Like the cockpit of a Formula One car, the CFRP passenger cell provides an extremely strong survival area. Pole impacts, side-on collisions and rollover tests highlight the impressive safety-enhancing properties of this extraordinarily robust material. While metal constructions require the addition of large energy absorption zones, special deformation elements in the CFRP structure allow large amounts of energy to be absorbed in an amazingly small area. Despite the heavy and sometimes concentrated forces, the material barely sustains a dent. Together, the high-strength CFRP passenger cell and intelligent distribution of forces through the LifeDrive module lay the foundations for optimum protection for the car’s occupants and battery alike.

The LifeDrive architecture of the BMW i3 Concept.

Both the BMW i3 Concept and the BMW i8 Concept have been designed around the innovative LifeDrive architecture. However, the geometric implementation of the concept differs in the two models, having been adapted to suit their different usages. The BMW i3 Concept features a horizontal-split variant of the LifeDrive concept optimised to accommodate the car’s electric drive system. Here, the Drive module provides the solid foundations for the Life cell, which is simply mounted on top. The driving element of the Drive module’s functional design is the battery, which is made as large as possible to give the car better range. Bearing in mind the size of the BMW i3 Concept’s battery, the most space-efficient place to store it was in the car’s underfloor section. There, it occupies the whole of the module’s central section, giving the car optimum weight distribution and a low centre of gravity and therefore enhancing its dynamics. The battery is penned in by aluminium profiles, which protect it from external impacts. Crash-active structures in front and behind it provide the necessary energy absorption in the event of a front- or rear-end collision. The electric drive system is, as a whole, much more compact than a comparable combustion engine, cleverly accommodating the electric motor, gear assembly and drive electronics – in space-saving fashion – within a small area over the driven rear axle. The BMW i3 Concept therefore features the optimum LifeDrive architecture configuration for a purely electric vehicle.

The chassis of the BMW i3 Concept is also ideal for city driving. Its enviably small turning circle and direct steering responses are a recipe for outstanding agility, notably at low speeds. Rear-wheel drive allows the front axle to remain free from drive forces and therefore to carry out its steering function to optimum effect. These elements team up with the electric motor – whose impressive torque from a standstill provides exceptional traction – to produce extremely dynamic handling characteristics.

The spacious Life module of the BMW i3 Concept allows the vehicle’s interior to boast a totally new design. The integration of all the drive components within the Drive module removes the need for a centre tunnel bisecting the interior, through which power would previously have been transferred to the rear wheels. The BMW i3 Concept therefore offers significantly more interior space than other vehicles with the same wheelbase and – through solutions such as a full-width seat bench – also allows the interior to be adapted extremely effectively to the needs of urban mobility. Added to which, a pair of opposing doors and the omission of B-pillars provide a large entry area for passengers – and a generous view into the cutting-edge interior for admiring eyes. The BMW i3 Concept offers comfortable accommodation for four passengers and, with around 200 litres of boot space, room for their luggage as well. Up front, underneath what would normally be the bonnet, the Life module gives the BMW i3 Concept a separate luggage area with space for the charging cable and other items passengers would rather not carry in the passenger compartment.

The LifeDrive architecture of the BMW i8 Concept.

The BMW i8 Concept sees the LifeDrive architecture concept adapted to suit the vehicle’s sports car character – i.e. primed to deliver leading performance and sharp dynamics. This interpretation of the LifeDrive concept takes its cues from the innovative hybrid concept of the BMW i8 Concept, which links up an electric drive system at the front axle with a combustion engine over the rear wheels to lay on an unparalleled driving experience.

In a departure from the purely horizontal configuration favoured for the BMW i3 Concept, the LifeDrive architecture of its BMW i8 Concept sibling also features vertical layering in the front axle module, passenger cell and rear axle module. The drive systems powering the BMW i8 Concept are integrated into the front and rear axle modules, with the CFRP Life module providing the bridge between the two. As a plug-in hybrid, the BMW i8 Concept is not designed purely for all-electric propulsion, and therefore carries fewer battery cells than the BMW i3 Concept. These are stored in the Life module inside an energy tunnel, a structure similar to a central transmission tunnel. The front and rear axle modules therefore combine with the passenger cell and battery to form a functional unit, which adopts not only load-bearing responsibilities but also extensive crash functions. The location of the high-voltage battery in the energy tunnel gives the vehicle a low centre of gravity, and this enhances its dynamics. Together with the positioning of the motor and engine over the axles, the result is optimum 50/50 weight distribution. Intelligent lightweight design and the innovative use of materials produce extremely low unsprung and rotating masses, which is good news for the car’s driving dynamics, acceleration, range and fuel economy. All in all, the BMW i8 Concept offers the ideal environment in which to experience the special drive concept and distinctive sports car character of the BMW i8 Concept on the road.

The BMW i8 Concept’s axles are designed to deliver optimum handling properties, in keeping with the car’s sporting profile. The multi-link front axle provides the ideal geometric platform for an extremely flat and aerodynamically efficient silhouette. The front axle construction is also designed explicitly to handle the twin demands of the steering and drive system. It eliminates any drive forces which may otherwise affect the steering, ensuring optimum handling in every situation.

In the CFRP Life module passengers sit low down and enclosed – in classical sports car style – between the motor and engine. Between them runs the energy tunnel that intersects the interior. Swivelling doors fixed to the A-pillars provide large openings that allow access to both front and rear seats. Four seats make the BMW i8 Concept a practical everyday vehicle that brings together the full array of positive BMW attributes.

Intelligent lightweight design.

Systematic lightweight design is a particularly important element of electrically- powered vehicles. An electric drive system (incl. battery) tips the scales at up to 200 kg heavier than a comparable combustion engine and full tank of fuel. And high vehicle weight is a major factor – alongside battery capacity –in restricting how far an electric car can travel on a single charge. As well as increasing such a vehicle’s range, lower vehicle weight is also a ticket to noticeably improved performance. After all, a lightweight vehicle accelerates faster, is more agile through corners and brakes to a standstill more quickly. Lightweight design therefore paves the way for greater driving pleasure, agility and safety. In addition, lower accelerated mass means that energy-absorbing crash structures can be scaled back – and that, in turn, saves weight. The aim of the development engineers was therefore to achieve the electrification/hybridisation of the vehicles without adding weight. Alongside the innovative LifeDrive architecture, other aspects central to the BMW Group’s success in cancelling out the extra weight of the electric components were systematic lightweight design and the innovative use of materials.

“The LifeDrive concept avoids the additional weight involved in making the necessary modifications to conversion concepts. At the same time, in both vehicles we’ve been able to cancel out all of the extra kilos added by the electric motor(s) through the innovative use of materials and intelligent lightweight design.” (Bernhard Dressler, Responsible for bodywork and equipment

at project i)

The various components within a vehicle’s structure have to deal with an extremely wide range of demands, which can only be addressed to full effect by a variety of construction methods. For each component, the BMW Group engineers therefore select the material to fit its usage profile and the demands placed on it, so that battery weight is no longer an issue. In order to meet the engineers’ ambitious aims, every component has been rigorously developed, examined and, if necessary, modified to optimise its functional effectiveness and minimise weight. Designing the components specifically for their particular purpose ensures the vehicles work as well and weigh as little as possible. CFRP plays a major role in reducing weight. The extensive use of this material – e.g. in the Life module of the BMW i3 Concept and BMW i8 Concept – is unprecedented in volume vehicle production. CFRP is at least as strong as steel, but roughly 50 per cent lighter. By comparison, aluminium would save “only” 30 per cent in weight over steel. All of which makes CFRP the lightest material available for vehicle body construction which does not compromise safety.

As well as “conventional” CFRP components made from resinated carbon fibre weave, in some areas the BMW i8 Concept also contains specially woven CFRP structures known as “braided profiles”. Here, CFRP preforms are woven like a sock over a mould. This allows much greater design freedom, and fewer joints are required. Flush-fitting connections also make the profiles extremely strong. The braided profiles are therefore used in areas – such as the door sills, doors and A-pillars – in which greater strength is required, not least in the event of a collision. The special manufacturing process involved makes it extremely easy to optimise wall thickness (by adjusting the diameter of the mould). Much more complex forms can also be achieved without bonding or the use of connecting pieces and, most importantly, produce far fewer waste cuttings. Lower material usage also reduces the energy requirement.

Two vehicles, two drive concepts.

BMW i stands for a new concept in sustainable mobility and a new approach to vehicle drive system design. The BMW i3 Concept and the BMW i8 Concept, with their highly innovative and efficient drive systems, demonstrate how future mobility can be both sustainable and dynamic. The BMW i3 Concept and BMW i8 Concept are two entirely different vehicles, and this is reflected in their different drive concepts. In both cases the design and configuration of the drive systems are dictated by the individual character of the vehicle and its intended area of application. While the BMW i3 Concept is an all-electric vehicle and therefore optimally equipped for operation around town, the plug-in hybrid BMW i8 Concept combines its electric motor with an internal combustion engine to deliver a high level of performance. The common link between the two vehicles is their electric motor, which marks a move away from exclusive reliance on an internal combustion engine. These cars are “born electric”, and define a whole new concept in drive technology in their segment.

All-electric – the BMW i3 Concept.

The electric motor of the BMW i3 Concept is designed primarily for operation in an urban environment. Already tested in a pre-production version in the BMW ActiveE, the version of this permanently excited hybrid synchronous motor which will be used in the BMW i3 Concept has undergone further optimisation in terms of weight and driveability. It develops 125 kW/170 hp, with peak torque of 250 Nm (184 lb-ft). Typically of an electric motor, maximum torque is developed from standstill, in contrast to an internal combustion engine where torque increases with engine rpm. This makes the BMW i3 Concept highly agile and provides impressive acceleration. The BMW i3 Concept accomplishes 0-60 km/h (37 mph) in under four seconds and 0-100 km/h (62 mph) in under eight seconds.

At the same time the abundant torque is delivered over a very large rpm range, resulting in very smooth power delivery. The single-speed gearbox provides optimal power transmission to the rear wheels and accelerates the BMW i3 Concept to an electronically governed 150 km/h (93 mph) without the loss of power typically associated with having to shift gears. The speed governor cuts in at this point in the interests of efficiency: going even faster would result in very high energy consumption, which would unnecessarily restrict the driving range. The motor is located directly above the drive axle, for optimal and typical BMW rear-wheel-drive handling characteristics.

But impressive, instantaneous, response is not the only distinctive aspect about the driving experience in the BMW i3 Concept. Another is the dual accelerator/decelerator function of the accelerator pedal. After the driver eases up on the accelerator, the electric motor acts as a generator, converting the kinetic energy into electricity which is then fed back into the battery. Energy recuperation generates a braking effect which makes a significant contribution to vehicle deceleration. Around town, approximately 75 per cent of all braking operations can be performed in this way, i.e. without using the brake pedal at all. Intensive use of this energy recuperation function of the electric motor can increase the driving range by up to 20 per cent. Only when the driver’s braking request exceeds a given level is the conventional brake system of the BMW i3 Concept engaged as well.

A coasting facility makes this unique “single-pedal control” of acceleration and braking using just the accelerator even more user-friendly. The BMW i3 Concept features a distinct “neutral” position of the accelerator pedal, i.e. rather than switching straight to recuperation when the driver eases off the pedal, the electric motor’s zero torque control keeps the drive train disconnected as long as the pedal is in this position. The vehicle now coasts without consuming power, driven by its own kinetic energy. Used as part of a proactive driving style, this coasting mode is a very user-friendly way of increasing the driving range even further.

Compact and powerful – the electric motor.

The electric motor of the BMW i3 Concept not only offers attractive driveability, it also has a very high power-to-size ratio. This is partly explained by the fact that electric motors typically achieve over 90 per cent energy efficiency. This means that a smaller electric motor can produce the same power output as a larger internal combustion engine. Due to its compact size, the electric motor used in the BMW i3 Concept can be optimally integrated into the vehicle architecture. The permanently excited hybrid synchronous electric motor and the power

electronics of the BMW i3 Concept were developed entirely in-house, and boast very high efficiency, optimised power delivery and compact design. As mentioned, the innovative nature of the electric motor is particularly evident in the favourable power-to-size ratio. As a result of continuous development and refinement, the space requirements of the electric motor used in the

BMW i3 Concept have been reduced by 40 per cent compared with the motor used in the MINI E. This compact drive unit is mounted over the rear axle, together with the power electronics, transmission and differential, causing no loss of interior space.

The power needed to drive the vehicle and to operate all other vehicle functions is supplied by specially developed lithium-ion battery cells. The BMW i3 Concept’s battery system has undergone detailed optimisation which significantly reduces the extent to which external factors can influence the vehicle’s power and driving range. An integrated liquid cooling system keeps the battery at its optimal operating temperature at all times, which helps to significantly boost the performance and life expectancy of the cells. The climate/heating system cools the fluid circulating in the battery housing via a heat exchanger.

If necessary, in winter, this fluid can also be heated in order to bring the battery up to its optimal operating temperature of around 20 degrees Celsius. These precautions ensure that power and torque remain constant throughout most of the battery’s charge range and make the system significantly less sensitive to extreme external temperatures. The battery can be fully recharged in six hours at a standard power socket. If a high-speed charger is used, an 80 per cent charge can be achieved in just one hour.

Range Extender increases the driving range.

As the MINI E field tests showed, a driving range of 120 to 150 kilometres (74 to 93 miles) was sufficient to meet 90 per cent of the mobility requirements of the pilot users. However, some customers want a longer driving range, or want their vehicle to be as flexible as possible. The BMW i3 Concept therefore offers an optional Range Extender, the REx, which allows the electric driving range to be increased. REx, a small, very smooth-running and quiet petrol engine, drives a generator which maintains the battery charge level and therefore extends the range of the electric motor. As soon as the battery charge reaches a critical level, REx supplies the necessary energy to get the driver the rest of the way to his destination. In a sense, therefore, the Range Extender is like having a reserve fuel can on board.

The very compact size of the electric motor used in the BMW i3 Concept means there is room left over to accommodate REx and its attached generator over the rear axle, alongside the drive components. The petrol engine complies with the SULEV standard, currently the strictest emissions standard for internal combustion engines. To reduce fuel consumption to a minimum, REx also features such functions as Automatic Start-Stop and other intelligent operating strategies.

Best of both worlds – the BMW i8 Concept.

Whereas the BMW i3 Concept always drives on electric power, the i8 Concept combines the advantages of two different drive systems – an electric motor and an internal combustion engine. As a plug-in hybrid it offers the best of both worlds, combining maximum efficiency with maximum performance.

A 0-100 km/h (62 mph) acceleration time of under five seconds, combined with fuel consumption in the European test cycle of less than 3 litres/100 km (approx. 94 mpg imp) and average real fuel consumption of between five and seven litres (40 – 56 mpg imp) even with a fast driving style are figures unrivalled by any conventional internal combustion-engined vehicle in this power class. Depending on charging habits and the nature of the route, it is even possible to improve on these figures. The secret is the intelligent configuration of the two drive units. In the BMW i8 Concept, the electric motor is not a secondary power source but an equal partner of the internal combustion engine. In this way the BMW i8 Concept achieves a new, ideal balance between the two drive units which results in an optimal combination of efficiency and dynamism.

The electric motor has been adopted from the BMW i3 Concept and modified for use in the BMW i8 Concept’s hybrid power train. It drives the front axle, while a 164 kW/220 hp turbocharged three-cylinder petrol engine developing up to 300 Nm (221 lb-ft) of torque drives the rear axle. Together, the two drive units take the vehicle to a governed top speed of 250 km/h (155 mph). Like the electric motor, the 1.5-litre three-cylinder petrol engine was developed entirely in-house by the BMW Group and represents the latest state of the art in conventional engine design. The pairing of these two drive units in the

BMW i8 Concept reflects the outstanding expertise of the BMW Group in the development of both engines and electric motors.

The energy supplied by the application-designed battery system installed between the front and rear axle modules to the electric motor at the front axle gives the BMW i8 Concept an all-electric driving range of approximately 35 kilometres (20 miles). The battery can be fully recharged in two hours at a standard power socket. The electric motor of the BMW i3 Concept has been specially modified for use in the plug-in hybrid power train of the BMW i8 Concept, i.e. for operation with a smaller battery pack and in conjunction with an internal combustion engine.

A highlight of the BMW i8 Concept is the high-voltage generator attached to the internal combustion engine, via which the internal combustion engine can generate power for recharging the batteries. This option is only used to increase the range of the vehicle while out on the road, and is not intended as a substitute for stationary recharging at an electric power socket.

Maximum performance in all driving situations.

Although the BMW i8 Concept has all-electric capability, the big attraction of this vehicle lies in the combination of the two different propulsion systems. The BMW i8 Concept combines the high-torque responsiveness of an electric motor with the power of an internal combustion engine, a field in which BMW has specialised for many decades. The BMW i8 Concept makes the most of the specific advantages of the two propulsion systems, which complement and support each other perfectly. The two power sources dovetail smoothly to compensate for any loss of power during gear changes. The combined result is that the BMW i8 Concept provides very dynamic acceleration performance across the entire road speed range.

Driving dynamics.

All four wheels of the BMW i8 Concept can be driven at the same time, similarly to an all-wheel-drive vehicle. This solution combines the driving dynamics advantages of front-wheel drive, rear-wheel drive and all-wheel drive. An optimal drive configuration can therefore be provided to suit all driving situations.

When accelerating on dry roads, for example, maximum traction is available at all four wheels, resulting in better driving dynamics and driving enjoyment even when pushing the vehicle hard. In winter, too, the two separately driven axles provide benefits, the four intelligently driven wheels making for enhanced safety on slippery roads and keeping the vehicle moving under almost all winter conditions.

The fact that the electric motor is located at the front axle of the BMW i8 Concept optimises braking energy recuperation, since the front axle is where greater braking forces are developed due to the dynamic wheel load shift when decelerating. Whenever there is a chance to recuperate braking energy, intelligent driving dynamics systems make the most of it, taking into account traction conditions and driving situation, without compromising stability and dynamics. This allows very high levels of braking energy recuperation even in the wet or in snow. Depending on requirements, braking is initially provided by the recuperation function and only when more powerful braking is required is the conventional brake system engaged.

Inspirational design.

BMW i embodies the creation of visionary vehicles and a new understanding of premium mobility underpinned by sustainability. This can be seen and experienced in the inspirational design of BMW i vehicles.

“The design makes the customer a promise of quality that the product experience then keeps. The design of a vehicle shows customers at first glance what they will experience once they get behind the wheel.” (Adrian van Hooydonk, Senior Vice President BMW Group Design)

The task for the designers was to develop a unique design language for BMW i which would reflect the new sub-brand’s claims and values and include scope for expansion, but which would also maintain a strong link to its parent brand. The aim was to create an authentic visual representation of innovative technology and to translate values such as lightness, safety and efficiency into the BMW i3 Concept and BMW i8 Concept models. These basic values are expressed in the design of the vehicles through features including large transparent surfaces and a light-bathed interior, a powerful stance and aerodynamic additions such as contact surfaces, spoiler lips and elements allowing air through-flow. The BMW i3 Concept and BMW i8 Concept also blend in their own interpretation of familiar BMW design features, cementing a clear link to the BMW parent brand.

An overview of hallmark BMW i design features: The BMW i badge.

BMW i is the embodiment of “next premium”, which extends the idea of premium to encompass future requirements. To this end, a three-dimensional blue ring has been added to the outside of the BMW badge for BMW i. Here, the colour blue fulfils two functions. On the one hand it has a traditional association with the BMW badge, but it is also familiar from concepts such as Efficient Dynamics, clean drive systems and zero emissions. The BMW i badge therefore creates a stylistic link between the parent brand and its claim to expansion while giving the sub-brand’s story the perfect visual headline.

The BMW i logo.

The BMW i logo was developed by BMW Design on the basis of an idea born within the walls of BMW Group DesignworksUSA. The design of the logo accurately conveys the sub-brand’s character. “i” is the smallest letter in the alphabet, but the logo’s designers have given it a little extra presence by framing it as a transparent cutout. This fits in rather neatly with the ideas of openness and transparency underpinning BMW i; customers can see and explore the theme of sustainability in all aspects of the sub-brand, its logo included.

BMW i design features at the front end.

The kidney-shaped radiator grille is a signature design feature of the BMW brand. And as such, it is also a fixture in the front of BMW i vehicles. The sub- brand’s models come with a stylistically modified and strikingly individual update on the kidney grille theme, and add a blue background to the design. The innovative drive concept of the BMW i vehicles removes the need for large cooling air intakes at the front, and the grille area is therefore shielded off. The distinctively shaped LED headlights at the outer edges of the front end redefine BMW light design. Along with the strikingly revised kidney grille, the LED-backlit U-shaped lines form an important part of the eye-catching new BMW i face. The minimalist interpretation of the front end highlights the efficiency and lightness of the vehicles and lends them an appearance all of their own.

The stream flow.

The aerodynamically optimised “stream flow” represents one of the most striking design themes of the BMW i vehicles. Like the Hofmeister kink favoured by its parent brand, this new C-pillar treatment can be viewed as a signature styling cue. Two horizontal lines converge from above and below – like streaks of air in the wind tunnel – into a dynamic C-pillar sweep, lending visual form to the efficient aerodynamics of the BMW i vehicles.

BMW i design features at the rear.

BMW i also introduces a fresh take on the classically BMW L-shaped tail lights. Their new design maintains a clear association with the parent brand, yet at the same time gives the rear its own individual presence. The distinctive tail lights make a clear statement of BMW i family membership – during the day or night.

The design language of the BMW i concept cars: Exterior design.

The most defining element of the BMW i models is their purpose-built basic construction, the LifeDrive architecture. Within this concept, the CFRP Life module houses the passenger compartment, while the Drive module brings together all the operational driving functions. This distinctive two-way split is also reflected in the design of the cars. The modules are partly covered by side panels, but remain clearly distinguishable. Expressive surfaces and precise lines form a harmonious transition between the two. This overlap and interlocking of surfaces and lines – “layering” in BMW i speak – marks out the exterior and interior design of both vehicles. The striking interplay of lines and surfaces highlights the linking together of the individual structures and their arrangement within the framework of the LifeDrive architecture. Added to which, the different functions of the layers are colour-coded. The silver external panelling makes up the outward-facing level, while the black function layer of the exterior contains the windows, basic structure and supporting elements. In between, surfaces in bright Stream Blue – the colour used for the BMW i logo – lend high-quality touches. The various levels are set apart from each other clearly, the lower layers also performing certain functions, such as air channelling. The perceptible difference in height between the layers lends the exterior an extremely dynamic, three-dimensional appearance.

The Life modules of both concept cars come across as bright and open thanks to their large, transparent surfaces. This high degree of transparency imbues them with an airy feel and – together with the generous portions of exposed CFRP on display – reflect the lightness and efficiency of both vehicles. A transparent roof opens both vehicles to the sky and generates a very open driving feeling. This reveals the intricate CFRP structure of the roof, adding further emphasis to the lightweight design concept of the two vehicles. The generously-sized glass surfaces give an optimum view out of the cars and allow the passengers inside to experience the outside world while on the move. At the same time, admirers on the outside can also see clearly into the cars, effectively turning their interior into part of the exterior design.

Aerodynamics and design.

Aerodynamics are an important element of efficient mobility and therefore of BMW i. Indeed, they play a key role in giving the BMW i cars their lower fuel consumption and impressive range. The importance of aerodynamics is also reflected in the two models’ exterior design. The “stream flow” – the striking transition of the greenhouse into the C-pillar – is a nod to the vehicles’ efficient aerodynamics and imbues the side view of the cars with an extra dose of dynamism. The aerodynamic form of the stream flow on the BMW i8 Concept significantly improves its aerodynamic efficiency; integrated into the BMW i3 Concept it improves all-round visibility. Meanwhile, the underbody of the two vehicles is totally enclosed and has a smooth surface to counteract the under-car turbulence that would otherwise push up fuel consumption. Moving further back, the structures above the tail lights and the large air outlets underline the reduction in drag achieved over the vehicle as a whole. Another stand-out feature of the BMW i vehicles are the conspicuously large and relatively narrow wheels. In addition to significantly lower drag, these wheels also give the cars a very solid and dynamic appearance. Other aerodynamic elements include the AirCurtains, which ensure optimum air flow around the wheel arches, and the aeroflaps in the door sill area behind the front wheels. Both solutions reduce the cars’ drag substantially, and in so doing increase their efficiency – and therefore their range when running on electric power alone.

Bringing the outside in – layering and free forms in the interior.

As with the exterior, the design principle of layering – the interplay of powerfully expressive surfaces across several levels, defined by precise lines – is also at work in the interior. The interior consists of three different levels, which allow a range of functions to operate and shape the way in which they do so. The three layers have different colours to indicate which functions they accommodate. The layering concept from the car’s outer skin therefore continues inside and highlights the shared design elements of the interior and exterior. The outer level – the white layer – forms the supporting structure for all interior geometries. The elements it contains give the impression of almost being folded, exude a feeling of lightness and yet are very strong. The inner layer is the function-oriented level and opens up features such as seat surfaces and storage areas. The instrument panel includes an additional black level between the inner and outer layer, which incorporates the technical components. This technical layer runs through the whole front section of the interior and also creates a visual link between the instrument panel, steering column and steering wheel (including instrument cluster), central information display (CID) and controls. Positioned here are features including the openings for the air vents, while the displays and radio/climate control panel also develop out of this layer.

Exterior and interior united.

All in all, the exterior and interior of the two vehicles paint an extremely harmonious picture. The designers worked very closely together during the design process, and consequently the exterior and interior have much in common. Open the door and the boundaries of the interior and exterior begin to blur in the interplay of surfaces, for example, creating harmonious connections between the vehicle areas. The surfaces of the exterior and interior melt into one another in the clearly designed entry area. And when you close the door again it is still possible to see through these surfaces onto – or, more precisely, into – the interior.

Another element that brings together the inside and outside of the cars is the partly visible carbon frame. Opening the doors reveals the frame and creates a link between the interior and exterior. The CFRP possesses a highly functional appearance in both vehicles, with the composition and structure of the relevant parts clearly exposed. In contrast to the exposed carbon components with three- dimensional web structure familiar elsewhere, here you can see the load-bearing, two-dimensional weave of the CFRP preforms.

The colours and materials concept creates another link between the vehicles – and between their exteriors and interiors. The dominant colours of the exterior are the Silver Flow shade of light silver and High-gloss Black. The slightly blue- tinged, bright silver colour tone shows off the vehicles’ technical, modern exterior design extremely effectively and presents a clear contrast against the black- painted surfaces. It gives a feeling of motion, adds contours to the expressive surfaces and lends the vehicles an impressive visual depth. Contrasting touches in bright, forceful Stream Blue bring the efficiency of the vehicles (inside and out) stylistically to life. Externally this colour can also be found in the logo, the kidney grille, door sills and rear apron. Together the various shades produce an extremely high-class exterior impression, maximising the impact of high-gloss surfaces and the contrast of black, silver and blue. The glass surfaces further highlight this contrast.

Applied more discreetly in the interior, Stream Blue glows subtly from the logo in the steering wheel, the seats, and between the leather surfaces and structural layers of the steering wheel, as well as from the indicators and displays. The blue double-stitching on the seats packs a considerable visual impact, divides the seats stylistically into their different sections and creates an effective transition from the backrests to the doors. The colours of the interior paint a far warmer picture and therefore create a pleasant contrast to the technical cool of the exterior. The plastic layer structures in Porcelain White and the warm dark brown leather colour tone Mocha Brown conjure up a modern yet cosy ambience. The soft, exquisite leather has been naturally tanned without an additive in sight. However, it is also used extremely sparingly in the interior of the two vehicles, only covering those areas which will see direct contact with passengers – such as the seats and inner sections of the instrument panel.

Sustainability in the interior.

A stand-out feature of the BMW i3 Concept interior is the visible use, for the first time, of renewable and naturally treated raw materials. This allows the vehicle to express the brand’s claim to sustainability throughout its value chain in stylistic terms. The BMW i3 Concept sets new benchmarks in the use of sustainable materials. In addition to the extensive use of natural fibres in the floor pan and naturally tanned leather, 25 per cent of the weight of the interior plastic is accounted for by recycled or renewable raw materials. All in all, this is another great opportunity taken when it comes to reducing the environmentally damaging CO2 emissions of the cars.

BMW i3 Concept – compact, agile, sustainable.

The design of the BMW i3 Concept reveals the car’s qualities the first time you set eyes on it. The BMW i3 Concept represents the dynamic interpretation of an impressively practical vehicle.

The proportions – dynamic, compact.

Agile and compact proportions showcase the agility of the BMW i3 Concept and the dynamic prowess of its electric drive system. The stylistic lines within the car’s proportions provide additional emphasis here. From the side view, a number of elements combine to create a dynamic wedge shape, giving the car the feeling of pushing forward before it even turns a wheel. The generously-sized

greenhouse tapers towards the rear and, together with the rearwards-rising door sills, emphasises the car’s dynamic inclinations. Above the greenhouse, the “stream flow” – a dynamic stroke descending from the roof into the C-pillar – adds further urgency to the forward-surging stance. From the outside, a flowing silhouette and long wheelbase hint at the extraordinarily generous levels of space on offer in the interior, while short front and rear overhangs make parking in tight spaces that much easier. Practicality gets another boost from the “coach doors”, whose opposing construction creates a fresh new way of accessing the wide- open spaces of the interior.

“The design reveals the driving pleasure on offer with electromobility. And you can add to that a large and practical interior.” (Benoit Jacob, Head of BMW i Design Team)

Extensive glass surfaces and black elements like the window surrounds and door sills give the vehicle a feeling of lightness and, together with the exposed carbon structures, draw attention to its low weight. At the same time, the lack of B-pillars ensures a seamless transition between the two doors. The result is a large, homogeneous glass surface, which gives the car’s flanks a very transparent look. Large, narrow 19-inch wheels add further impact to the dynamic side profile of the BMW i3 Concept. Their slim construction allows them to reduce the car’s drag and rolling resistance, and to avoid encroaching into the interior. And that means more space for the passengers.

The striking front end.

The front end of the BMW i3 Concept has a very clear and uncluttered design. The dominant element here is the strikingly moulded kidney grille, which has the hallmark BMW i blue background and – thanks to the car’s all-electric drive system – is totally blanked off. The grille also has a conspicuous swage line picking up from the bonnet edge. Below the kidney grille, the silver-coloured outer layer lends the sculptural front apron its form. The precise, vertical edges of the front apron element serve as the vehicle’s side borders and reinforce its powerful stance on the road. Black surfaces identify the functional areas of the front end, such as the load compartment under the bonnet and the air inlets.

The eye-catching LED headlights usher in a fresh take on BMW light design. Along with the strikingly formed kidney grille, the U-shaped LED-backlit lines form an important part of the arresting new BMW i face. The minimalist interpretation of the individual headlights underlines the efficiency and lightness of the BMW i3 Concept and lends it an individualist, outward-looking and reputable air.

The functional rear end.

The rear end of the BMW i3 Concept represents a microcosm of the car’s impressive functionality overall. The large, retractable rear window offers optimum access to the luggage compartment, and the roof pillars stand upright to create as much space as possible in the interior. Its large glass area allows the rear window to offer unbeatable rear visibility. The rear window is also home to the tail lights, which are U-shaped (like the headlights) and appear to be floating in the glass. Behind it lies an extremely versatile boot area, whose capacity can be further increased by folding down the rear seats.

The wide, silver-coloured rear diffuser marks the body’s lowest edge and allows the driver to experience the car’s efficient aerodynamics. Bordered by a blue layer, the diffuser tapers heavily towards the road and appears to continue underneath the car. The form of the diffuser underlines the car’s powerful stance. A sportier version can be found on the BMW i8 Concept, forging a link between the two models.

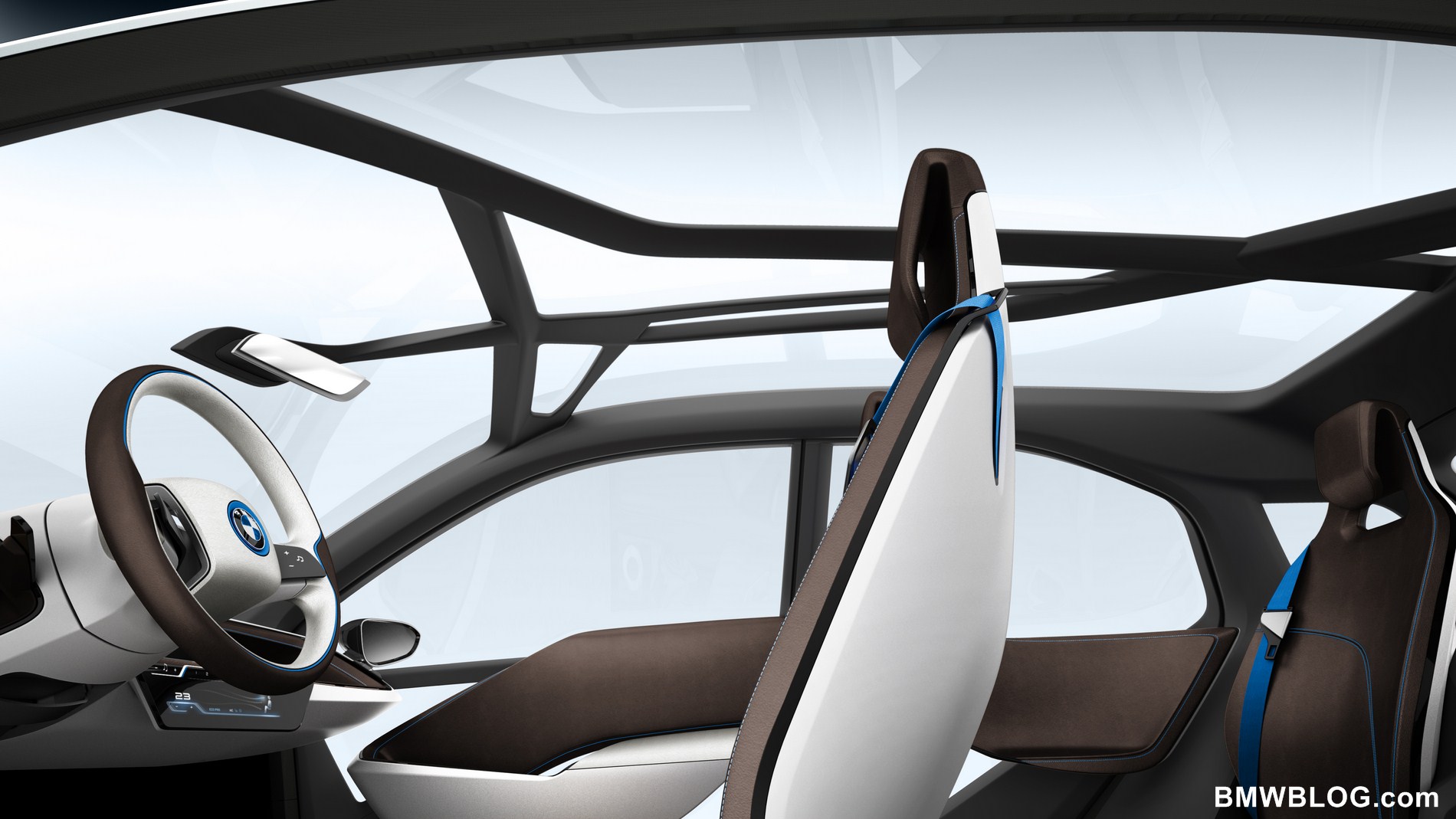

Self-supporting and light – the interior.

The version of the LifeDrive architecture that underlies the BMW i3 Concept opens up totally new avenues in interior design. Since the battery is located entirely in the underfloor section of the Drive module, the whole of the Life module is given over to the interior – a further benefit of purpose-built design. There is no centre tunnel bisecting the cabin, and the interior creates a very free, open and airy impression. At the same time, the design of the interior is extremely modern and clean: taut lines, powerful contours and small radii dominate the geometric forms on display. Here again, the Porcelain White support structure, black technical level and comfort section with Mocha Brown leather are split into separate layers.

The passengers sit in a raised position in the generously-sized Life module of the BMW i3 Concept. This semi-command position provides a good view over the hustle and bustle of city traffic and, at the same time, eases access to the

seats. The full-width seat benches in the front and rear create a new and connecting feeling of space for the passengers in the light interior. With the benches stretching like bridges across the interior, passengers no longer sit strictly apart. This layout also allows them to swap from one side of the car to the other and, if necessary, to all climb out of the car comfortably on the same side. This represents a major boost to comfort in tight parking spaces and when access to one side of the parked car is impeded. The front seat bench features delicate-looking seat backrests marking out the driver and front passenger seats. The slim backrests are a faithful expression of the car’s systematic lightweight design and, at the same time, create more legroom for the rear passengers. The backrests are only connected with the seat bench towards the centre. At their outer edges they appear to be floating freely, which further underlines the airy character of the interior. Another special design element are the blue straps behind the seats, which run diagonally across the backrest and offer another functional stowage facility.

A distinctive element of the light interior is the freestanding steering column, around which all the other elements are grouped. Its pared-down surroundings leave the steering column to extend out prominently into the interior, while cut- outs in the column add to the airiness of the interior. All the driving-oriented controls – such as the instrument cluster, start/stop button and gearshift lever – can be found on the steering column. The gearshift lever takes the form of a rotary controller which can be moved forward or backward to select the desired driving mode – the car moves in the direction indicated by the controller. Positioning the controls on the steering column removes the need for a centre console in the BMW i3 Concept, and integrating the iDrive Controller into the seat bench eliminates this dividing element between the driver and front passenger. Another functional detail is the cupholder, which is integrated to the left of the driver in the air vent. This neat solution allows drinks to be kept warm in the winter and cooled by the climate control system in the summer.

Contrasts as a calculated design element.

Taken as a whole, the interior – with its warmer colours – provides a pleasant contrast to the cool and technical air of the exterior. And there are many other contrasts to be found when you get down to the details. Behind the steering column the extremely intricate yet extensive instrument panel spans the interior.

It begins at the air vents next to the steering wheel, continues in a line around the steering column, includes the radio and climate controls, and continues on its path to the front passenger. Shortly before the front passenger door it then shears upwards, heads back towards the centre of the interior and reaches the end of its journey in the central information display (CID) monitor positioned above the control panel for the radio and climate system. Connectivity – the linking up of the driver and passengers with the outside world and information superhighway – plays an important role in the BMW i3 Concept, and is a theme given prominent treatment by the interior designers. For example, the instrument panel generates an almost calligraphic surface design around the displays, one large, wide surface sweeping prominently into a narrower and more delicate counterpart, before culminating in another wide section. The CID and control unit therefore present an attractive contrast to the clear, precise borders of the instrument panel.

The area around the instrument panel, the doors and the floor area of the BMW i3 Concept also features contrasting materials. The entire lower area of the BMW i3 Concept interior consists of renewable raw materials. The natural origins of the high-strength dark anthracite material made from compressed and coated plant fibres are clearly evident and showcase the light and beautifully crafted elements of the interior to optimum effect. The subtle background sets off individual elements such as the instrument panel and door pockets extremely effectively and, at the same time, underlines their function.

The dark Mocha Brown leather also provides a pleasant contrast with the Porcelain White support structures of the seat bench and instrument panel, and brings a homely lounge character into the vehicle. A large, light-grey wool felt floor mat with blue trim completes the warm and cosy feel. A further contrast to the transparent, pared-down design of the interior is provided by the support structure in the roof, whose organic, branched-out appearance recalls the myriad tentacles of a road network.

Interface design delivering intelligent mobility.

In the BMW i3 Concept, three large displays act as interfaces between the vehicle, the outside world and the car’s occupants. These screens provide access to vehicle and environment-related information, such as the current driving conditions and battery charge, route guidance and nearest charging

stations. The freestanding instrument cluster, meanwhile, emerges out of the steering column directly in front of the driver. With a 6.5-inch (16.5 cm) screen diagonal it displays all the relevant driving information in the driver’s field of vision. Its freestanding design generates a very free and open feel around and above the driver’s head. Meanwhile, the central 8.8-inch (22.4 cm) information display curves out of the black technical layer of the instrument panel’s upper section towards the passengers. It blends seamlessly into the black surrounds, creating a very high-quality, continuous black surface which makes the display appear even larger. Below, the likewise unbroken black audio/climate control panel shares the form of the central information display (CID). Like the CID, the homogeneous touch-control surface curves towards the passengers and uses another screen to show additional information relating to the content on the central information display.

On another level, the highly technical-looking display graphics of the instrument cluster and CID lend visual form to the BMW i3 Concept’s electric drive philosophy. All the information is displayed in the high quality and visually appealing fashion you would expect from BMW. Although the relationship of the i3 Concept to the parent brand is clearly evident again here, a very distinctive graphics profile has been created for BMW i with the emphasis on an individual and minimalist approach. All the displays are three-dimensional. The efficiency display, which takes the form of an open-topped ellipse, surrounds the digital speed screen in the centre of the instrument cluster. Its gauge tells the driver whether energy is currently being taken from the battery or supplied to it through recuperation. The driver can also find information here on the car’s remaining range and driving mode currently selected. If the driver switches to range- enhancing ECO PRO mode, the whole display concept also changes. The ellipse in the instrument cluster becomes flatter, the projected range increases and a display showing the optimum accelerator position for efficient driving completes the new format. The climate control panel also provides visual confirmation of the function-related changes in ECO PRO mode. The driver is therefore kept very effectively informed and given the best possible support in every driving mode.

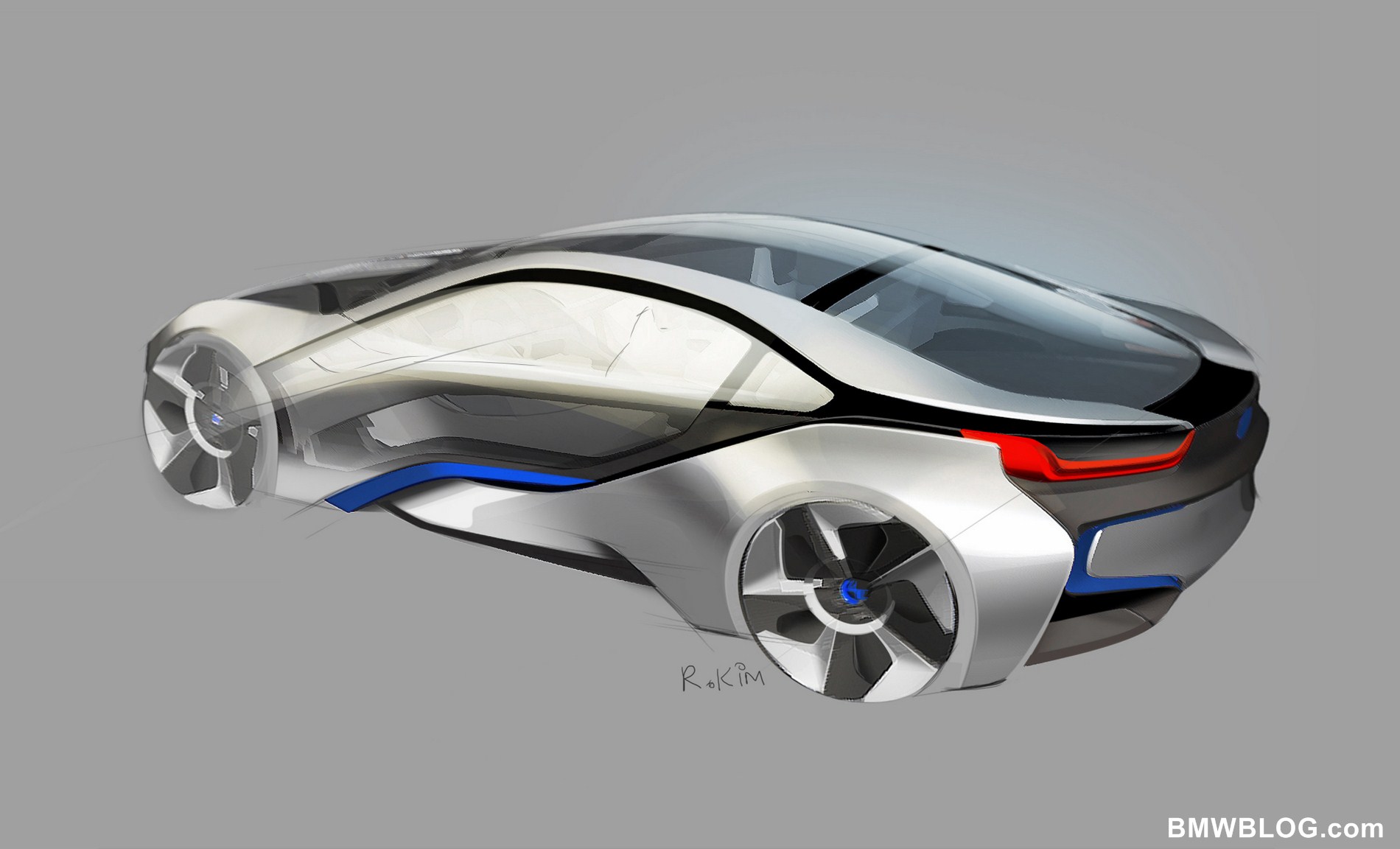

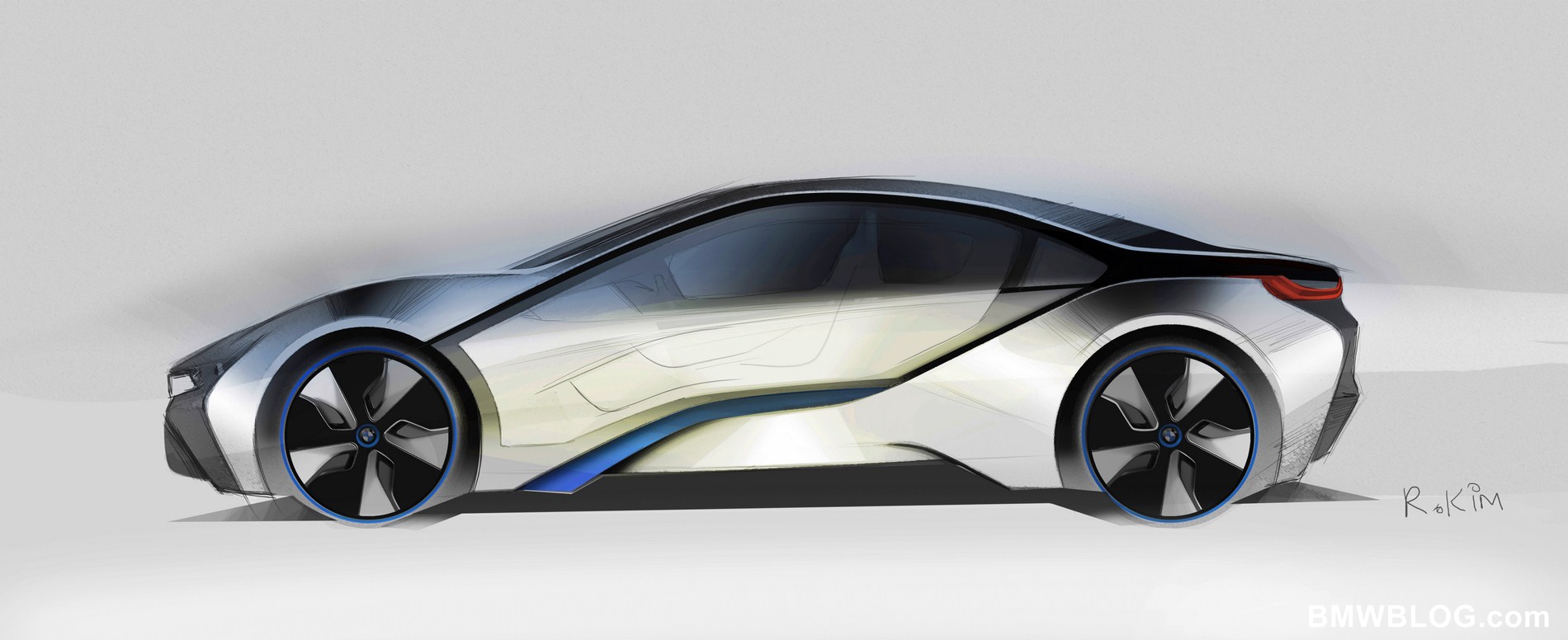

Efficient and dynamic – the BMW i8 Concept

The design of the BMW i8 Concept is as special as the car’s overall concept, embodying the perfect synthesis of technology and aesthetic allure. Its sweeping lines and flat silhouette lend the vehicle a strikingly dynamic appearance even when standing still. Taut surfaces and precise edges combine to form an extremely sculptural and organic surface structure. The BMW i8 Concept appears to have been cut from a single mould, with the front end, flanks, rear end and roof flowing smoothly into one another. Dynamic surfaces and forms generate attractive light and shadow effects, which add emotional emphasis to the car’s light and sporty character. A large, transparent greenhouse lends the exterior an extraordinary feeling of lightness and highlights the exceptional efficiency of this vehicle concept. Short front and rear overhangs round off the sporting overall impression. Despite its dynamic appearance, the 2+2-seater can accommodate four people, giving it a high degree of everyday practicality.

As with the BMW i3 Concept, layering again serves as the central design element of the interior and exterior. The individual vehicle components are also clearly visible from the outside, the black and transparent Life module clearly setting itself apart from the silver-coloured body components around it. The overlapping surfaces and carefully positioned joints enable a reduction in the number of parts required and therefore also a drop in the car’s weight. Indeed, the airflow-optimising surface structure can meet aerodynamic requirements without the addition of extra body elements. This layering approach lends the BMW i8 Concept an extremely technical and cutting-edge appeal.

Dynamic side view.

The precise lines along its flanks and hallmark BMW i “stream flow” give the BMW i8 Concept a strong sense of powering forward even when it is standing still. Plus, the compact packaging of the electric motor over the front axle has allowed the designers to give the car an extremely low and aerodynamically efficient front end. The BMW i8 Concept’s doors swing upwards like wings to provide an undeniably emotional and sporting allure. The high-strength carbon passenger cell allows large door openings which give access to the front and rear seats at the same time. Like the rest of the exterior, the construction of the doors is shaped by the overlapping of several layers of material. Below the doors, the silver-coloured layer moulds the car’s flanks into a powerful wedge shape, opening out from the door sills towards the rear. A blue flourish accentuates the dynamic presence of the sills. Together, the bonnet and door sill sculpting emphasise the BMW i8 Concept’s forward-surging stance, and their smooth lines imbue the car with an extra lightness.

Striking front end.

The BMW i8 Concept also displays its dynamic sports car persona when viewed from the front. A number of different levels interact with one another in the design of the front end, while sculptural air intakes and channelling ducts evoke a feeling of depth. The expressive surface treatment exudes dynamic verve and advertises the car’s sporting potential. The broad kidney grille and flat headlights emphasise the car’s low-slung and dynamically wide-set stance. The full-LED headlights of the BMW i8 Concept also adopt the signature BMW i U-shape with two adjacent arches. Set back slightly into the body and framed by a U-shaped surround, the headlights give the car a sporty and urbane appeal.

A black, semi-transparent “V” rises out of the bonnet just behind the kidney grille, opening out towards the windscreen and guiding the eye to the electric motor below. The “V” also offers the first glimpse of the CFRP module and extends back towards the rear like a black band to provide a visual connection between the different sections of the car.

Sporty rear end.

Similarly to the front end, the rear of the car is also very low, horizontal and sculptural in design. The silver-coloured side sections form a striking vertical frame around the rear of the car, with a precise line extending out to the sides enjoying particular prominence. This line also serves as a spoiler lip and emphasises the aerodynamic efficacy of the rear end. In its centre the silver- coloured and blue-framed rear diffuser is a wider and lower interpretation of the version on the BMW i3 Concept, adding a distinct sporting flavour to its relationship with its stablemate.

In this area of the car the exceptional sporting credentials of the BMW i8 Concept are expressed in width-accentuating lines, three-dimensional air outlets and “floating” tail lights with air through-flow. The tail lights, which also have a distinct horizontal design, are integrated into the upper layer of the rear and share the signature U-shape of the BMW i light concept.

BMW i8 Concept: putting the dynamic into aerodynamics.

The efficient aerodynamics of the BMW i8 Concept can be seen in a host of different details. Numerous parts of the car’s body serve as air guidance elements. Narrow openings around the front apron guide the inflowing air into two AirCurtains. These enclosed ducts channel the air along the inside of the front apron to the wheel arches, where it is expelled at high speed through an extremely narrow outlet, brushing past the tyre sidewalls as it goes. The out- rushing jet of air hangs like a curtain over the sides of the front wheels and minimises turbulence in this area. Added to which, the car’s underbody is totally enclosed and has a smooth surface to counteract the under-car turbulence that would otherwise push up fuel consumption. Meanwhile, the hallmark “stream flow” on the sides of the car highlights its optimised air flow and air channelling capability. Moving further back, the structures above the tail lights and the large air outlets underline the reduction in drag achieved over the vehicle as a whole

Purpose-built interior.